22

92251-1

ENGLISH

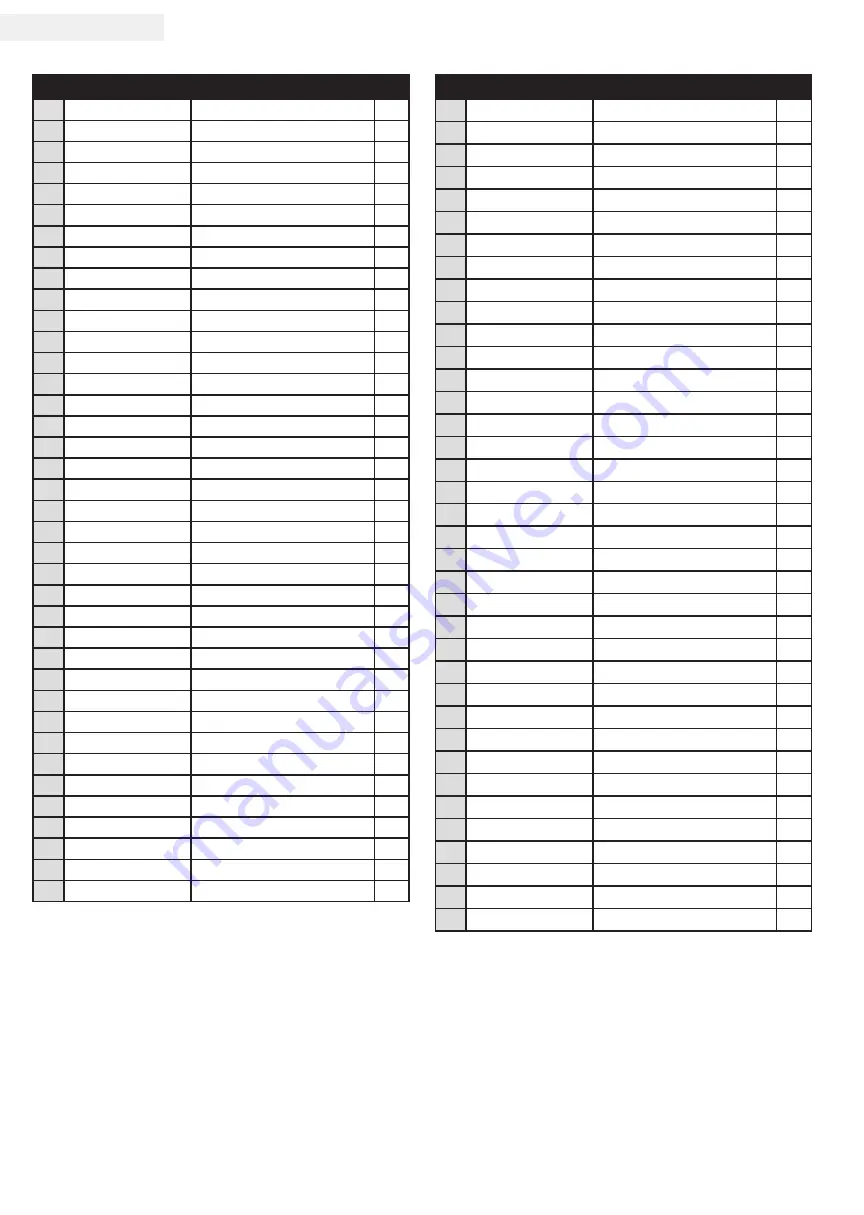

Parts List

# Part number

Description

Qty

1

PMJ22J-02-00

Beam

1

2

GB/T 5782-2000

BOLT M12×75(12.9)

