19

REV 92750-20131216

ENGLISH

92750

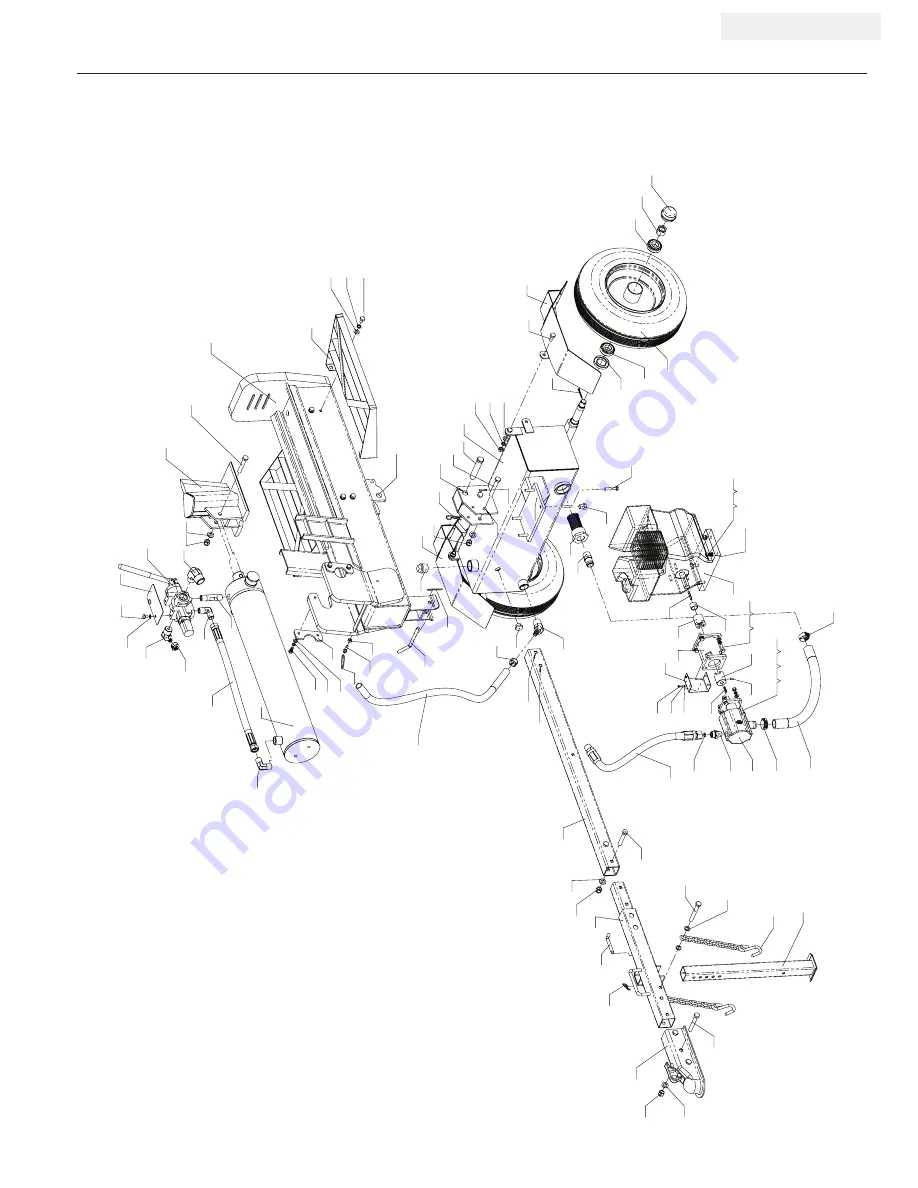

Parts Diagram

SPECIFICATIONS

1

3

2

4

63

16

15

5

13

6

11

12

7

68

51

50

21

66

17

4

5

28

19

24

20

21

26

27

23

22

5

25

30

31

32

33

34

33

47

48

46

42

44

43

40

39

49

52

54

12

11

64

59

58

60

58

57

56

61

18

62

5

TO(A)

(A)

TO(B)

TO(C)

TO(D)

(B)

(C)

(D)

65

55

4

TO(E)

(E)

Parts Diagram

TO(F)

(F)

