13-11-614 Page 49

LUBRICANT MAINTENANCE INTERVAL

- The recommended oil change interval is 2000 hours or one

year, whichever comes first, based on normal operating conditions. The refill capacity of the oil system is

8 gallons (30 liters).

NOTICE

IF OIL IS ANALYZED at the end of a maintenance interval (2000 hr. max.), and is

found in good condition, it may be used for the next 2000 hour interval – GD

provides free oil analysis services. OTHERWISE, IF OIL IS NOT ANALYZED at

the end of any interval, it must be changed.

Severe operating conditions (e.g., high humidity, long idle periods, etc.) may require shorter oil change

intervals. It is essential that a lubricant analysis program be followed to help define the oil change

intervals and protect the compressor against damage by contaminated lubricant.

Oil Filter Maintenance Interval

- The oil filter element should be replaced when the oil is changed. The

screw-on type cartridge must be set firmly against the filter head (approximate 1/4 turn after making

contact) to avoid oil leaks.

Oil Breather (Gear Box)

- The breather element should be cleaned whenever the oil is changed. To

service, unscrew the wing nut and remove the element. Cleanse the element in solvent and dry

completely before reassembling.

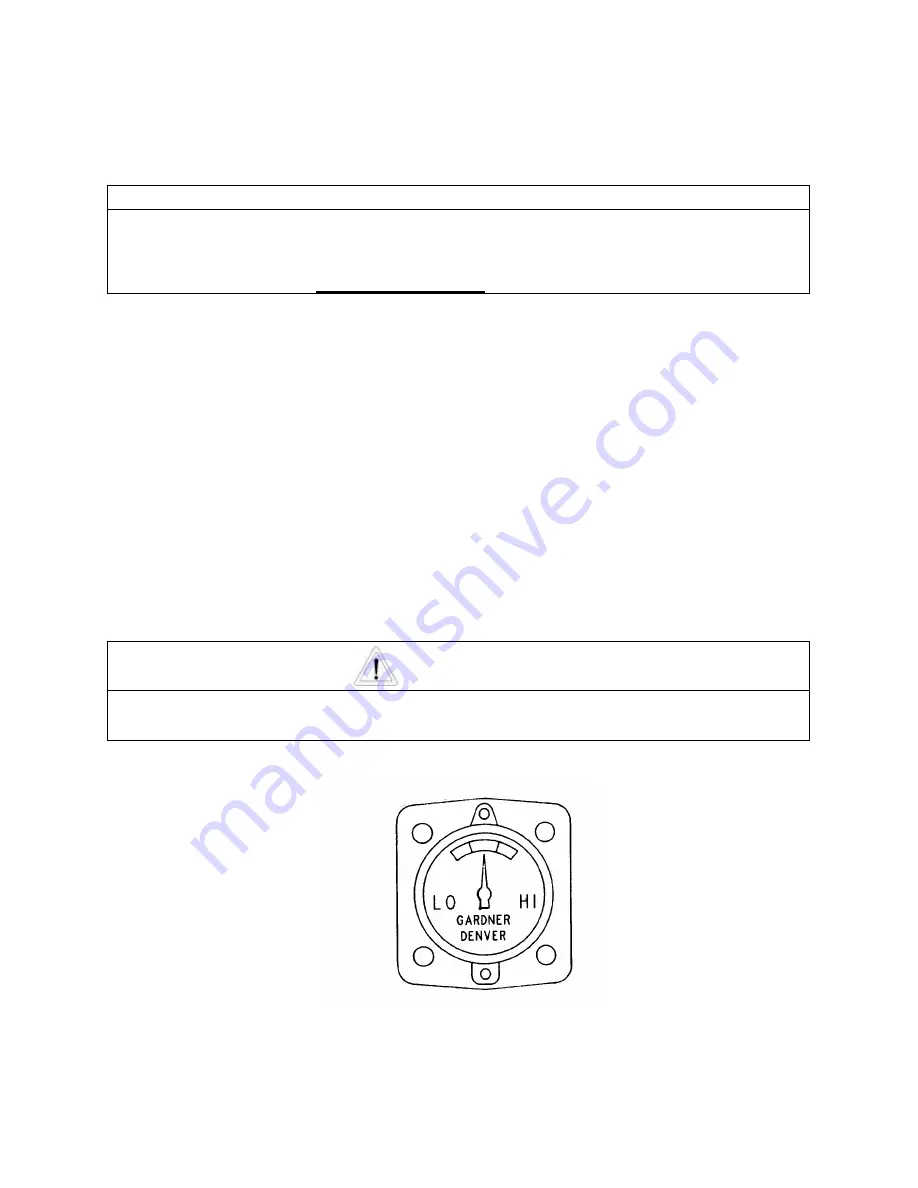

Oil Level Gauge

(Figure 5-1) - The gauge pointer indicates the oil level in the sump.

•

Green Zone: Adequate oil level.

•

Red Zone: Insufficient oil, but wait until the pointer reaches the bottom of the zone to add oil.

•

Yellow Zone: Excessive oil level. Drain oil to correct.

CAUTION

The oil level gauge indicates accurate oil levels when the compressor is in

operation. Make sure to check for proper oil level with the compressor running.

Figure 5-1 – OIL LEVEL GAUGE

Summary of Contents for ROTORCHAMP EWF99C-100

Page 7: ...13 11 614 Page 7 Figure 1 2 PACKAGE ILLUSTRATION AIR COOLED 309EWF797 A Ref Drawing ...

Page 8: ...13 11 614 Page 8 Figure 1 3 PACKAGE ILLUSTRATION WATER COOLED 310EWF797 A Ref Drawing ...

Page 9: ...13 11 614 Page 9 Figure 1 4 AIR COOLED SCHEMATIC 307EWF797 A Ref Drawing ...

Page 10: ...13 11 614 Page 10 Figure 1 5 WATER COOLED SCHEMATIC 308EWF797 A Ref Drawing ...

Page 29: ...13 11 614 Page 29 Figure 4 2 FLOW CHART FOR SETUP PROGRAMMING 300EWC1255 Ref Drawing ...

Page 43: ...13 11 614 Page 43 303EWF546 A Ref Drawing Page 2 of 2 ...

Page 45: ...13 11 614 Page 45 304EWF546 A Ref Drawing Page 2 of 2 ...

Page 47: ...13 11 614 Page 47 305EWF546 A Ref Drawing Page 2 of 2 ...