1

3

PMJ22J-04-00

Wedge Slide

1

4

GB/T 95-2000

Washer ø12

7

5

GB/T 889.1-2000

Lock Nut M12

8

6

PMJ22G-51

Control Valve "IN" Connector

1

7

PMJ22J-12

Control Valve

1

8

PMJ22J-19

Plate

1

9

GB/T 818-2000

Bolt M8x12

2

10

GB/T 859-1987

Washer ø8

2

11

PMJ22G-49

Control Valve "OUT" Connector

2

12

JB/T 8870-1999

Clamp d25

2

13

PMJ7-15

Right Angle Joiner

2

14

PMJ7-22

Through Joiner

1

15

PMJ22Q-21

Hydraulic Hose (Valve-Cylinder)

1

16

PMJ22Q-08-00

Cylinder

1

17

PMJ22G-15

Hydraulic Hose (Valve-Oil Tank)

1

18

PMJ22J-06

Base Tube

1

19

PMJ22J-01-00

Base Connector

1

20

PMJ22J-10

Pin

1

21

PMJ22G-30

R Pin

2

22

PMJ22G-40

2 in. Coupler

1

23

GB/T 5782-2000

Bolt M12×80

2

24

GB/T 5782-2000

Bolt M12×90

1

25

GB/T 97.2-1985

Washer ø12

4

26

PMJ22G-41

Safety Chain With Hook

2

27

PMJ22J-07-00

Front Support Leg

1

28

GB/T 5782-2000

Bolt M12×65

2

29

PMJ22J-18

Hydraulic Hose (Valve-Pump)

1

30

GB/T 3452.1-92

"O" Ring ø10×2.65

1

31

PMJ22G-21

Outlet Connector Of Pump

1

32

PMJ22J-14

Gear Pump

1

33

JB/T 8870-1999

Clamp d40

2

34

PMJ22G-17

Oil Pipe

1

35

GB/T 5783-2000

Bolt M8×30

4

36

GB/T 95-2000

Washer ø8

16

37

GB/T 93-1987

Lock Washer ø8

16

38

GB/T 6170-2000

Nut M8

9

# Part number

Description

Qty

39

GB/T 77-2000

Screw M6×10

1

40

PMJ22G-26

Gear Pump Connector

1

41

ASME B18.2.1 1996

Bolt 5/16 in.-24×1 in.

4

42

PMJ22G-29

Engine Bushing

1

43

TC7Q002

Engine

1

44

GB/T 1096-1979

Flat Key 5x5

1

45

PMJ22G-28

Engine Connector

1

46

PMJ22G-27

Gear Pump Stand

1

47

PMJ22G-32

Connector Cover

1

48

GB/T 845C-1985

Tapping Screw

4

49

GB/T 848-1985

Lock Washer ø4

4

50

GB/T 859-1987

Washer 4

4

51

GB/T 1099-1979

Flat Key 3x3

1

52

PMJ22Q-22

Filter Connector

1

53

PMJ22Q-20

Internal Oil Filter

1

54

PMJ22G-19

Oil Plug

1

55

GB/T 5782-2000

Bolt M8×45

4

56

PMJ22J-05-02

Axle Cap

2

57

GB/T 9459-1988

Slotted Nut M20x1.5

2

58

L44634 LYC DS

Tapered Bearing

4

59

PMJ22D-05-03

Wheel

2

60

PMJ22J-05-01

Cased Seal

2

61

GB/T 91-2000

Cotter Pinø 4×32

2

62

PMJ22M-01-00

Oil Tank

1

63

PMJ22G-12

Hinge Pin

1

64

GB/T 5782-2000

Bolt M12×85

2

65

GJY12-3

R Pin

1

66

PMJ22G-18

Screw NPT 1 in.

1

67

GB 1160.2-89

Oil Scale

1

68

PMJ22J-15

Pin

1

69

GB/T 798-1988

Swing Bolt M8x28

1

70

PMJ22G-38

Big Tension Spring

1

71

GB/T 5783-2000

Bolt M8×20

4

72

PMJ22J-03

Cylinder Fixing Plate

2

73

PMJ22G-52

Auto Filter

1

74

PMJ22G-50

Auto Filter Base

1

75

PMJ22Q-23

Through Joint

1