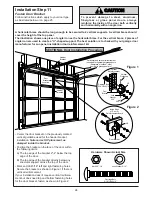

Lag Screws

5/16"x9x1-5/8"

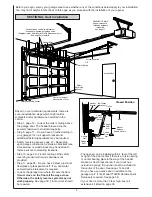

Highest

Point of Travel

(of Garage Door)

Vertical

Center

Line

Header

Wall

Garage

Door

UP

CEILING MOUNT ONLY

Wall

Mounting Holes

Optional

Wall Mounting

Holes

The nail hole is for positioning

only. You must use lag screws to

mount the header bracket.

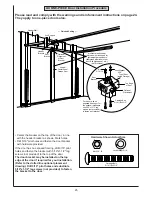

UP

CEILING MOUNT ONLY

Door

Spring

Header

Bracket

2x4

Structural

Support

Vertical

Center

Line

14

You can attach the header bracket either to the

wall above the garage door, or to the ceiling.

Follow the instructions which will work best for

your particular requirements.

Fasten the Header Bracket to the Wall

• Center the bracket on the vertical guideline with

the bottom edge of the bracket on the horizontal

line as shown (with the arrow pointing toward the

ceiling).

• Mark either set of bracket holes (do not use the

holes designated for ceiling mount). Drill 3/16" pilot

holes and fasten the bracket securely to a structural

support with the hardware provided.

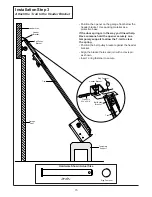

Fasten the Header Bracket to the Ceiling

Installation Step 2

Install the Header Bracket

Lag Screw

5/16"-9x1-5/8"

Hardware Shown Actual Size

UP

CEILING MOUNT ONLY

Ceiling Mounting Holes

The nail hole is for positioning only.

You must use lag screws to mount

the header bracket.

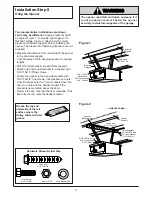

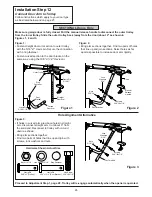

UP

Lag Screws

5/16"x9x1-5/8"

Garage

Door

Vertical

Center Line

Header

Wall

Finished

Ceiling

Header

Bracket

6" Maximum

Vertical

Center Line

Door

Spring

• Extend the vertical guideline onto the ceiling as

shown.

• Center the bracket on the vertical mark, no more

than 6" from the wall. Make sure the arrow is

pointing toward the wall. The bracket can be

mounted flush against the ceiling when clearance

is minimal.

• Mark holes designated for ceiling mount only. Drill

3/16" pilot holes and fasten bracket securely to a

structural support with the hardware provided.