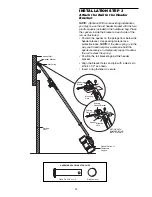

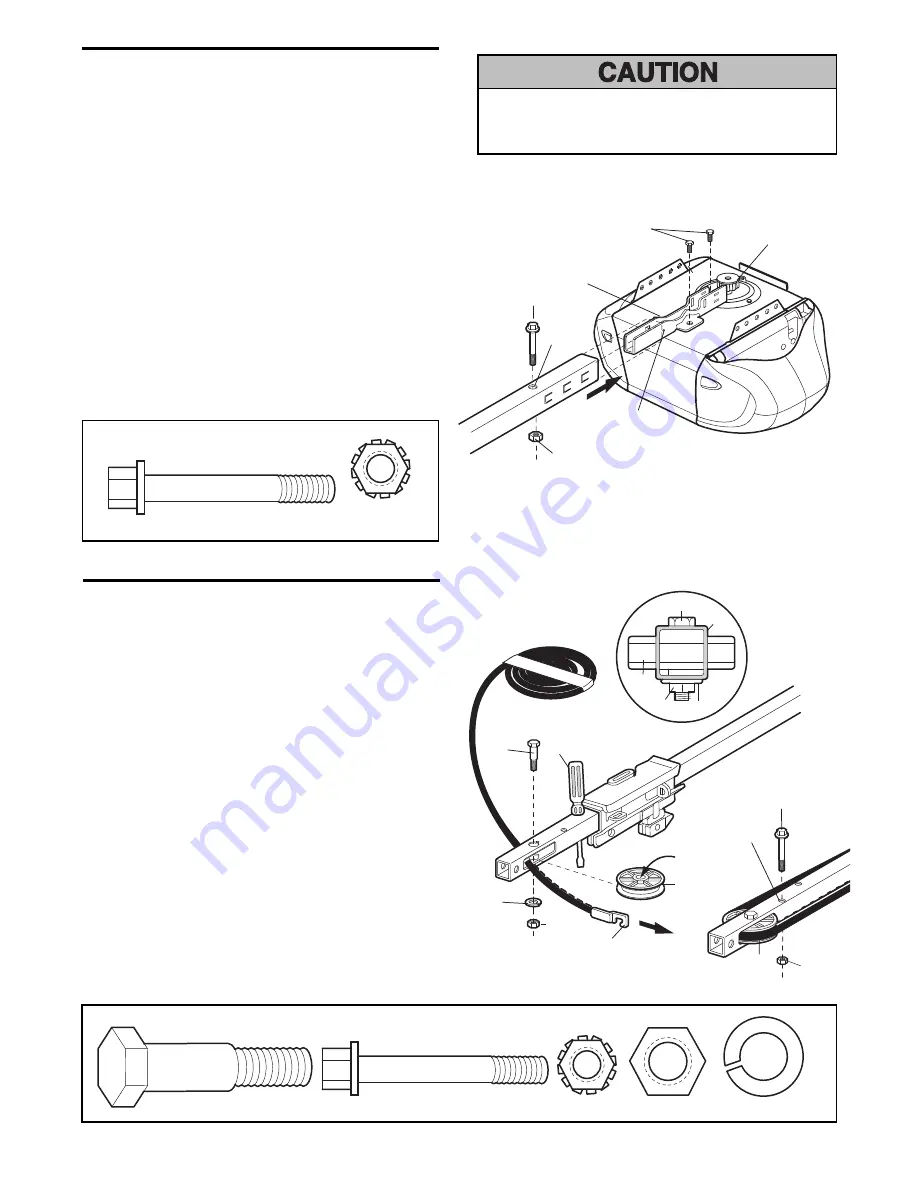

9

To avoid SERIOUS damage to garage door opener, use

ONLY those bolts/fasteners mounted in the top of the

opener.

ASSEMBLY STEP 2

Fasten the Rail to the Motor Unit

•

Insert a 1/4"-20x1-3/4 bolt into the cover protection

bolt hole on the back end of the rail as shown.

Tighten securely with a 1/4"-20 lock nut.

Do

NOT overtighten.

•

Remove the two bolts from the top of the motor

unit.

•

Place the “U” bracket, flat side down, on the motor

unit and align the bracket holes with the bolt holes.

Fasten with the previously removed bolts.

•

Align the rail assembly with the top of the motor

unit. Slide the rail end onto the “U” bracket,

all the

way to the stops that protrude on the top and sides

of the bracket.

ASSEMBLY STEP 3

Install the Idler Pulley

•

Lay the belt beside the rail, as shown. Grasp the

end with the hooked trolley connector and pass

approximately 12" (30 cm) of belt through the

window. Keep the ribbed side toward the rail, and

allow it to hang until Assembly Step 5.

•

Remove the tape from the idler pulley. The inside

center should be pre-greased. If dry, regrease to

ensure proper operation.

•

Place the idler pulley into the window as shown.

•

Insert the idler bolt from the top through the rail

and pulley. Tighten with a 3/8" lock washer and nut

underneath the rail until the lock washer is

compressed.

•

Rotate the pulley to be sure it spins freely.

•

Insert a 1/4"-20x1-3/4 bolt into the trolley stop hole

in the front of the rail as shown. Tighten securely

with a 1/4"-20 lock nut.

Motor Unit

Sprocket

"U" Bracket

Lock Nut

Bolts

SLIDE RAIL TO STOPS

ON TOP AND SIDES

OF BRACKET

Cover

Protection

Bolt Hole

Bolt

Idler

Pulley

Trolley

Stop Hole

Bolt

Trolley

Connector

Pulley

Rail

Bolt

Nut Washer

Lock Washer

3/8"

Nut 3/8"

Idler

Bolt

Screwdriver

Idler Pulley

Grease

Inside Pulley

Lock

Nut

Lock Nut

1/4"-20

Bolt 1/4"-20x1-3/4"

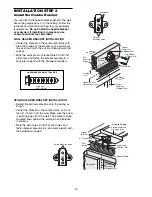

HARDWARE SHOWN ACTUAL SIZE

Nut 3/8"

Lock Washer 3/8"

Idler Bolt

Lock Nut 1/4"-20

Bolt 1/4"-20x1-3/4"

HARDWARE SHOWN ACTUAL SIZE