REV 93520-20130425

8

93520

ENGLISH

ASSEMBLy

Your log splitter requires some assembly.

If you have any questions regarding the assembly of your

log splitter, call our help line at 1-877-338-0999. Please

have your serial number and model number available.

Open Shipping Crate

1. Set the shipping crate on a solid, flat surface

2. Carefully cut the shipping bands and remove lid of

shipping crate.

3. Locate all hardware before beginning assembly.

1) Install the Hydraulic Oil Filter

Install the oil filter base onto the hydraulic oil tank.

The barb fitting should be oriented vertically and once

installed the oil filter should be oriented so that it does

not extend below the hydraulic oil tank.

2) Install the Fenders

1. Attach the fender to the side of the hydraulic oil tank

with an M10x30 bolt, M10 washer, M10 lock washer

and M10 nut. The safety reflector should be facing the

back of the hydraulic oil tank.

2. Repeat with second fender on opposite side.

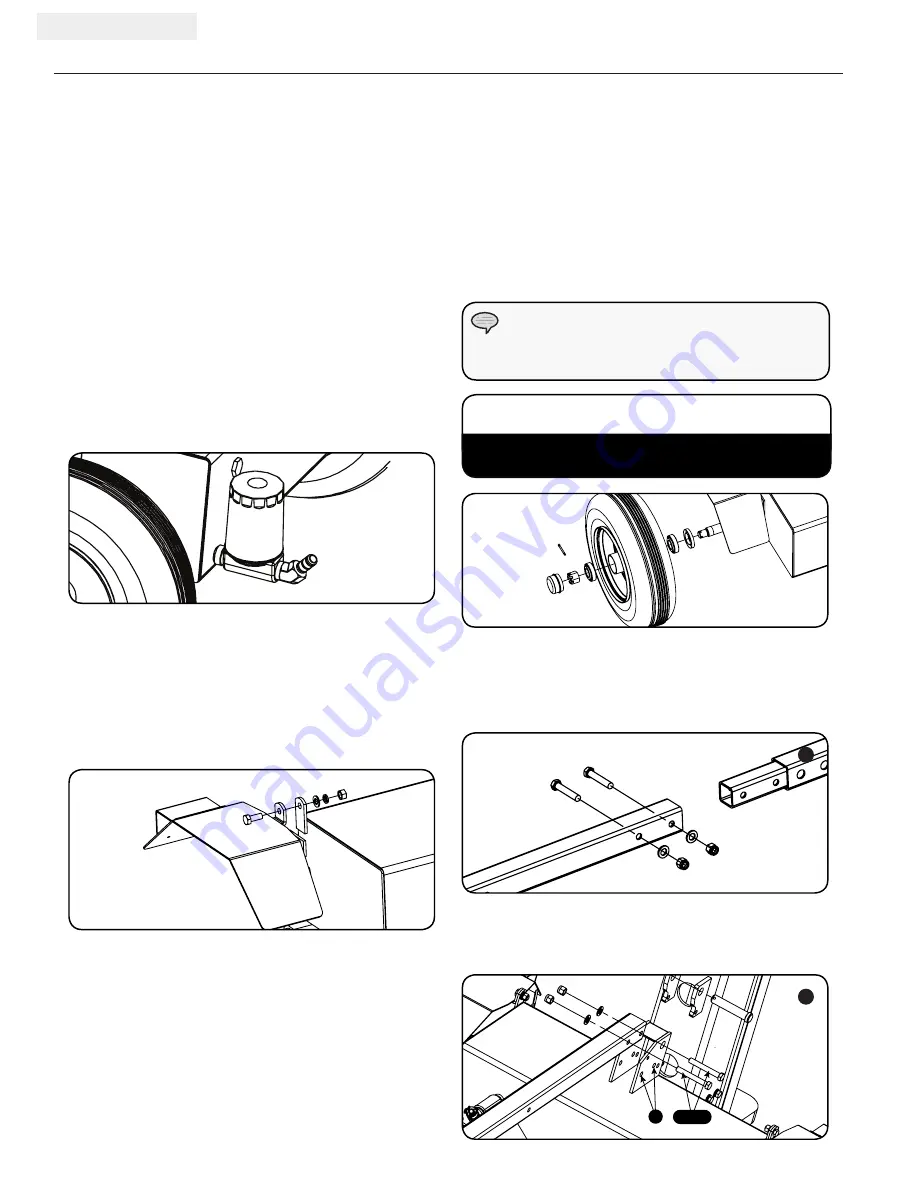

3) Install the Wheels Cont’d.

3) Install the Wheels

1. Place bearings in the wheel hub and orient the bearing

so that the taper on the bearing matches the taper on

the hub.

2. Press the bearing seal flush into the hub. Use a

hammer and wood block to flush the seal with the end

of the hub.

3. Slide the wheel over the axel on the hydraulic oil tank.

4. Install the castle nut and tighten by hand. Tighten

another ¼ turn with a wrench to seat the bearing.

5. Spin the wheel to distribute grease.

6. Loosen the castle nut and re-tighten by hand.

7. Install the cotter pin through the castle nut and axle

and spread the ends of the pin to prevent the nut from

backing off.

8. Place axle cap over castle nut and axle. Use a hammer

and wood block to seat the cap.

9. Repeat steps 1-8 for the other wheel.

Keep the wheel hub clean and free from debris during

assembly.

NOTE

Over-tightening the castle nut will cause the bearings to

run hot and fail prematurely.

CAUTION

4) Install the Tow Bar

1. Assemble two piece tow bar with two M12x65 bolts

and M12 lock nuts and washers. (A)

A

A

To

A

B

2. Attach the tow bar to the bracket on top of the hydraulic

oil tank with two M12x85 bolts and M12 lock nuts. (B)

Tighten to 50 ft-lb.