100722 - 3500 Lb. (1588 kg) WiNch

OPERATiON

13

OPERATiON

general Tips for Safe Operation

Your 100722 winch is rated at a 3,500 lb (1,588 kg)

capacity in first layer (max) when spooling the first rope

layer on the drum. Overloads can damage the winch,

motor and/or synthetic rope. For loads over 1,750 lb.

(794 kg) we recommend the use of the pulley block/

snatch block to double the synthetic rope line. This will

aid in two ways:

–

reduce the number or rope layers on the drum,

as well as,

–

reduce the load on the rope by as much as 50%.

When doubling the line back to the vehicle, attach to the

tow hook, frame or other load bearing part. The vehicle

engine should be kept running during operation of the

winch to minimize battery drain and maximize power and

speed of the winch. If the winch is used for a considerable

time with the engine off the battery may be drained and

too weak to restart the motor.

Get to know your winch before you actually need to use

it. We recommend that you set up a few test runs to

familiarize yourself with rigging techniques, the sounds

your winch makes under various loads, the way the rope

spools on the drum, etc.

Inspect the synthetic rope and equipment before

each use. A frayed or damaged rope shall be replaced

immediately. Use only manufacturer’s identical

replacement rope with the exact specifications.

Inspect the winch installation and bolts to ensure that all

bolts are tight before each operation. Store the remote

control inside your vehicle in a place that it will not be

damaged.

Any winch that appears to be damaged in any way,

is found to be worn, or operates abnormally MUST

BE REMOVED FROM SERVICE UNTIL REPAIRED. It is

recommended that the necessary repairs be made by a

manufacturer’s authorized repair facility.

Pull only on areas of the vehicle as specified by the

vehicle manufacturer. Only attachments and/or adapters

supplied by the manufacturer are to be used.

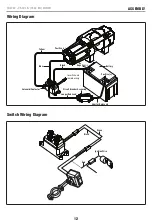

Self Recovery

Locate a suitable anchor such as a strong tree trunk or

boulder. Always use a sling as an anchor point.

Your winch is equipped with a aluminum hawse to help

guide the synthetic rope and to reduce binding on short

side pulls. Do not winch from an acute angle as the

synthetic rope will pile up on one side of the drum causing

damage to synthetic rope and the winch.

Correct

Incorrect

Short pulls from an angle can be used to straighten the

vehicle. Long pulls should be done with the synthetic rope

at a 90° angle to the winch/vehicle. When pulling a heavy

load, place a blanket or jacket over the synthetic rope five

or six feet from the hook.

In the event of a broken cable it will dampen the snap

back. For additional protection open the hood of the

vehicle. For pulls over 1,750 lb. (794 kg), we recommend

the use of the snatch block/pulley block to double line the

synthetic rope.