1.2 TECHNICAL FEATURES

Fig. 1

A. Actuators

• 12V d.c. Motor

• Maximum thrust: 150N on the closing edge

• Piston rod speed: 1.5cm per sec.

• Possibility of continuous work (for a short period of time)

• Operating temperature: -15

0

to +45

0

• Protection degree: IP44

• E-lock connection

• Pedestrian function

• External light feature

B. Electronic control

• Plastic housing with IP44 protection degree, provided with No. 3+2

fairleads

• Control card

• 40 amp. relays

• 12V a.c. power supply input; 12 V d.c. outputs

• Double working program: Manual/Automatic

• Power supply warning LED

• Toroidal transformer - CE - 230/120V 50/60Hz 12V 100W

C: Transmitter

433.92MHz quartz transmitter in compliance with norms

I-ETS 300 220, PPT approved.

D: Keyswitch (not included)

E: Flashing lamp

• Plastic housing with IP44 protection degree provided with fairlead

• Lamp holder

• 12V 10W max. bulb

F - L: Adjustable Fixation system

I: Unlocking key

M: Pair of 12V photocells

N: Antenna with cable

1.3 HOW TO OPERATE THE DEVICE

Fig. 2

The pulse is sent to the remote control and is received by the

electronic programmer which provides to supply the energy to motors

which drive the gate wings. A second pulse will provide for the wings

closing. By adequately programming the equipment, one is able to

make the wings close automatically. The Flashing lamp will warn the

wings are moving. The system is designed to last many years and NO

MAINTENANCE is needed.

At intervals wash the actuators with water and soap.

The actuator piston rod made of stainless steel has NEVER to be

lubricated.

1.4 SAFETY ADVISES

Fig. 12

The system is provided with a crushing-proof electronic safety device

controlled by microprocessor. Check the perfect alignment of the gate

hinge pivots for a correct adjustment. The gate mutst be in proper

working condition in order to function correctly with the opener. A gate

stop is necessary for both the open and closed postitions.

1.5 FOR HIGHER SAFETY

Fig. 14 & 15

We advise to install one or two pair of photocells. They shall provide

for the reopening of the wings in case an object obstructs their way.

We also advise to comply with norms concerning automation in force

in the various countries (refer to 1.7 Compliance to norms).

1.6 EMERGENCY CONTROL

Fig. 3

In case the system fails, the gate can be manually opened.

Insert the triangular key inside the triangular plug placed over the

motors, then turn counter-clockwise till the stop. Motors shall unlock.

The inverse operation restores the gate automation.

1.7 COMPLIANCE TO NORMS

The equipment is in compliance with EEC directives: EEC 89/392

EN61000-3-2 EN61000-3-3. EN55014 ETS 300 683 ENV 50141.

1-ETS 300-220 CEPT T/R 01-04. Class II equipment.

EEC 72/23 EN60335/1, EN60529/II.

TÜV GS APPROVAL.

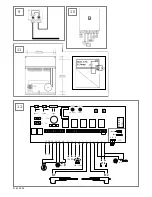

2.0 ACTUATORS ASSEMBLY TO PLATE

Fig. 4-7

Assemble the adjustable plate and fix it to the wall.

This operation is extremely important as it shall determine the

following parameters:

1. Gate opening speed

2. Actuator thrust strength

Fundamental elements to make this choice are the following:

1. The gate size (weight/length)

2. Pillar size

You will find a series of sizes to determine the positioning of plate with

respect to the gate rotation axis (hinge pivot) (Fig. 6).

For gate whose length is longer than 150cm, consider “B” measures

higher than 10cm (Fig. 7 - B is more than 10cm).

Some standard advised measures are:

Gates not exceeding 150cm.

A = 12cm / B = 12cm

Gates exceeding 150 - 200cm

A = 14cm / B = 14cm

Remind the higher is “B” measure, the slower the gate will open.

Figure 7: Maximum thrust strength allowed: 150N

In order to be sure not to exceed 15kg of thrust strength, do NOT use

measures shown in the blackened boxes of Fig. 7. In case it were

necessary to use those measures, it is compulsory to install a double

pair of safety photocells.

