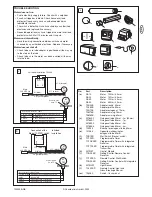

INSTALLATION

Rough- in or install conduit pipe to the connector box for the

electrical connecting line according to local building and

electrical codes.

Place the tube drive adapter

(7)

on the motor and fix the

drive adapter with the parts

(3 or 4)

.

Fix the square pin with the screws on the motor

(5 or 6)

.

Fully unroll the shutter

(a)

. Remove the shutter material

from the tube

(b)

. Remove the manual control

(c)

.

Remove the tube.

Push the motor

(1)

completely into the tube. The limit

switch operates only if the drive unit is fully inserted.

Ensure that the adapter ring is pushed fully home.

Do not

force it or strike it. Do not damage the tubular motor

by drilling!

Proceed according to the specific requirements for left-

sided

(a)

or right-sided

(b)

operation:

Secure the mounting bracket

(8)

to the wall (use suitable

screws and plugs).

Insert the motor

(a)

into the mounting bracket

(8)

and

secure it.

Make sure the set screws for the limit adjustments

are accessible.

Don’t return the shutter material to the tube yet!

ELECTRICAL CONNECTION

Never connect more than one motor to a timer or

wall switch without using a central module – (h)

(available as an accessory), i.e. one central module

is required for each connected motor.

The illustration also shows the wall bracket on the drive side

(b)

, the motor

(a)

; the steel tube

(c)

; the end cap

(d)

; and the

opposite wall bearing

(e)

.

For a

left-side

motor installation, follow the wiring diagram

exactly

as shown in the control accessory package.

For the correct direction of rotation in a

right-side

motor

installation, electrical wires (brown & black) must be

reversed

between the control accessory and the motor. (See instructions

packed with the accessory you have chosen).

Have the electrical hook-up done by a qualified electrician

in compliance with your local electrical code.

Accessories can be found in section L on page 4.

D

E

H

C

B

F

G

A

GB-3

SETTING THE LIMITS

Procedure for Adjusting

“Open” and “Close” Positions

(refer to figure I for lefthanded installation)

#1 Limit Setting for “Shutter Open”

+ = increase travel

– = decrease travel

#2 Limit Setting for “Shutter Close”

+ = increase travel

– = decrease travel

Please observe that the limits of the motor only

operate in a complete installation.

Read the following instructions carefully

before

making

any open or close limit adjustments.

To attach the shutter material on the tube, use ONLY the 3.9 x

6.5 mounting screws included (not suitable for RA10).

Otherwise, the drive might be damaged by screws which are

too long.

This instruction applies particularly to model RA10 (no

screws included). Use the appropriate fixing parts to

secure the shutter material to the tube. The drive may be

damaged by using screws which are too long.

IF ADJUSTMENTS ARE NEEDED, PROCEED AS FOLLOWS:

LIMIT ADJUSTMENT SCREW #1 - OPEN

Run the motor through an open cycle.

©

If motor stops before shutter is fully opened:

Turn set screw #1 and open the shutter until desired

position is reached.

©

If motor stops after shutter is fully opened:

Close shutter below desired position. Turn set screw #1 toward

– and open shutter again. Repeat this step as often as

necessary to reach the desired position

LIMIT ADJUSTMENT SCREW #2 - CLOSE

Run the motor through a close cycle.

©

If motor stops too soon (before shutter is fully closed):

Turn set screw #2 and close shutter again, until

desired position is reached.

©

If motor stops after shutter is fully closed:

Retract shutter above desired position. Turn set screw #2

toward – and close shutter again. Repeat this step as often as

necessary to reach the desired position.

I