GB-2

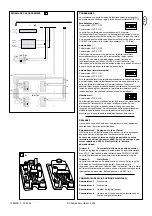

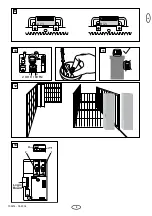

INSTALLATION OF DRIVE BASE PLATE -

The base plate for the drive can either be concreted in or, if appropriate,

welded into position. The place where the base plate is usually located

is shown on the installation overview. The concrete plinth needs to be of

an appropriate size (approx. 50cm x 50cm x 50cm).

Please note:

If it is impossible to precisely determine the height of

the plinth and the distance from the gate prior to installation, it is

advisable to mount the rack bars first and then concrete in the base

plate. Spacers are fitted to move the rack bars approx. 40mm

towards the inside.

The distance from the bottom edge of the rack bar to the base plate

is approx. 8 - 9cm. The base plate permits final height and depth

adjustments of several centimetres to be made, but you are advised

to work as precisely as possible from the outset.

MOUNTING MOTOR AND GEAR UNIT

The drive should be fitted on to the threaded bolts in the base plate.

The height should be set such that there is a gap of approx. 1 - 2mm

between the cog wheel and the rack bar. The weight of the gate should

not be borne by the cog wheel! Position the drive via the adjustment

holes such that its location vis-à-vis the rack bar complies with the

installation dimensions.

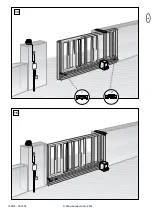

MOUNTING RACK BAR

The easiest way to fit the rack bar is to first place it on the motor's

drive cog, disengage the motor and, by pushing the gate further with

the rack bar, screwing the bar bit by bit firmly in position. In this way,

you ensure that the rail bar engages with the cog wheel in an optimum

manner. While doing this, do not forget to mark each fixing point.

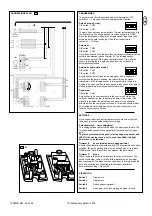

DRIVE RELEASE MECHANISM (MANUAL OPERATION)

The drive is equipped with a lockable release mechanism to enable

the gate to be operated manually in a power cut. The release

mechanism is shown in

fig. 7

with the clutch disengaging the link

between the cog wheel and the gear.

To release the drive:

Position the socket spanner appropriately and

turn it 180 degrees. Then turn the release lever 180 degrees too.

Finished.

FITTING LIMIT SWITCHES (TO GATE)

The limit switches are assembled as shown in

fig. 8

.

One limit switch magnet is designated A (1) and the other B (2).

Fit the limit switches on to the rack bar in those places where the

final travel positions are roughly expected to be. The magnet should

point towards the motor. The switch (contact) is located in the middle

of the motor. Screw the retaining clip only provisionally in place or

slot it lightly on to the rack bar.

Limit switch A (1) for gate closed; limit switch B (2) for gate

open.

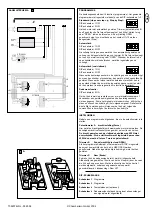

TESTING LIMIT SWITCH FUNCTIONALITY

(CHAMBERLAIN-CONTROL)

Disengage the gate and operate it only using your hands. Push the

gate into the respective final travel positions. The control unit should

already have been connected up.

On the control unit there are two red LEDs (LED 5 & LED 6) that go

out when the magnet on the gate trips the given switch. One LED is

for limit switch OPEN (LED 5) and the other for CLOSED (LED 6).

When you open the gate manually, the correct LED should go out. If

the wrong LED goes out, you need to swap limit switches A (1) and

B (2) around. Alternatively, the limit switch cables connected to the

control unit (17 + 19) can be swapped around. The distance between

the limit switch magnet and the switch on the drive should be as

small as possible. Under no circumstances should it be more than

25mm.

Important: If the limit switches have been swapped around, the gate

will open and not close after the set pause when in programme

selection (automatic) mode!

Caution: A sliding gate must run in a guide rail and should not

be able to leave the rail. This means end stops need to be fitted

for both directions!

BEFORE YOU BEGIN

There are many factors that are key to the choice of the right

sliding gate drive.

Assuming the gate is in good working order, the

most difficult aspect is getting the gate to move. Once the gate is in

motion, force requirements are in the main significantly reduced.

• Gate size:

Gate size is a very important factor. A light yet long

gate (long = + 5m) needs a far greater force to set it in motion

than a short, heavy gate does.

WIND CAN BRAKE A GATE'S MOVEMENT OR MAKE IT HARD

TO MOVE, THUS INCREASING FORCE REQUIREMENTS

SIGNIFICANTLY.

• Gate weight:

Gate weight is only an approximate indicator the

actual relevance of which can vary greatly.

Example: A light gate

that slides poorly is likely to need a stronger drive than a

heavy, smooth-sliding gate.

• Temperature:

Low outdoor temperatures make it difficult or, in

some cases, impossible to get the gate moving due, for instance,

to changes in the ground conditions. In such cases, a stronger

drive again might be necessary. High outdoor temperatures can

cause the thermal protection mechanism to be activated sooner.

• Operating frequency / Duty cycle:

Sliding gate drives have a

maximum duty cycle of approx. 30% (e.g. 30% per hour).

CAUTION:

The drives were not designed to be run for the maximum duty cycle

on a regular basis (permanent operation). If the drive gets too hot, it

switches itself off until it has cooled down to activation temperature.

The outdoor temperature and the gate itself are key factors

determining the drive's actual duty cycle

• Safety:

A sliding gate drive has to be fitted with a flashing lamp,

contact strips and, if necessary, with additional light barriers as safety

features. Please ensure that you comply with the standards and

regulations relevant to your particular case.

• Control unit:

The control unit was developed specifically with

safety aspects in mind.

It is already located under the drive hood

and wired up for right-hand installation as standard (motor to the

right of the gate). See figs. 2 - 3.

CHECK LIST - PRE-INSTALLATION WORK -

Prior to actual installation, please check that you have been provided

with all the parts indicated within the scope of supply.

Make sure your gate system is in good working order.

The gate must run smoothly, not jerkily and not make contact with

the ground at any point. Bear in mind that the ground can be several

centimetres higher in winter. The gate needs to be stable with as little

play as possible to prevent any lateral movement from occurring. The

easier the gate moves, the more sensitive the force setting needs to

be.

Make a note of the materials you still need and make sure you obtain

them prior to installation - adhesive anchors (strong plugs), screws,

stops, cable, distributor boxes, tools, etc.

OVERVIEW OF INSTALLATION

A general overview of installation can be found on the front sheet of

these instructions. The drive has to be installed behind the wall to

ensure that no part of it projects out into the gate opening. The motor

has to be mounted on the flush fitted base plate. The rack bar shown

has to be fitted to the gate with the fixing material supplied.

Decide which is the best height for fixing the rack bar to the gate and

use this to determine the installation dimensions for the motor unit

and base plate. Should the gate be unsuitable for fitting the rack bar

to it, a fixing profile (angle bracket, shaped tubing, etc.) needs to be

mounted first.

A

C

5

6 A

4

7

8

709207B-GB - 05.2004