2-GB

709145B-GB - 05.2004

Summary of Contents for WGO200

Page 23: ...ca 700mm 1 2 3 4 5 01 05 2004 ...

Page 24: ...maximal 1100mm 6 1100mm max 7 01 05 2004 ...

Page 25: ...3 4 8 01 05 2004 ...

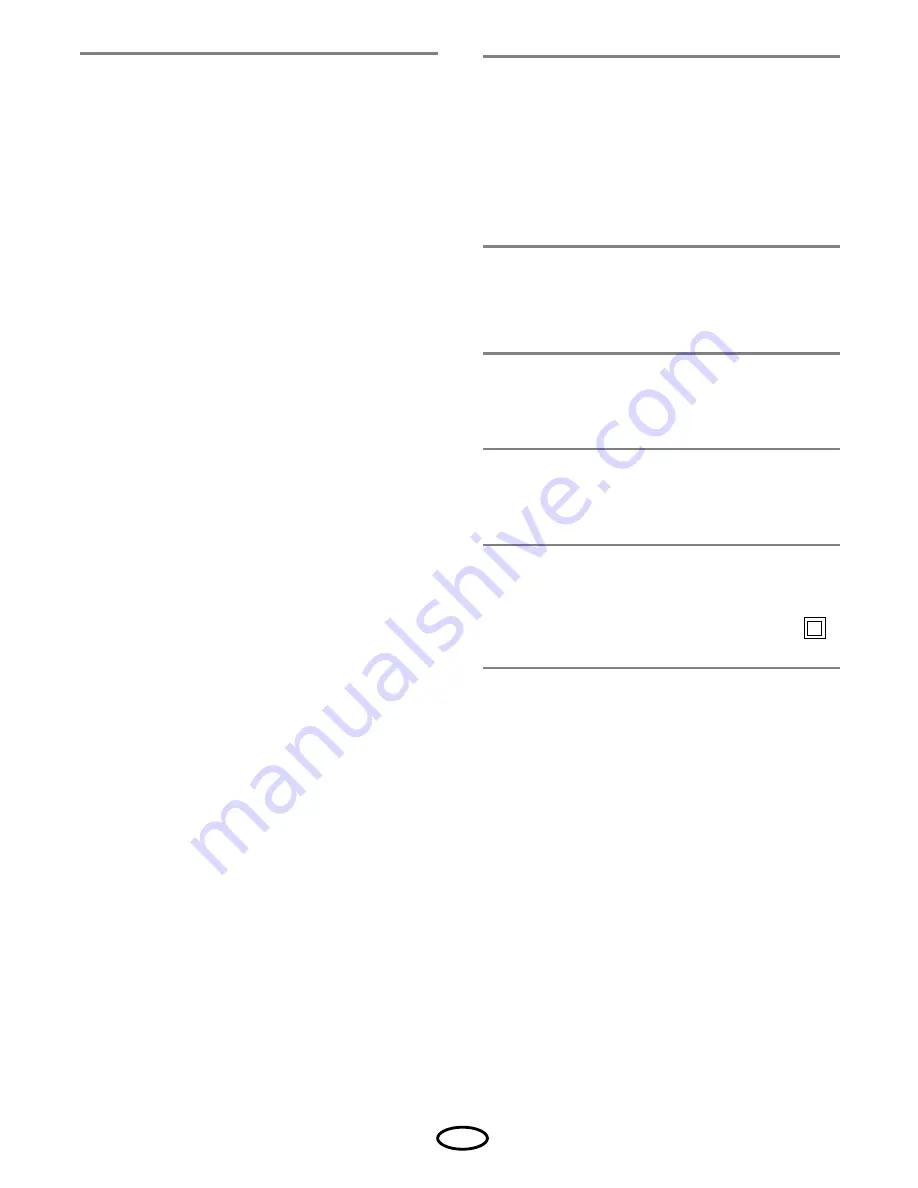

Page 27: ...13 2 1 2 1 Module 433MHz 418MHz 27MHz Logic Board 01 05 2004 ...

Page 28: ...12V 12V NC min 0 5 mm 2 NC C NO 10 11 1 2 10 11 1 2 5m max 14 15 01 05 2004 40 cm ...