en-9

Gate opener does not function / does not respond

when button is pressed.

1. Connection to button is loose.

2. STOP switch connection is loose; STOP

LED is off.

3. Obstacle is blocking photocell in direction

of movement.

4. Safety edge is damaged or has

encountered an obstacle.

5. Gate opener is still released.

1. Check button and COM connections.

2. Check STOP switch connections

(STOP and COM).

3. Remove obstacle.

4. Remove obstacle and check

connections and wiring.

5. Lock gate opener.

The gate opener does not open the gate fully.

1. Are the post dimensions A+B correct?

2. Has the running time of the controller been

set correctly?

3. Has the force been set correctly?

1. Check A+B dimensions.

2. Reprogram as required – plus

approx. 3 seconds.

3. Correct force setting (gate opener

runs somewhat slower in windy

conditions).

The controller doesn’t respond when I alter the

Dip-switches.

Disconnect controller from power

supply, then alter Dip-switches.

“Timer to close” doesn’t work.

1. Only works if the 2-cable photocell

770E(ML) or 771E(ML) has been

installed.

2. Then turn “timer to close”

potentiometer in a clockwise direction.

The gate opener doesn’t respond at all; no LED is

on.

Possibly power failure.

1. Check conductor and zero conductor.

2. Check house fusing.

The gate opener is so strong that it bends the

gate and/or post.

1. A+B dimensions correct?

2. Force set too high?

3. Reinforce gate?

1. Check A+B dimensions.

2. Turn force potentiometer in an

anticlockwise direction.

3. Possibly screw gate opener to a

reinforcement plate (post).

Possibly fit reinforcement plate at point

of pull / push pressure (gate wing).

Use suitable screws and plugs

Immediately after the gate has started moving, it

stops and reverses.

Obstacle in area of gate.

Check area of gate for objects

The gate opener hums slightly but has no force

1. Capacitor is not correctly connected to the

brown and black cable.

2. Force has not been set.

3. The gate opener has been released.

1. Check wiring of capacitor.

2. Turn force potentiometer in a clockwise

direction.

3. Lock gate opener.

The gate opener only works when I press and

hold the button on the remote control.

1. Controller in ‘hold to run’ operating mode.

2. A safety facility is not working correctly

(photocell, safety edge).

1. Disconnect controller from power supply,

then alter Dip-switches.

2. Observe LEDs; find and rectify fault.

The gate opener doesn’t respond at all, although

the controller has been connected (LEDs are on).

1. Remote control has not been programmed.

2. LEDs indicate a fault.

3. Photocell connected incorrectly.

4. Jumper between STOP and COM missing.

5. Motor terminal possibly not connected

properly.

1. Programming remote control.

2. Find and rectify fault(s) (see description of

LEDs).

3. Check photocell connection / programming.

4. Connect simple jumper.

5. Check terminals and connections.

The gate opener stops suddenly and then restarts

only after a lengthy pause.

If the gate is operated constantly, the motor

will reach its cut-off temperature - protective

facility - as the gate opener is not designed

for permanent operation.

Allow motor sufficient time to cool (min. 15

minutes).

Can different A+B dimensions be used on the two

sides?

Generally speaking, yes, but the wings then open at different speeds. If the A+B dimensions

are altered significantly from the standard setting, the gate will run poorly and the fittings will

be subjected to greater stress (considerably reduced service life of installation).

The gate must follow a slope.

Not recommended! Change gate! The gate can move in an uncontrolled (dangerous) manner if

the gate opener has been released. A stronger force is needed in the upwards direction of the

slope and then, in the opposite direction, the gate opener’s force is too strong.

The force setting has been altered, but no

difference is apparent.

Disconnect the controller from the power supply for a few seconds in order to activate the

control board’s self-diagnosis functionality.

The remote control’s range is too short.

The installation of an external aerial is recommended as the controller with the short cable

aerial is located either behind the post or near ground level in most cases. The optimum

location of the aerial is as high as possible in all cases. An appropriate aerial with installation

kit can be obtained from Chamberlain as an accessory with the product ref. no. ANT4X-1EML.

The gate post is so thick that I am unable to

comply with the requisite A+B dimensions.

Reduce post thickness or shift gate location.

Summary of Contents for MotorLift HC600

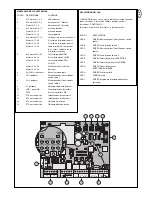

Page 17: ...115o 90o 90o 90o 115o 115o 115o 90o 1 2 3...

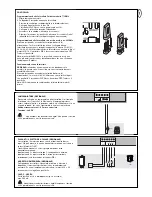

Page 18: ...A 38 5cm 8 5cm 30cm 7 8cm 90 max 10cm C B 60 70cm 4 5 A B 6 7 8...

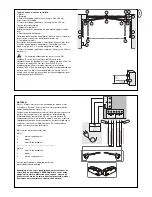

Page 19: ...9 11 12 10...

Page 22: ......