26

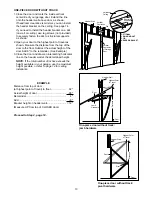

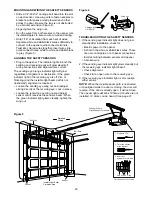

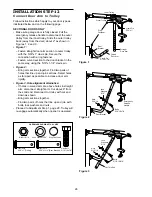

INSTALLATION STEP 12

Connect Door Arm to Trolley

Follow instructions which apply to your door type as

illustrated below and on the following page.

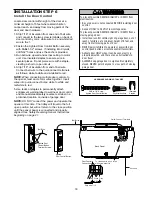

SECTIONAL DOORS ONLY

• Make sure garage door is fully closed. Pull the

emergency release handle to disconnect the outer

trolley from the inner trolley. Slide the outer trolley

back (away from the door) about 2" as shown in

Figures 1, 2 and 3.

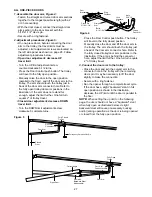

• Figure 1:

– Fasten straight door arm section to outer trolley

with the 5/16"x1" clevis pin. Secure the

connection with a ring fastener.

– Fasten curved section to the door bracket in the

same way, using the 5/16"x1-1/4" clevis pin.

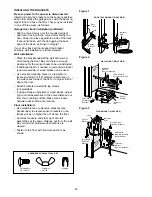

• Figure 2:

– Bring arm sections together. Find two pairs of

holes that line up and join sections. Select holes

as far apart as possible to increase door arm

rigidity.

• Figure 3, Hole alignment alternative:

– If holes in curved arm are above holes in straight

arm, disconnect straight arm. Cut about 6" from

the solid end. Reconnect to trolley with cut end

down as shown.

– Bring arm sections together.

– Find two pairs of holes that line up and join with

bolts, lock washers and nuts.

• Proceed to Adjustment Step 1, page 28. Trolley will

re-engage automatically when opener is operated.

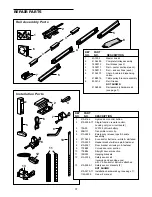

Ring

Fastener

Door

Bracket

Clevis Pin

5/16"x1-1/4"

Curved

Door Arm

Straight

Door Arm

Clevis Pin

5/16"x1"

Inner Trolley

Outer Trolley

Lock

Washers

5/16"

Nuts

5/16"-18

Door Bracket

Bolts

5/16"-18x7/8"

Emergency

Release

Handle

Lock

Washers

5/16"

Nuts

5/16"-18

Bolts

5/16"-18x7/8"

Cut This End

Figure 1

Figure 2

Figure 3

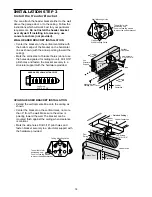

Lock Washer 5/16"

Nut 5/16"-18

Ring Fastener

Hex Bolt

5/16"-18x7/8"

Clevis Pin

5/16"x1" (Trolley)

Clevis Pin

5/16"x1-1/4" (Door Bracket)

HARDWARE SHOWN ACTUAL SIZE