41

37

36

35

36

37

38

38

37

36

71

36

37

72

9

70

69

38

67

10

8

13

29

53

14

73

74

75

76

45

77

78

79

74

75

80

142

PMJ22J-11-03

引擎固定管

1

焊接钢管

0.68

141

PMJ22G-01-02

油箱封板

2

Q235

1.05

140

PMJ22Q-11-01

油箱

1

焊接钢管

12.90

139

1

138

PMJ22H-11-02

加强板

1

Q235

0.11

137

PMJ22H-11-01

连接块

2

Q235

0.68

136

PMJ22J-20

刀头螺栓

1

30CrMo

83.2151

135

GB/T 5781-2000

C级全螺纹六角头螺栓

M10×25

4

35

0.03

134

GB/T 12618-90

抽芯铆钉 4×8

8

133

GB/T 6170-2000

1型六角螺母 M10

4

0.01

132

PMJ22G-37

尾灯

2

示意图

0.00

131

PMJ22G-36

尾灯座

2

Q235

0.26

130

PMJ22G-35-01

左挡泥板

1

Q235

1.34

129

PMJ22G-34-03

长连接板

2

Q235

0.22

128

PMJ22G-34-02

短连接板

2

Q235

0.06

127

PMJ22G-34-01

右挡泥板

1

Q235

1.34

126

1

125

1

124

1

123

GB/T 6184-2000

1型全金属六角锁紧螺母

M30

1

122

GB/T 3452.1-92

O形橡胶密封圈

112×5.3

1

121

GB/T 3452.1-92

O形橡胶密封圈

118×2.65

1

120

GB/T 3452.1-92

O形橡胶密封圈

103×5.3

1

119

PMJ30-08-05

导向环

1

碳纤维+酚醛树脂复

合材

118

152071-07

内支承圈

2

117

PMJ30-08-08

U型密封圈45X55X7

1

聚氨脂

0.01

116

DH45

防尘圈45X53X5X6.5

1

聚氨脂

0.00

115

PMJ30-08-06

密封圈Φ120

1

聚氨脂(海翠)

