100776 - 10,000 LB. (4536 KG) WINCH

MAINTENANCE

13

MAINTENANCE

The owner/operator is responsible for all periodic

maintenance.

Complete all scheduled maintenance in a timely manner.

Correct any issue before operating the winch.

!

WARNING

Never operate a damaged or defective winch.

!

WARNING

Improper maintenance will void your warranty.

"

NOTICE

For service or parts assistance, contact our help line

at 1-877-338-0999.

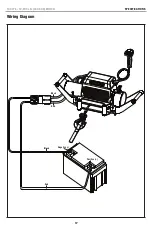

Lubrication

All moving parts within the electric winch have been

lubricated using high-temperature lithium grease at the

factory. No internal lubrication is required. Lubricate rope

assembly periodically using a light penetrating oil.

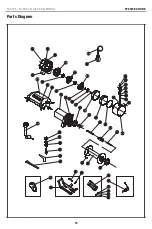

Steel Rope Replacement

It is recommended that any modifications be performed

by a manufacturer’s authorized repair facility, and that

only manufacturer-supplied parts be used.

1. Move the clutch to the “Out” position.

2. Extend rope to its full length. Note how the existing

rope is connected to the inside of the drum.

3. Remove old rope and attach new one.

4. Retract rope onto drum, being careful not to allow

kinking.

Synthetic Rope Replacement

(Optional)

1. It is recommended that any modifications be

performed by a manufacturer’s authorized repair

facility, and that only manufacturer-supplied parts

be used.

2. Move the clutch to the “Out” position.

3. Extend synthetic rope to its full length. Note how

the existing rope is connected to the inside of the

drum.

4. Remove old synthetic rope and attach new one.

5. Retract synthetic rope onto drum being careful not

to allow kinking.

Synthetic Rope

Periodically rinse the synthetic rope with water to

remove any sand, dirt, mud, or debris that can become

embedded or build up in the rope during use. This will

help extend the life of the rope.

"

NOTICE

Inspect rope before and after each use. If rope

becomes frayed it must be replaced.