GB-3

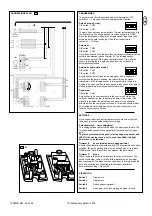

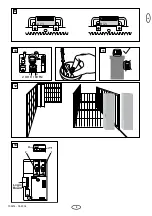

INFRARED SENSOR

The infrared sensor is a safety-enhancing facility and must be used.

Its installation location depends on the design of the given sliding

gate. Generally speaking, the light barrier is fitted at knee height

approx. 35cm above ground level. Infrared sensors comprise a

transmitter element and a receiver element which have to be located

opposite one another. A screwdriver can be used to open the light

barrier housing (plastic). The infrared sensor is fitted to the wall with

small screws and wall plugs. Usage of a single infrared sensor is a

minimum requirement; we recommend using two infrared sensors

(and other safety features if necessary).

Should a further infrared sensor be active for the OPEN direction of

travel, it has to be connected to contact 11 + 12 (stop). This is

necessary if the area behind the gate has to be secured. If contact

strips (accessories) are to be employed as additional safety features,

they also have to be connected to the stop contact.

The transmitter element needs a 2-pole cable, the receiver element a

4-pole one.

Cable cross-sectional area: 0.5mm

2

or more.

Voltage: 12/24 volt AC/DC.

Electrical connections: See control unit instructions.

FLASHING LAMP -

Usage of a flashing lamp is mandatory. It serves a safety-related

purpose in that it warns persons in the vicinity of the gate that the

given gate is moving.

The flashing lamp is fixed in position using screws and wall plugs.

The earthed cable has to be run up to connect with the lamp.

Normally speaking, it is installed at the highest possible point

(on a pillar).

Cable cross-sectional area: 0.75mm

2

, 3-pole

Voltage: 230 volt/AC.

Electrical connections: See control unit instructions.

KEY SWITCH (OPTIONAL)

The key switch can be used to activate the drive as well as open and

close the gate. Cable cross-sectional area: 0.5mm

2

or more.

Electrical connections: See control unit instructions.

INSTALLATION OF AN EXTERNAL ANTENNA (OPTIONAL)

An external antenna is not a mandatory requirement. A short antenna

is located on the control unit's radio adapter. Should the range of the

remote control need to be extended, fit an external antenna

compatible with 433 MHz (the ANT4X-EML model incl. 750 ohm

coaxial cable). It has to be connected up via the radio adapter on the

control unit (see control unit instructions). The best location for an

antenna is high up and as far away from electrical equipment as

possible. The short cable antenna that is supplied as standard and

pre-connected may then no longer be used.

Electrical connections: See control unit instructions.

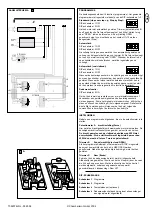

INITIAL OPERATION

Check gate functionality manually when the drive has been

disengaged. Electrical operation is only possible with the control unit

that is supplied as standard.

Electrical connections: See control unit instructions.

Always ensure that the mechanical and electrical safety requirements

relevant to the given system are complied with.

MAINTENANCE WORK

The drive mechanics are maintenance-free. Check at regular

intervals (monthly) that the gate hardware and the drive are all firmly

in place. Disengage the drive and check gate functionality. Only an

easy-running gate will work well with a drive. A drive is no substitute

for a poorly functioning gate.

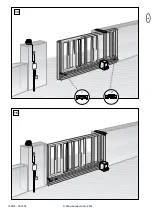

A sliding gate can also be secured by implementing on-site

measures (fence, wall, etc.).

See fig. 12.

TECHNICAL DATA - CONTROL UNIT

Voltage: 230V~

±10%

50Hz

Max. consumption:

10W

Max. drive supply:

230V~ 50Hz 700VA max

Infrared Sensor supply:

24V~ 0,5A max

Working temperature:

-25

O

C – 55

O

C

Operating modes:

Automatic / Semi-automatic / Step-by-step / Dead man

Max. running time:

120 sec

Pause period:

8 – 200sec

Dimensions:

109x145mm (without box)

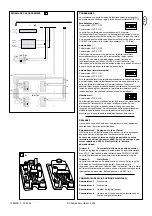

ELECTRICAL INSTALLATION

The control unit is designed to be installed in a special box

under the hood of the sliding gate drive and, as such, can be

ordered as an accessory if not already available. The control

unit can also be accommodated externally (on the wall) in a

watertight box (accessory).

The control unit should be the last item to be connected up, i.e.

mounting the drive, laying the necessary cable and fitting light

barriers (contact strips). If installation is to be performed in a

permanent location, a means of disconnecting the equipment from

the mains supply with a contact clearance of at least 3 mm is needed

(master switch). Humidity and water will destroy the control unit.

Always make sure that water, humidity and condensation cannot

enter the control unit. It is vitally important that all openings and cable

glands are sealed so that they are watertight.

INSTALLATION OF CONTROL BOX

The motor control unit is a microprocessor-controlled electronic

appliance featuring state-of-the-art technology. It is equipped with all

the connecting options and functions needed to guarantee safe

operation. The control box incorporating the motor control unit should

be installed with the cable intakes pointing downwards. It should not

be continuously exposed to direct sunlight. The electronic equipment

enables the pull and push forces to be set with great accuracy. If

installed and set correctly, the gate can be stopped manually.

When in motion, the gate can be stopped at any time by operating

the remote control, the push-button or the key-operated switch.

The gate must be fitted with a robust end stop for the OPEN and

CLOSED positions.

Generally speaking, the following minimum cable cross-

sectional areas must be adhered to:

• 100-230Volt 1,5mm

2

or more

• 0-24Volt 0,5mm

2

or more

Tips:

Bell wire is often problematic in practical use because it loses

too much voltage if long lengths of wire are used.

Segregate the cables in cable trunking, i.e. motor cable and light

barrier cable, especially in the case of key-operated switches and ON

switches (from the house wiring system) to prevent interference

where long lengths of cable are used.

9

A

10

11

12

TECHNICAL DATA

Voltage IN

Frequency

Power

Current rated

Torque

Capacitor

Therminal Overload

Protection

Motor Speed

Travel Speed

Duty Cycle

Working Temperatur

Range

Protection Class

Degree of Protection

Weight

approx. Gate Length

Max. Gate weight at

max. length (incl.

20% reserve)

HC100

230Volt

50Hz

300W

1.3A

9Nm

8

140

1400

12

30

-20

O

C - 55

O

C

IP44

I

9

5m

300kg

HC500

230Volt

50Hz

360W

1.5A

10Nm

10

140

1400

12

30

-20

O

C - 55

O

C

IP44

I

9

8m

500kg

709207B-GB - 05.2004