100402 - 2000W DUAL FUEL INVERTER GENERATOR

MAINTENANCE

24

To prevent accidental starting, remove the spark plug wire

before performing any service. Make sure spark plug wire end

does not rest on any metal parts.

Changing the Engine Oil

Change oil when the engine is warm. Refer to the oil

specification to select the proper grade for your operating

environment.

1. Set the generator on top of a work bench or table.

2. Remove the maintenance cover.

3. Remove the oil filler cap.

4. Tilt the generator on its side and allow the oil to drain

completely.

5. Add oil according to “Add Engine Oil” on Assembly

section. DO NOT OVERFILL. Oil not included for routine

maintenance.

MAX

OIL DIP STICK

6. Reinstall the maintenance cover.

7. Dispose of used oil at an approved waste management

facility.

NOTICE

Once oil has been added, a visual check should show oil

about 1-2 threads from running out of the fill hole. If using

the dipstick to check oil level, DO NOT screw in the dipstick

while checking.

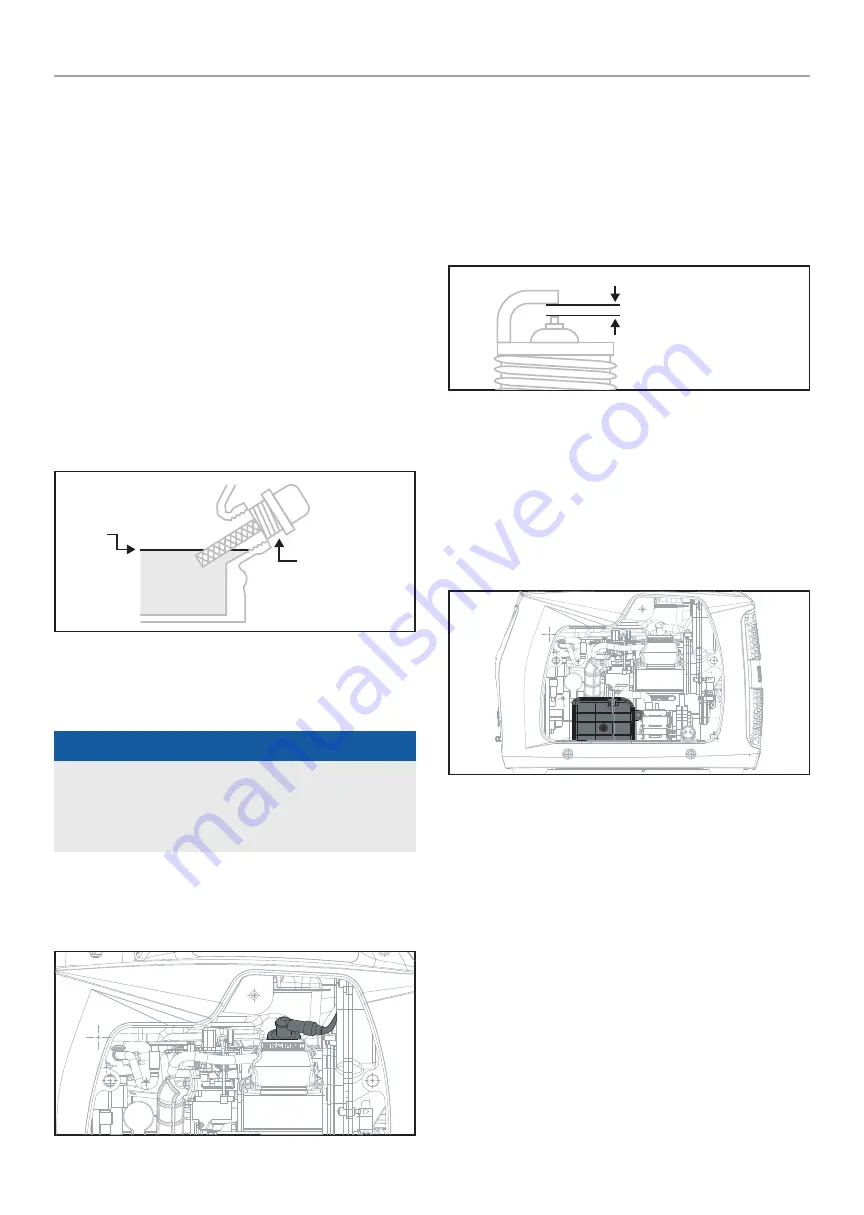

Cleaning and Adjusting the Spark Plug(s)

1. Remove the maintenance cover.

2. Remove the spark plug wire from the spark plug.

3. Use a spark plug socket tool (not included), or a

13/16 in. (21 mm) socket (not included) to remove the plug.

4. Inspect the electrode on the plug. It must be clean and not

worn to produce the spark required for ignition.

5. Make certain the spark plug gap is

0.024-0.028 in. (0.6-0.7 mm).

SPARK PLUG GAP

6. Refer to the spark plug types in

Specifications when

replacing the plug.

7. Firmly re-install the plug.

8. Attach the spark plug wire to the spark plug.

9. Reinstall the maintenance cover.

Cleaning the Air Filter

1. Remove the maintenance cover.

2. Locate the air filter plastic cover. Remove the screw using

a Phillips head screwdriver.

3. Remove the foam element.

4. Wash in liquid detergent and water. Squeeze thoroughly dry

in a clean cloth.

5. Saturate in clean engine oil.

6. Squeeze in a clean, absorbent cloth to remove all excess

oil.

7. Place the filter in the assembly.

8. Reattach the air filter cover.

9. Reinstall the maintenance cover and tighten the cover

screw securely.