114

GB 3452.1-92

O形橡胶密封圈

45×3.55

1

橡胶Ⅰ- 2

2.26

113

PMJ30-08-04

底座

1

45

4.28

112

PMJ30-08-03

活塞头

1

QT450-10

2.48

111

PMJ30-08-02

活塞杆

1

40Cr

9.10

110

PMJ30-08-01-04

油缸转轴

2

45

0.61

109

PMJ30-08-01-03

顶帽

1

20

5.88

108

PMJ30-08-01-02

油缸

1

20/精拉钢管

12.52

107

PMJ30-03

油缸固定块

2

Q235

0.14

106

PMJ27-02-11

挡板

1

Q235

0.14

105

PMJ27-02-02Z

档块

1

Q235

5.73

104

PMJ27-02-02Y

档块

1

Q235

5.73

103

PMJ22H-02-07

U形架

1

Q235

18.30

102

PMJ22G-01-11

挡泥板固定块

4

Q235

0.07

101

PMJ22Q-11-02

过滤器安装座

1

Q235

0.12

100

PMJ22G-01-04

引擎固定板

1

Q235

1.71

99

PMJ22G-01-07

放油接头

1

Q235

0.03

98

PMJ22G-01-08

加油接头

1

Q235

0.14

97

PMJ20J-01-09

回油接头

1

45

0.09

96

PMJ22J-11-02

轮轴

2

35

1.66

95

PMJ22J-02-05

连接块

2

Q235

0.37

94

PMJ22J-02-04-01

挡块

1

Q235

1.24

93

PMJ22J-02-04-02

加强板

4

Q235

0.05

92

PMJ22J-02-03-01

固定件

1

Q235

0.68

91

PMJ22J-02-03-02

垫块

1

Q235

0.12

90

PMJ22J-02-08-01

挡块

1

Q235

1.24

89

PMJ22J-02-06

挡块焊条

3

Q235

0.02

88

PMJ22J-02-01-01

工作面板

1

Q235

11.07

87

PMJ22J-02-01-02

方钢

2

Q235

0.71

86

PMJ22J-02-10

盖板

1

Q235

1.02

85

PMJ22J-04-01

刀架底板

1

Q235

3.49

84

PMJ22G-04-03

加强板

2

Q235

0.94

83

PMJ22G-04-04

上封板

1

Q235

0.24

82

PMJ22J-04-03

活塞杆固定块

2

Q235

0.38

81

PMJ22J-04-04

垫块

2

Q235

0.12

80

PMJ22G-28

发动机联轴器

1

铁基粉末冶金

0.20

79

PMJ22J-01-01

连接管

1

Q235

0.46

78

PMJ22J-01-03

连接管

1

Q235焊接钢管

0.93

77

PMJ22J-08-01-05

拉手

2

Q235A

0.12

76

PMJ22J-07-02

脚垫

1

Q235

0.13

75

PMJ22G-08-01-05

前螺套

1

Q235

0.11

74

GB/T 3452.1-92

O形橡胶密封圈

31.5×3.55

1

橡胶Ⅰ- 3

73

PMJ30F-01-01

右侧板

2

Q235

0.29

72

PMJ22F-01-03

中间连接板

8

Q235

0.25

71

PMJ30F-01-03

加强板

4

Q235

0.16

70

G 1/2-60

G 1/2油缸接头

2

35

0.22

69

油管扣压式接头 M22

油管扣压式接头 M22

1

示意图

0.03

68

NPT3/4 接头

NPT3/4 接头

1

示意图

0.00

67

GB/T 5781-2000

C级全螺纹六角头螺栓

M10×15

8

材质 <未指定>

2.5936

66

GB/T 93-1987

标准型弹簧垫圈 10

12

65Mn

65

GB/T 95-2000

C级平垫圈 10

12

钢

64

PMJ30F-01-02

左侧板

2

Q235

0.29

63

GB/T 5783-2000

全螺纹六角头螺栓

M8×20

4

62

PMJ22G-38

大拉簧圈

1

65Mn

0.01

61

GB/T 798-1988

活节螺栓 M8×28

1

60

PMJ22J-15

插杆

1

Q235

0.09

59

GB 1160.2-89

旋入式六角型油标 A

M20×1.5

1

58

PMJ22G-18

油箱塞

1

Q235

0.17

57

GJY12-3

钢丝挡圈

1

碳素弹簧钢丝

56

GB/T 5782-2000

六角头螺栓 M12×85

2

55

PMJ22G-12

机架连接轴

1

45

0.26

54

GB/T 91-2000

开口销 4×32

2

53

PMJ22J-05-01

防尘圈

2

示意图

0.00

52

PMJ22J-05-03

轮胎总成

2

示意图

0.01

51

L44634 LYC DS

英制圆锥滚子轴承L4463

4

4

材质 <未指定>

18.06

50

GB/T 9459-1988

A和B级细牙六角开槽薄

螺母 M20×1.5

2

材质 <未指定>

8.40

49

PMJ22J-05-02

轮轴盖

2

示意图

0.00

48

GB/T 5782-2000

六角头螺栓

M8×45(8.8级)

4

材质 <未指定>

3.0280

47

PMJ22G-19

放油塞

1

Q235

0.04

46

PMJ22Q-20

过滤器

1

组合件

0.37

45

PMJ22Q-22

出油接头

1

Q235

0.10

44

GB/T 1096-1979

A型普通平键 3×3

1

材质 <未指定>

0.22

43

GB/T 848-1985

A级小垫圈 4

4

材质 <未指定>

0.02

42

GB/T 859-1987

轻型弹簧垫圈 4

4

41

GB/T 818-2000

十字槽盘头螺钉 M4×10

4

材质 <未指定>

0.24

40

PMJ22G-32

连接套筒盖

1

Q235

0.10

39

PMJ22G-27

连接套筒

1

ZL101A

0.39

38

GB/T 1096-1979

C型普通平键 5×36

1

37

PMJ22G-48

发动机

1

组合件

102.75

客户提供

36

PMJ22G-29

发动机衬套

1

Q235

0.02

35

ASME B18.2.1 1996

全螺纹六角头螺栓

5/16"-24×1"

4

34

PMJ22G-26

泵联轴器

1

铁基粉末冶金

0.24

33

GB/T 77-2000

内六角平端紧定螺钉

M6×10

1

32

GB/T 6170-2000

螺母 M8

9

31

GB/T 93-1987

标准型弹簧垫圈 8

16

65Mn

0.00

30

GB/T 95-2000

C级平垫圈 8

16

钢

29

GB/T 5783-2000

全螺纹六角头螺栓

M8×30

4

28

JB/T 8870-1999

喉箍 d32

2

27

PMJ22J-14

齿轮泵

1

示意图

0.00

26

PMJ22G-21

泵输出接头

1

Q235

0.10

25

GB/T 3452.1-92

O型密封圈 10×2.65

1

橡胶Ⅰ- 3

0.00

24

GB/T 5782-2000

六角头螺栓

M12×65(8.8级)

2

材质 <未指定>

9.4367

23

PMJ22J-07-01

支撑脚

1

Q235焊接钢管

1.41

22

PMJ22G-41

安全链钩

2

示意图

0.00

21

GB/T 848-2002

A级小垫圈 12

4

20

GB/T 5782-2000

六角头螺栓 M12×90

1

19

GB/T 5782-2000

六角头螺栓 M12×80

2

钢

18

PMJ22G-40

拖车连接器

1

示意图

0.00

17

PMJ22G-30

钢丝挡圈

2

碳素弹簧钢丝

0.01

16

PMJ22J-10

插杆

1

Q235

0.07

15

PMJ22J-01-02

底脚接管

1

Q235焊接钢管

1.48

14

PMJ22J-06

底架管

1

Q235焊接钢管

4.97

13

PMJ7-22

直通接头

1

45

0.15

12

PMJ7-15

直角接头

2

35

0.13

11

JB/T 8870-1999

喉箍 d25

2

10

PMJ22G-49

滤清器接头

2

35

0.23

9

GB/T 859-1987

轻型弹簧垫圈 8

2

8

GB/T 818-2000

十字槽盘头螺钉 M8×12

2

7

PMJ22J-19

阀标贴板

1

Q235

0.12

6

PMJ22J-12

控制阀

1

示意图

0.00

5

PMJ22G-51

NPT3/4直角内外接头

1

35

0.43

4

GB/T 889.1-2000

1型非金属嵌件六角锁紧

螺母 M12

8

3

GB/T 95-2000

C级平垫圈 12

7

2

PMJ22J-04-02

刀片

1

40Cr

3.52

1

PMJ22J-02-09

前挡板

1

Q345

19.62

序

号

代 号

名 称

数

量

材 料

重 量

备 注