GB-5

OPERATION

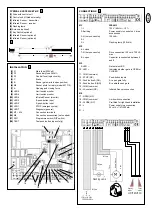

LED MONITORS

The system has six LED monitors which can be used for error

analysis or function control purposes.

LED 1

Yellow

ON = emergency stop vacant or

wire jumper available.

LED 2

Green

ON = signal from switch or radio

is present (open gate

fully).

LED 3

Green

ON = signal from switch or radio

is present (open gate

partially).

LED 4

Red

ON = Infrared Senor(s) vacant

or wire jumper available.

LED 5

Red

ON = OPEN limit switch

activated

LED 6

Red

ON = CLOSE limit switch

activated

LED 7

Red

Flashes slowly =

OK

Flashes quickly =

connection error and/or short

circuit in 120 volt area.

Both limit switches have been

ACTIVATED simultaneously!

9 – 10

It is possible to connect a gate

status LED that indicates the

given state of the gate.

OFF

= gate closed

Flashes slowly

= gate opening

ON

= gate open

Flashes quickly

= gate closing

FUSES

F1

3,15A, 250V

Main fuse

Protects the control

unit/transformer/flashing lamp/motor in

case of a short circuit

F2

0,5A, 250V

24AC supply

Reacts in case of short circuit or

overload on terminals 20 – 21

F3

0,315A, 250V

Fuse for logic circuitry

Push-button, emergency stop, light

barrier, receiver

Never use stronger fuses than those prescribed!

INITIAL OPERATION

DEFAULT SETTINGS

(1)

Connect drive in accordance with the attached connection

instructions

(2)

Put gate in semi-open position and engage motor

(3)

Adjust motor control unit to following default settings:

A

- Set force adjustment to 30%.

B

- Deactivate automatic close mode

(DIP switch 1 to OFF and 2 to ON)

.

C

- Set running time to 30%.

(4)

Switch on 120V power supply

(5)

Start motor control unit by pressing test push-button; the gate

should now open. If the gate closes, the connection leads to the

motor + limit switches (4 + 6) need to be swapped around.

Make sure you switch off mains supply prior to swapping leads

around!

(6)

Repeat steps 2 and 5 until desired functionality has been

established.

(7)

Adjust

potentiometer C

(brake) to set braking force for gate.

Small or light gates need no active brake.

INITIAL OPERATION (

CONTD

.)

(8)

Adjust

potentiometer A

to set the force generated by the

motors such that it is sufficient to just open and close the gate in

a proper manner.

(9)

Run through several complete cycles to test how the gate

behaves when operated and note whether it switches off when it

reaches the limit switches.

(10)

Test Infrared sensor functionality

(11)

Should you prefer a different programme (automatic closing

mode), wait until the end before changing the setting. Refer

back to the instructions to ascertain what impact the programme

selected has on functionality.

TEACHING IN REMOTE CONTROL

The radio remote control is licensed by the Post Office and costs

nothing to operate. It works on the basis of a private security code

(approx. 3.5 billion code options) that is pre-programmed via computer.

Your sliding gate drive can thus only be activated by a correspondingly

coded handset. The range obtained depends on the given local

environment. The receiver element of the motor control has an

integrated self-learn function. It can be set to the handset's pre-

programmed code by pressing the self-learn push-button

(fig. 13)

.

The control unit has two self-learn channels and is therefore able to

partially open a gate (pedestrian function) or open or close it fully via

appropriate operation of the handset. Should, for instance, channel 1

(1)

receive the handset's remote control code, the gate will only open

partially. If you teach the remote control on to channel 2

(2)

, you will

be able to open the gate completely.

To memorise the code, all you need do is press the button of your

choice on the handset and keep it depressed while, at the same time,

briefly pressing the self-learn button on the electronic unit with the

other hand.

Repeat this procedure for all handsets. Please note:

If

you release the given push-button before the self-learn LED has

stopped flashing, the remote control code will not be accepted.

DELETION OF PROGRAMMED REMOTE CONTROL CODE

Press the appropriate self-learn button

(1 or 2)

on the receiver

control board for approx. 10 seconds until the self-learn LED

extinguishes. The codes previously 'learned' and allocated to the

given self-learn button have thus been deleted.

REPROGRAMMING

For reprogramming purposes, the coding procedure mentioned

above should be repeated for all the remote controls in use and/or

their appropriate operating buttons.

The radio remote control's range varies according to the given local

environment. Keep the push-button on the handset depressed until

such time (approx. 2 seconds) as the gate is seen to move.

In the frequency ranges licensed by the German Post Office for gate

drives, there are also radio-operated systems in use for medical,

industrial, scientific, military and private purposes with, in some

cases, very powerful transmitting capabilities. Should you be in the

vicinity of such systems, this may cause your radio remote control to

suffer from reduced range or temporary interference.

Your radio remote control is digitally coded, i.e. accidental operation

of the gate drive is more or less impossible.

13

D e c l a r a t i o n o f C o n f o r m i t y

Automatic Gate Opener..........................................................SLY500E/K-120

as well as the Control unit ................................................................CB2-120

is in conformity to the applicable

sections of Standards.................................................EN55014, EN61000-3,

..........................................................EN60555, EN60335-1, & ETS 300 683

per the provisions & all amendments

of the EU Directives .................................................73/23/EEC, 89/336EEC

D e c l a r a t i o n o f I n c o r p o r a t i o n

Automatic Gate Opener Models SLY500E/K-120 and the control unit

CB2-120, when installed and maintained according to all the Manufacturer’s

instructions in combination with a Gate, which has also been installed and

maintained according to all the Manufacturer’s instructions, meets the

provisions of EU Directive 89/392/EEC and all amendments.

I, the undersigned, hereby declare that the equipment

specified above and any accessory listed in the manual

conforms to the above Directives and Standards.

Chamberlain GmbH

D-66793 Saarwellingen

May, 2002

Colin B. Willmott

Chief Engineer