REV 92750-20131216

16

92750

ENGLISH

MAINTENANCE AND STORAGE

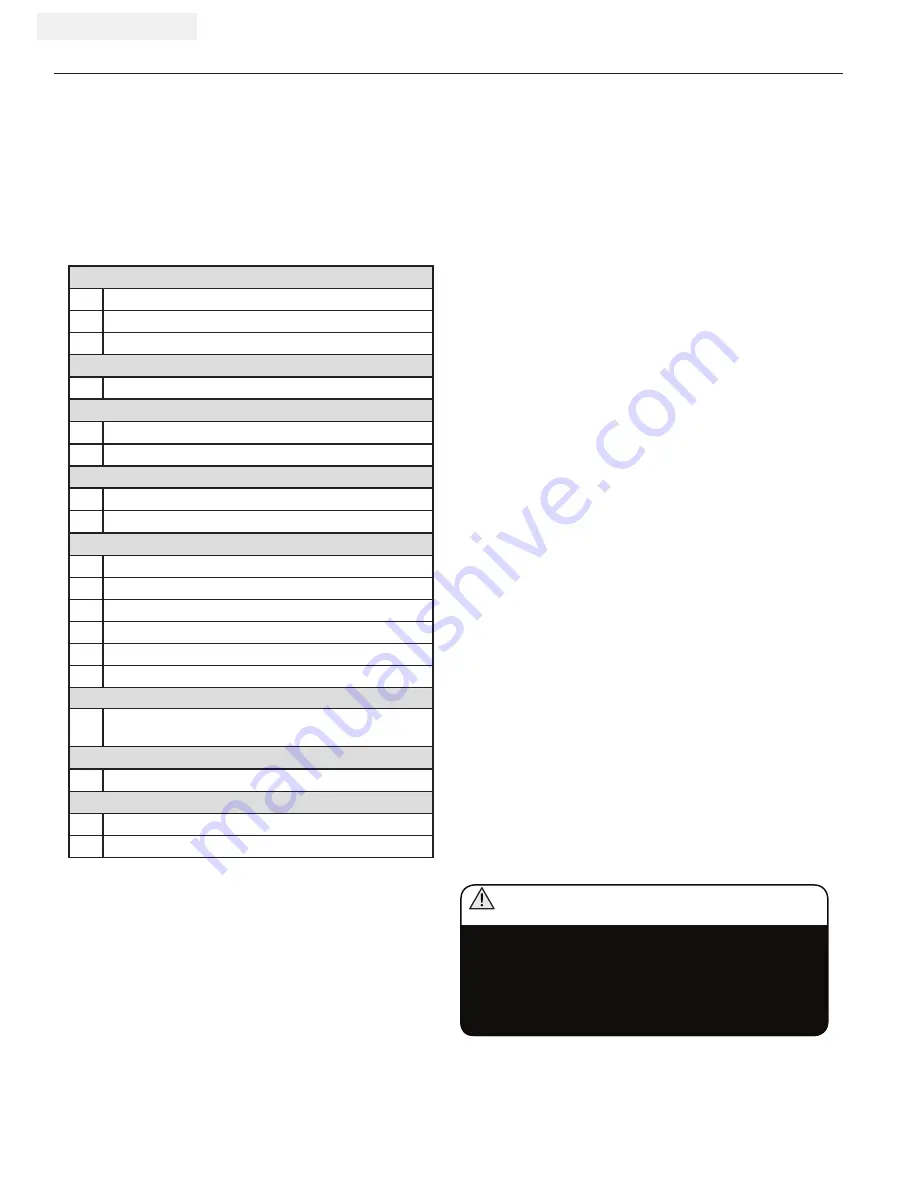

Maintenance Schedule

Follow the service intervals indicated in the schedule

below . Service your log splitter more frequently when

operating in adverse conditions . Contact our help line at

1-877-338-0999 to locate the nearest Champion Power

Equipment authorized service dealer for your log splitter

or engine maintenance needs .

Log Splitter Maintenance

Make certain that the log splitter is kept clean and stored

properly . Only operate the unit on a flat, level surface in

a clean, dry operating environment . DO NOT expose the

unit to extreme conditions, excessive dust, dirt, moisture

or corrosive vapours .

Inspect all air vents and cooling slots to ensure that they

are clean and unobstructed .

Clean spark arrester every 100 hours .

Check and tighten all bolts and nuts before operating the

log splitter .

*To be performed by knowledgeable, experienced owners, any small

engine repair shop, or Champion Power Equipment certified dealers .

Every time of use or daily

Check engine and hydraulic oil levels

Clean around air intake and muffler

Check air filter

First 5 Hours

Change engine oil

Every 25 Hours or per 1 month

Change engine oil

Clean air filter

Every 50 hours or per 6 months

Clean and adjust spark plug

Check cooling fan

Every 100 hours or per 1 year

Clean spark arrester (optional)

Check/adjust maximum load speed*

Check/adjust valve clearance*

Clean fuel tank and filter*

Change hydraulic oil

Change hydraulic oil filter

Every year

Inspect wheel bearings and repack bearing grease

as needed

Every 200 hours

Clean combustion chamber

Every 200 hours or per 2 years

Check/replace fuel line

Change spark plug

Never store the log splitter inside next to appliances where

there is a source of heat or open flame, spark or pilot light

because they can ignite gasoline vapors .

DO NOT store a log splitter near fertilizer or any corrosive

material .

Even with an empty gas tank, gasoline vapors could ignite .

WARNING

Storage

Refer to the Maintenance section for proper cleaning

instructions .

Log Splitter Storage

1 . The log splitter needs to be cool for at least 5

minutes before storing .

2 . Clean the log splitter before storage according to the

Maintenance section .

3 . Retract the wedge to protect the rod from corrosion .

4 . Wipe the beam and wedge with an oily rag to prevent

rust and corrosion .

Engine Stored for Less than 30 Days

1 . Allow the engine to cool completely before storage .

2 . Clean engine according to the Maintenance section .

3 . To extend the fuel storage life add a properly

formulated fuel stabilizer to the tank .

4 . Ensure the fuel valve is in the “OFF” position .

Engines Stored for Over 30 Days

1 . Add a properly formulated fuel stabilizer to the tank .

2 . Run the engine for a few minutes so the treated fuel

cycles through the fuel system and carburetor .

3 . Turn the fuel valve to the “Off” position .

4 . Let the engine run until fuel starvation has stopped

the engine . This usually takes a few minutes .

5 . The engine needs to cool completely before cleaning

and storage .

6 . Clean the engine according to the maintenance section .

7 . Change the oil .

8 . Remove the spark plug and pour about 1⁄2 ounce

(14 .8 mL) of oil into the cylinder . Using the Recoil,

crank the engine slowly to distribute the oil and

lubricate the cylinder .

9 . Reattach the spark plug .