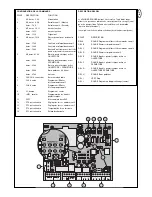

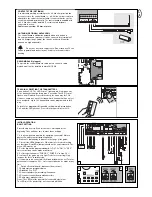

INSTALLATION OF THE CONTROL BOX

The control board was designed for installation in a special, waterproof

box (041FA277BX). Before fitting, measure the required distances and

determine the correct holes. Use a screwdriver to force the plastic out

of the holes. Insert threaded cable connections with strain relief, hold

the box against the surface on which it is to be mounted. Insert screws

through the mounting holes in the rear panel and tighten. The motor

control unit is a highly modern electronic unit controlled by a

microprocessor. It has all wiring facilities and functions required for safe

operation. Moisture and water will destroy the control board. Make sure

under all circumstances that water, moisture or storage moisture cannot

penetrate the control board. Make sure that all openings and cable

entries are sealed watertight. The control box with the motor control unit

is mounted with the cable entries facing down. It must not be permanently

exposed to direct sunlight. The electronics can be used for the precise

adjustment of the push-pull torque. The gate can be held by hand if the

fitting/setting is correct. During operation, the gate can be stopped at all

times via remote control, push-button or key-operated switch. The gate

wing requires a firm stop for the “OPEN” and “CLOSED” positions,

because the gate drives have no limit switch.

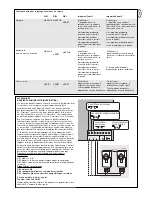

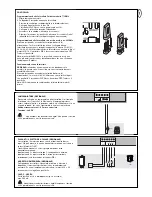

CURRENT DISTRIBUTION

The cable coming from the drive arm must be inserted into a

commercial, waterproof distribution box. A firm cable connection can

then be established from the distribution box to the control board. It is

frequently possible to lead the drive, that is fixed directly next to the

control board, directly into the box. Never lay distribution boxes under

the ground.

The following minimum cable cross-sections should be used:

• 100-230 volts 1.5 mm² or more more

• 0-24 volts 0.5 mm² or more more

Tips: Bell wires often cause problems when used, because they lose

too much voltage if lines are long. Disconnect the cables in the cable

trunkings i.e. the motor cable and the cable for the photocell, in

particular for key-operated switches and start buttons (coming from the

house), otherwise malfunctions are possible if lines are long.

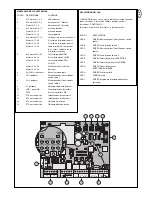

TECHNCAL DATA

Voltage:

230 V~ ±10 % 50 Hz

Max. consumption:

22 mA

Drive max.:

230 V~ 50 Hz 1000 W max

Power supply for accessories: 24 V~ 0.5 A max

Operating temperature: -25 ºC ÷ 55 ºC

Operating modes:

Standard/ standard & no self-hold (hold to run) for closing/

no self-hold (hold to run)

Max. running time:

80 sec

Rest time:

0 ÷ 150 sec

Dimensions:

124x152 mm (without box)

en-1

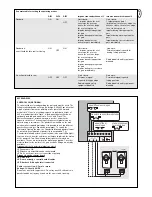

PLEASE START BY READING THESE IMPORTANT SAFETY RULES • SAVE THESE INSTRUCTIONS

This safety alert symbol means "Caution" - failure to comply with such an instruction involves risk of personal injury or damage

to property. Please read these warnings carefully.

This gate drive mechanism is designed and tested to offer appropriately safe service provided it is installed and operated in

strict accordance with the following safety rules.

Incorrect installation and/or failure to comply with the following instructions may result in serious personal injury or property

damage.

Installation and wiring must be in compliance with

your local building and electrical installation codes.

Power cables must only be connected to a properly

earthed supply.

Any entrapment possibility by the moving wing between

wing & walls must be secured with safety edges or IR-

sensors.

.

Disconnect electric power to the system before making

repairs or removing covers.

A disconnecting device must be provided in the

permanently-wired installation to guarantee all-pole

disconnection by means of a switch (at least 3mm

contact gap) or by a separate fuse.

When using tools and small parts to install or carry

out repair work on a gate exercise caution and do not

wear rings, watches or loose clothing.

Make sure that people who install, maintain or

operate the gate drive follow these instructions.

Keep

these instructions in a safe place so that you can refer to

them quickly when you need to.

Please remove any locks fitted to the gate in order to

prevent damage to the gate.

It is important to make sure that the gate always runs

smoothly. Gates which stick or jam must be repaired

immediately.

Employ a qualified technician to repair the

gate, never attempt to repair it yourself.

Keep additional accessories away from children. Do not

allow children to play with pushbuttons or remote controls.

A gate can cause serious injuries as it closes.

After the installation a final test of the full function of

the system and the full function of the safety devices

must be done.

The full protection against potential squeeze or

entrappment must work direct when the drive arms

are installed.

This drive cannot be used with a gate incorporating a

wicket door unless the drive cannot be operated with

the wicket door open.

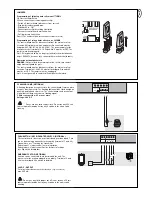

IMPORTANT FITTING AND OPERATING INSTRUCTIONS

ATTENTION

Summary of Contents for MotorLift HC600

Page 17: ...115o 90o 90o 90o 115o 115o 115o 90o 1 2 3...

Page 18: ...A 38 5cm 8 5cm 30cm 7 8cm 90 max 10cm C B 60 70cm 4 5 A B 6 7 8...

Page 19: ...9 11 12 10...

Page 22: ......