13- 11- 605

Page 43

2.

Pressure drop through a filter with a freshly

cleaned element is below three (3) inches (76

mm) of water with the compressor running at full

load -- this would indicate a rupture or crack.

Inlet Tube

-- Inspect the inlet screen and tube for dirt

accumulation each time the filter is serviced. Clean the

tube when required by ramming a clean dry cloth

through the tube. Wipe the inside of the filter body to

remove any dirt falling from the inlet tube before rein-

stalling the element.

Causes of short element life include: severe dust

conditions, infrequent servicing, improper cleaning, or

contamination by oil or chemical fumes.

Summary of Contents for ROTORCHAMP RCOF20

Page 13: ...13 11 605 Page 4 FIGURE 1 6 AIR WATER SCHEMATIC 300EWC797 B Ref Drawing ...

Page 16: ...13 11 605 Page 7 DECALS 206EAQ077 300EWC077 301EWC077 211EAQ077 207EAQ077 ...

Page 17: ...13 11 605 Page 8 DECALS 216EAQ077 206EWD077 222EAQ077 221EAQ077 208EAQ077 ...

Page 31: ...13 11 605 Page 22 FIGURE 4 2 FLOW CHART FOR SET UP PROGRAMMING 300EWC1255 Ref Drawing ...

Page 41: ...13 11 605 Page 32 FIGURE 4 6 CONTROL TUBING SCHEMATIC 300EWC797 B Ref Drawing ...

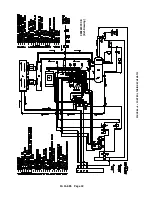

Page 45: ...13 11 605 Page 36 FIGURE 4 10 WIRING DIAGRAM FULL VOLTAGE 301EWC546 A Ref Drawing ...

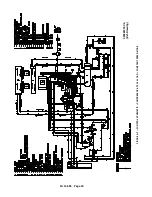

Page 46: ...13 11 605 Page 37 FIGURE 4 11 WIRING DIAGRAM WYE DELTA 302EWC546 A Ref Drawing ...

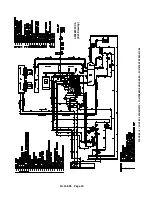

Page 47: ...13 11 605 Page 38 FIGURE 4 12 AUTO SENTRY W CONTROLLER DISPLAY ...

Page 49: ...13 11 605 Page 40 FIGURE 5 1 OIL LEVEL SIGHT GLASS 306EWC797 A Ref Drawing ...

Page 50: ...13 11 605 Page 41 FIGURE 5 2 FLOW DIAGRAM AIR COOLED 300EWC797 A Ref Drawing ...