201162 - 4000 Lb. (1,814 KG) WiNch

ASSEMbLY

10

contactor/Solenoid Location

Find a location for the contactor/solenoid. It is

recommended that the contactor/solenoid be mounted

close to the battery in a clean, dry location. Make sure

the location chosen allows for sufficient clearance from

all metal components. Drill mounting holes if required.

Once a location is found, DO NOT install the unit until all

wiring is completed (see wiring section).

NOTicE

Terminals coming in contact with metal will cause a

direct short, possibly causing contactor/solenoid and/

or battery damage.

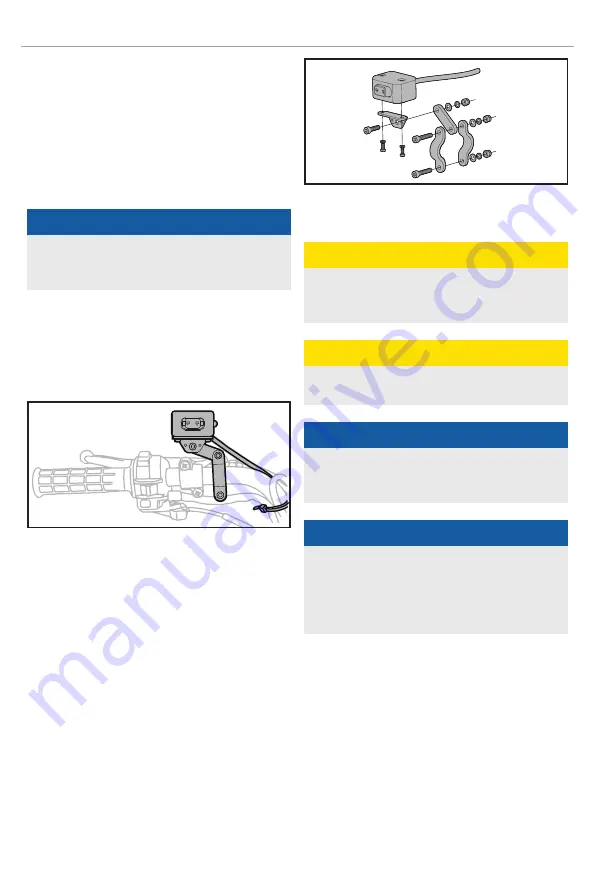

installing the Mini-Rocker Switch

1. Decide which handlebar the mini-rocker switch will

be mounted on. The mini-rocker switch is usually

installed on the left handlebar.

2. Use a piece of electrical tape (not provided) around

the handlebar to help prevent rotation of the mount.

Loosen the hardware and mount to the handlebar.

Tighten the mini-rocker switch in place. DO NOT

overtighten or tighten/clamp over any hoses or

cables.

Once the mini-rocker switch is mounted, the wires

can be routed back to where the solenoid/contactor

is located.

Make sure the handlebars have full range of motion

and then secure the mini-rocker switch’s cable with

the supplied cable ties.

Wiring the Winch

cAUTiON

NEVER

route electrical cables across any sharp

edges, through and/or near moving parts, or near

parts that may become hot.

cAUTiON

Battery cables should NOT be drawn tight. Leave

some slack for cable movement.

NOTicE

You may need to use a test light to locate a suitable

wire. The wire should only have power when the key is

in the ON position.

NOTicE

Depending on the location of the solenoid/contactor,

you may need to use the black and red cables in place

of the yellow and blue, and the yellow and blue in

place of the red and black. Just remember that this

also changes the diagram.

1. Connect the yellow and blue cables to the motor

terminals on the winch. (Yellow to the positive

(+) terminal of the motor. Blue to the negative (-)

terminal of the motor). Tighten the terminal nuts

on the motor. DO NOT over tighten. Route the other

ends to the solenoid/contactor location.

2. Connect the yellow and blue cables to the solenoid/

contactor (yellow to yellow and blue to blue).

DO NOT tighten nuts.