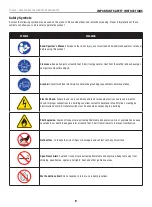

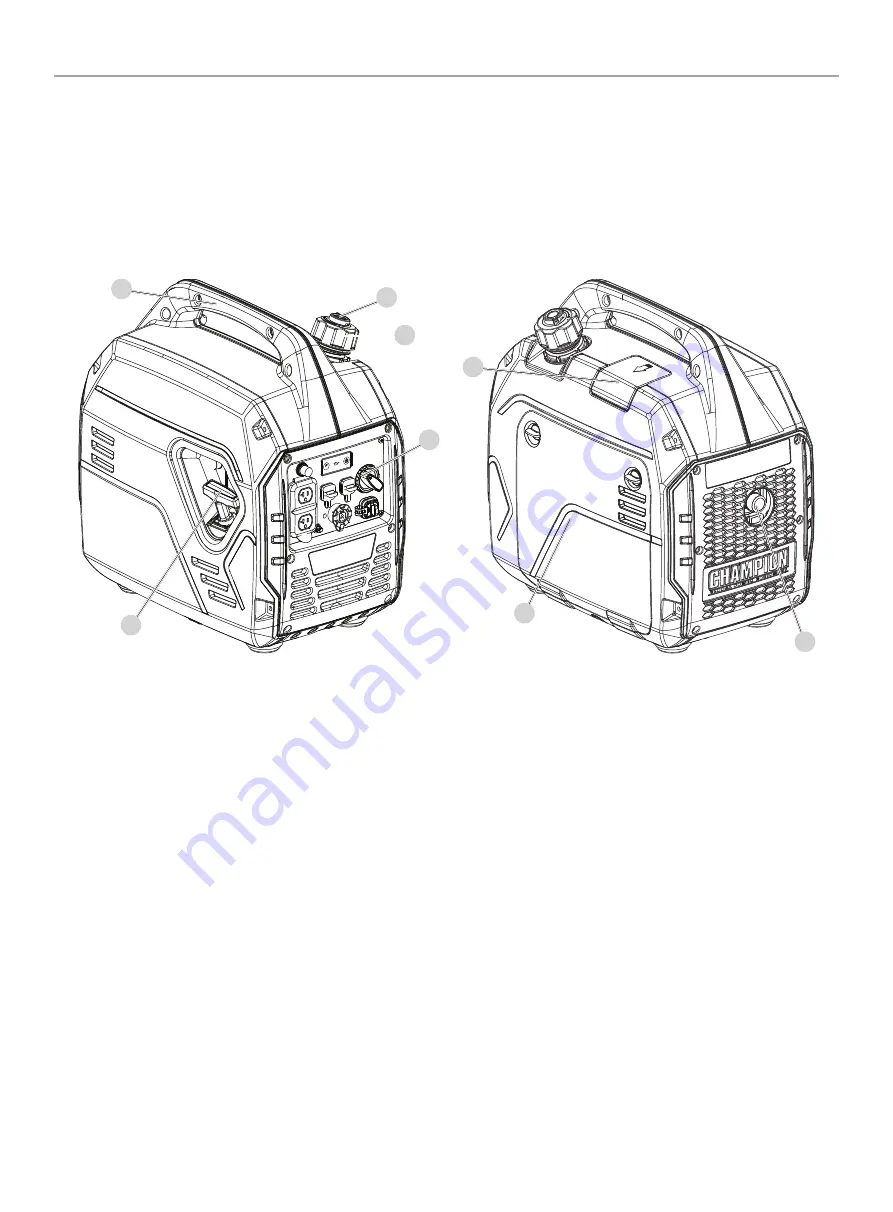

100899 - 2500W DUAL FUEL INvERTER GENERATOR

CONTROLS AND FEATURES

12

CONTROLS AND FEATURES

Read this operator’s manual before operating your generator. Familiarize yourself with the location and function of the controls and

features. Save this manual for future reference.

Generator

1.

Carrying Handle

–

Used to lift or carry the unit.

2.

Recoil Starter

– Used to manually start the engine.

3.

Control Panel

–

See

Control Panel

section.

4.

Fuel Cap

– Remove to add fuel.

5.

Fuel Lever Vent

– Turn this valve to the “ON” position to

supply air to the tank.

6.

Spark Plug Access Cover

7.

Maintenance Cover

8.

Muffler

ECO

1

2

3

7

8

6

4

5