2

SAFETY

USAGE CLASS

UL325 ENTRAPMENT PROTECTION REQUIREMENTS

CLASS I – RESIDENTIAL VEHICULAR GATE

OPERATOR

A vehicular gate operator (or system) intended for use in garages or

parking areas associated with a residence of one-to four single families.

CLASS II – COMMERCIAL/GENERAL ACCESS

VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a commercial

location or building such as a multi-family housing unit (five or more

single family units), hotel, garages, retail store, or other buildings

accessible by or servicing the general public.

CLASS III – INDUSTRIAL/LIMITED ACCESS

VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in an industrial

location or building such as a factory or loading dock area or other

locations not accessible by or intended to service the general public.

CLASS IV– RESTRICTED ACCESS VEHICULAR GATE

OPERATOR

A vehicular gate operator (or system) intended for use in a guarded

industrial location or building such as an airport security area or other

restricted access locations not servicing the general public, in which

unauthorized access is prevented via supervision by security personnel.

The same type of device shall not be used for both entrapment

protection means. Use of a single device to cover both the opening

and closing directions is in accordance with the requirement;

however, a single device is not required to cover both directions.

This operator is provided with Type A. The installer is required to

install additional entrapment protection devices in each entrapment

zone.

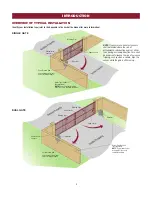

HORIZONTAL SLIDE AND SWING GATE OPERATOR

GATE OPERATOR ENTRAPMENT PROTECTION TYPES

Type A

Inherent (built into the operator) entrapment

protection system

Type B1

Non-contact sensors such as photoelectric sensors

Type B2

Contact sensors such as edge sensors

This vehicular gate operator must be installed with at least two independent entrapment protection means as specified in the table below.

To reduce the risk of INJURY or DEATH:

• READ AND FOLLOW ALL INSTRUCTIONS.

• NEVER let children operate or play with gate controls. Keep the

remote control away from children.

• ALWAYS keep people and objects away from the gate. NO ONE

SHOULD CROSS THE PATH OF THE MOVING GATE.

• Test the gate operator monthly. The gate MUST reverse on contact

with a rigid object or reverse when an object activates the non-

contact sensors. After adjusting the force or the limit of travel,

retest the gate operator. Failure to adjust and retest the gate

operator properly can increase the risk of INJURY or DEATH.

• Use the emergency release ONLY when the gate is not moving.

• KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual.

Have a qualified service person make repairs to gate hardware.

• The entrance is for vehicles ONLY. Pedestrians MUST use separate

entrance.

• SAVE THESE INSTRUCTIONS.

IMPORTANT SAFETY INFORMATION

Summary of Contents for RSW12U

Page 2: ......