15

ENGLISH

92050-1

OPERATION

HORIZONAL position is used for lighter logs that can

easily be loaded onto the beam.

VERTICAL position is used for light logs as well as

heavy logs that are difficult to load onto the beam.

Back injury can result from lifting logs onto the log

splitter if proper lifting techniques are not used.

NOTE

It is normal for the hydraulic fluid to become foamy

or frothy during operation.

NOTE

Log Splitter Operation

1. ALWAYS wear ear and eye protection, protective clothing

and safety gear.

2. Block tires and put support leg in the DOWN position

to prevent unintended movement of the log splitter

during operation.

3. Set log splitter in either the horizontal or vertical

position.

4. Load a log onto the beam against the end plate (MAX

LOG LENGTH – 60.3 cm {23.8 in.}).

5. Make sure all limbs are clear of crush zones.

6. Push the control valve handle forward (towards the

end plate) to split the log.

7. Push the auto control valve handle backward to

return the wedge to its original position.

8. Clear the split wood from the work zone.

Do not hold auto control valve in return position. It

will damage the stop block or beam.

CAUTION

Operation at High Altitude

The density of air at high altitude is lower than at sea

level. Engine power is reduced as the air mass and

air-fuel ratio decrease. Engine power and output will

be reduced approximately 3

½

% for every 1000 feet of

elevation above sea level. This is a natural trend and

cannot be changed by adjusting the engine. At high

altitudes increased exhaust emissions can also result

due to the increased enrichment of the air fuel ratio.

Other high altitude issues can include hard starting,

increased fuel consumption and spark plug fouling.

To alleviate high altitude issues other than the natural

power loss, Champion Power Equipment can provide a

high altitude carburetor main jet. The alternative main

jet and installation instructions can be obtained by

contacting Customer Support. Installation instructions

are also available in the Technical Bulletin area of the

Champion Power Equipment internet site.

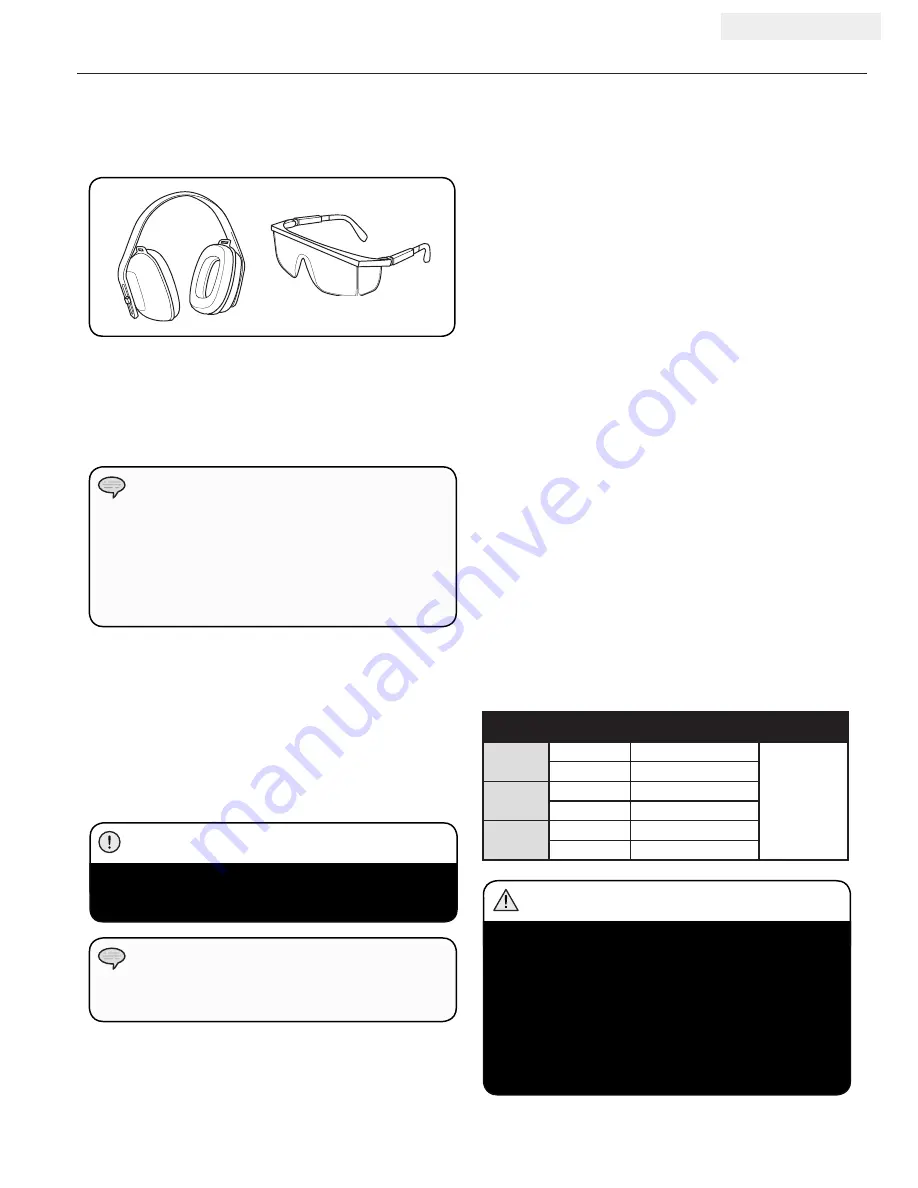

The part number and recommended minimum altitude

for the application of the high altitude carburetor main

jet is listed in the table below.

In order to select the correct high altitude main jet

it is necessary to identify the carburetor model. For

this purpose, a code is stamped on the side of the

carburetor. Select the correct main jet part number

corresponding to the carburetor code found on your

particular carburetor.

Operation using the alternative main jet at

elevations lower than the recommended minimum

altitude can damage the engine. For operation at

lower elevations, the standard main jet must be

used. Operating the engine with the wrong engine

configuration at a given altitude may increase

its emissions and decrease fuel efficiency and

performance.

WARNING

Carburetor

Code

Main Jet

Part Number

Altitude

P19-1-Z

Standard

26.131017.00.Z

3500 Feet

(1067 Meters)

Altitude

26.131017.00.01.Z

P19-1-H

Standard

26.131017.00.H

Altitude

26.131017.00.01.H

P19-1-Y

Standard

26.131017.00.Y

Altitude

26.131017.00.01.Y