33

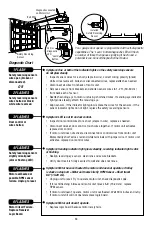

Having a Problem?

1. My door will not close and the light bulbs blink on

my motor unit:

The safety reversing sensor must be

connected and aligned correctly before the garage door

opener will move in the down direction.

• Verify the safety reversing sensors are properly

installed, aligned and free of any obstructions. Refer

to

Installation Step 10: Install The Protector System

®

.

• Check diagnostic LED for fl ashes on the motor unit

then refer to the

Diagnostic Chart

on the following

page.

2. My remotes will not activate the door:

• Verify your Multi-Function Door Control is

not blinking. If it is blinking, deactivate the Lock

Mode following the instructions for

Using the

Multi-Function Door Control.

• Reprogram remotes following the programming

instructions. Refer to

Programming

.

• If remote will still not activate your door, check

diagnostic LED for fl ashes on motor unit then refer to

Diagnostic Chart

on the following page.

3. My door reverses for no apparent reason:

Repeat

safety reverse test after adjustments to force or travel

limits. The need for occasional adjustment for the force

and limit settings is normal. Weather conditions in

particular can affect door travel.

• Manually check door for balance or any binding

problems.

•

Refer

to

Adjustment Step 2, Adjust the force.

4. My door reverses for no apparent reason after fully

closing and touching the fl oor:

Repeat safety reverse

test after adjustments to force or travel limits. The

need for occasional adjustment for the force and limit

settings is normal. Weather conditions in particular can

affect door travel.

•

Refer

to

Adjustment Step 1, Adjust the UP and DOWN

Travel Limits.

Decrease down travel by turning down

limit adjustment screw clockwise.

5. My lights will not turn off when door is open:

• The garage door opener is equipped with a security

light feature. This feature activates the light on

when the safety reversing sensor beam has been

obstructed. Refer to Operation section; Using the

Wall-Mounted Door Control, Light Feature.

6. My motor unit hums briefl y:

• First verify that the trolley is against the stop bolt.

• Release the door from the opener by pulling the

Emergency Release Rope.

• Manually bring the door to a closed position.

• Loosen the chain by adjusting the

outer nut

4 to 5

turns. This relieves the tension.

• Run the motor unit from the remote control or door

control. The trolley should travel towards the door

and stop. If the trolley re-engages with the door, pull

the Emergency Release Rope to disengage.

• Decrease the UP travel by turning the UP Travel

adjustment screw 2 full turns

away

from the arrow.

• Re-tighten the outer nut so the chain is a 1/4"

(6 mm) above the base of the rail. (When the door

is reconnected and closed, the chain will sag. This is

normal.)

• If the trolley does not move away from the bolt,

repeat the steps above.

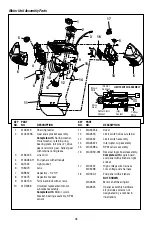

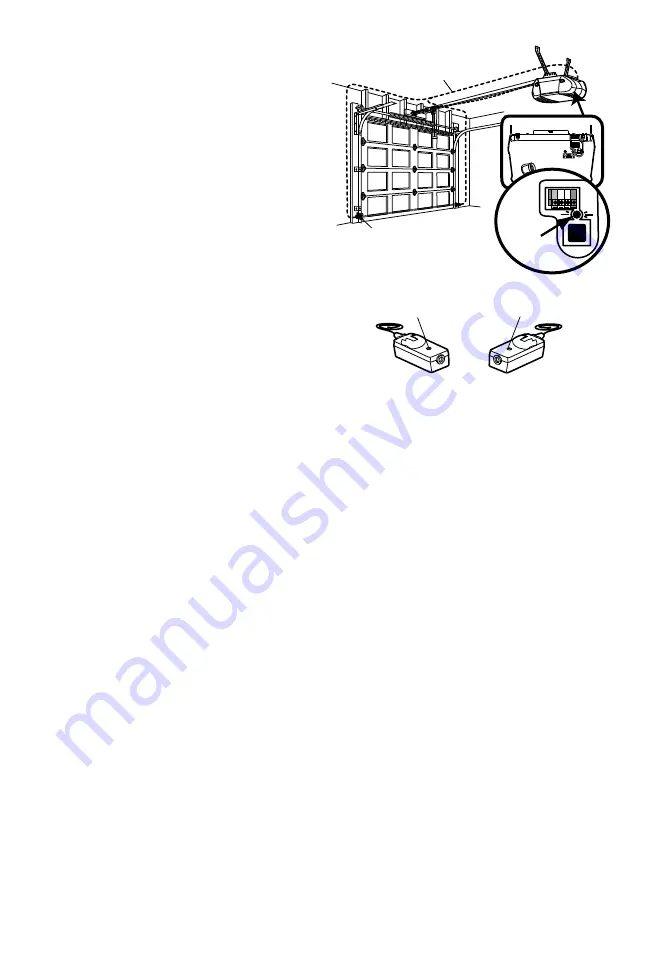

Sending Eye Safety Reversing

Sensor (Amber Indicator Light)

Receiving Eye Safety Reversing

Sensor (Green Indicator Light)

Bell Wire

Safety Reversing Sensor

“Learn”

Button

LED or

Diagnostic

LED