REV 71531-20140505

18

71531

ENGLISH

Adjustments

The air-fuel mixture is not adjustable. Tampering with

the governor can damage your generator and your

electrical devices and will void your warranty. CPE

recommends that you contact our service line at

1-877-338-0999 for all other service and/or adjustment

needs.

Maintenance Schedule

Follow the service intervals indicated in the following

maintenance schedule.

Service your generator more frequently when operating

in adverse conditions.

Contact our helpline at

1-877-338-0999 to locate the

nearest Champion Power Equipment certified service

dealer for your generator or engine maintenance needs.

Use a damp cloth to clean exterior surfaces of the engine.

Use a soft bristle brush to remove dirt and oil.

Use an air compressor (25 PSI) to clear dirt and debris

from the engine.

Cleaning

DO NOT spray engine with water.

CAUTION

Water can contaminate the fuel system.

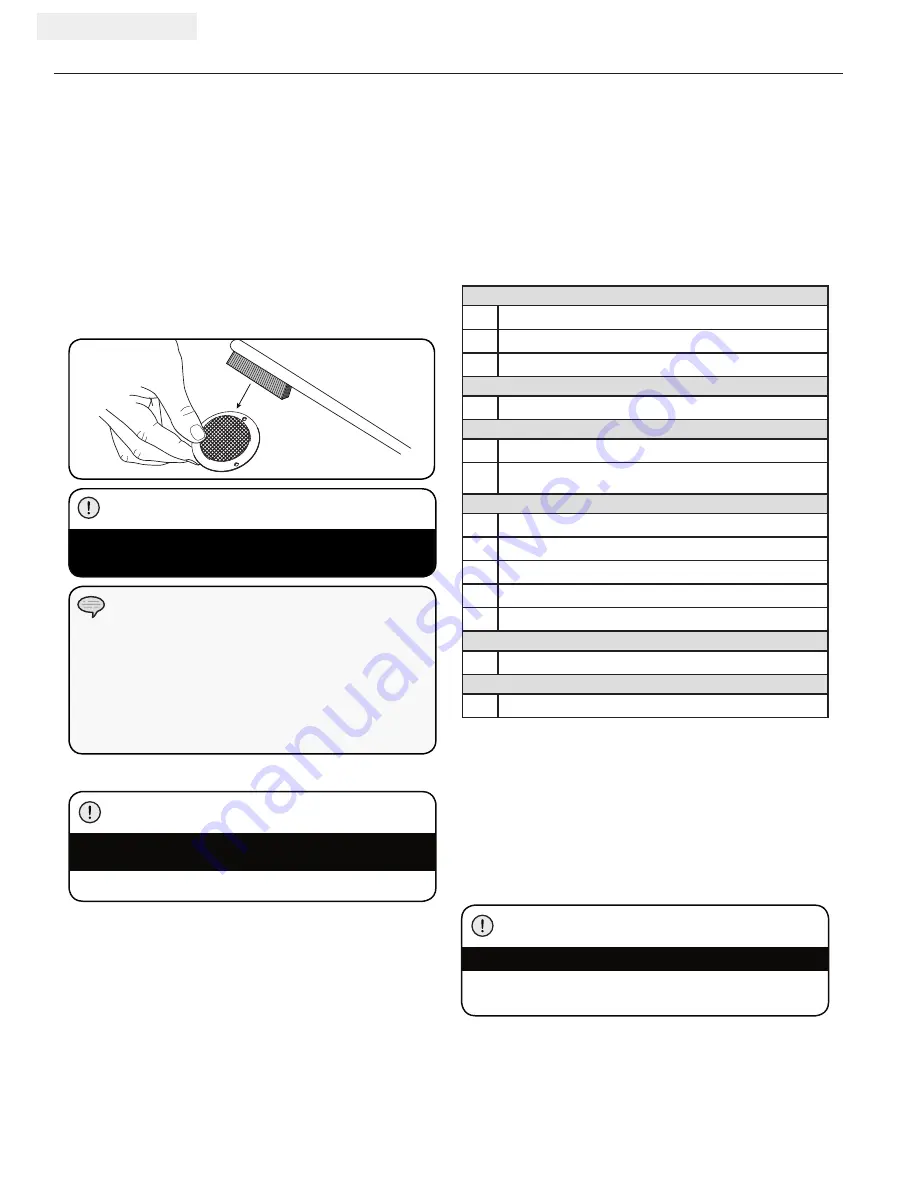

Spark Arrester

1. Allow the engine to cool completely before servicing

the spark arrester.

2. Remove the three screws holding the cover plate

which retains the end of the spark arrester to the

muffler.

3. Remove the spark arrester screen.

4. Carefully remove the carbon deposits from the spark

arrester screen with a wire brush.

5. Replace the spark arrester if it is damaged.

6. Position the spark arrester in the muffler and attach

with the three screws.

Failure to clean the spark arrester will result in degraded

engine performance.

CAUTION

MAINTENANCE AND STORAGE

Federal and local laws and administrative requirements

indicate when and where spark arresters are required.

When ordered, spark arresters are required for operation

of this generator in National Forest lands. In California,

this generator must not be used on any forest- covered

land, brush-covered land, or grass- covered land unless

the engine is equipped with a spark arrester.

NOTE

*To be performed by knowledgeable, experienced owners or

Champion Power Equipment certified dealers.

Generator Maintenance

Make certain that the generator is kept clean and stored

properly. Only operate the unit on a flat, level surface in

a clean, dry operating environment. DO NOT expose the

unit to extreme conditions, excessive dust, dirt, moisture

or corrosive vapors.

Use a damp cloth to clean exterior surfaces of the generator.

Use a soft bristle brush to remove dirt and oil.

Use an air compressor (25 PSI) to clear dirt and debris

from the generator.

Inspect all air vents and cooling slots to ensure that they

are clean and unobstructed.

DO NOT use a garden hose to clean the generator.

Water can enter the generator through the cooling

slots and damage the generator windings.

CAUTION

Every 8 hours or daily

Check oil level

Clean around air intake and muffler

Check hoses for leaks

First 5 hours

Change oil

Every 50 hours or every season

Clean air filter

Change oil if operating under heavy load or in hot

environments

Every 100 hours or every season

Change oil

Clean/Adjust spark plug

Check/Adjust valve clearance*

Clean spark arrester

Clean fuel tank and filter*

Every 250 hours

Clean combustion chamber*

Every 3 years

Replace fuel line and LPG hose