20

ENGLISH

RT10010

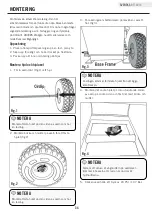

6. The screws may be tight due to corrosion and

dirt buildup. Ensure that the supplied hex key (17)

is a good fit onto the screw and that the hex key

(17) is held firmly and at right angles to the blade.

Remove the four blade securing screws by rotating

the hex key (17) in the anti- clockwise direction. (fig.

34).

1. Stop the engine.

2. Remove the belt cover by removing the six bolts with

M10 spanner.

7. To remove the second blade repeat steps 5 and 6.

8. Once the blades are replaced refit blade shaft cover

(14) and hopper (4).

Fig.34

Fig.35

Fig.36

Ensure the blade securing screws secure the

blades are fully tightened prior to operation. If

there is any vibration or abnormal noise after

re-starting the wood chipper, immediately stop

operation. Check that the blades are assembled

correctly and securely tightened.

WARNING

It is recommended to add Loctite¨ 222 Threadlocker to

the thread of the blade securing screws, Loctite¨ 222

Threadlocker is available from all Bunnings stores. This

assists in securing the screw and reduces the chance

of the blade securing screw vibrating loose whilst in

operation.

NOTE

Drive Belt (fig. 35-39)

If the drive belt is damaged, it should be replaced.

Ensure that the drive belt tension is maintained at

all times. If worn, slipping may occur (this is usually

noticeable by a squealing noise) or slowing and or

stopping of the blades when the machine is under load.

3. Loosen, do not remove the four engine

mounting bolts (A) (two on the front and two on the

rear side of the engine.

4. Loosen, do not remove the two engine locating

bolts (B), one either side of the engine. Depending

on the direction you need to move the engine,

you can either increase or degrease the drive belt

tension. By rotating these two bolts sufficiently you

can slide the engine either forward or backward.

MaIntenance