13- 11- 605

Page 53

Symptom

Recommended action

Compressor runs, but

In the CONSTANT RUN and LOW DEMAND modes, the compressor will

does not load.

not load until the pressure drops below load pressure. Refer to the operat-

ing instructions for further information. If pressure is below the load pres-

sure, check that the inlet valve operates freely. Check that the unloader

valve is wired and operating properly.

Compressor runs,

If the inlet valve closes at low pressure, check the wiring to the blowdown

unloads at low pressure

valve and the piping and check valves in its discharge line.

Compressor does not

The W controller operates the inlet valve to maintain pressure near the

unload.

unload pressure, matching delivery to demand. If the pressure contin-

ues to rise above unload pressure, check that the inlet valve operates free-

ly, and that control air is supplied to the unloader solenoid valve. If nor-

mal unload control does not close the valve, it will be closed during a

blowdown as pressure approaches the high pressure limit.

Compressor cycles rapidly

The external air receiver should be sized appropriately to prevent rapid

between load and unload.

cycles. The rapid response time in the CONSTANT RUN mode will oper--

ate with small receivers, but any plant air system will operate more effi-

ciently with adequately sized storage. Refer to the operating instructions

for further information.

Display is illegible.

The LCD contrast is adjustable from all black to all green. To adjust, find

the small adjustment screw located on the larger circuit board behind the

keypad. Using a small screwdriver, adjust for the most pleasing display.

Erratic pressures

The sequencing system transmits low-- level signal between units to com-

in SEQUENCE only

municate pressures. Units must be properly grounded to a good ground

system, the communications cable should use only appropriate quality

cable, and the cable should be run in its own conduit.

Compressor cycles rapidly

In the sequence mode, the operating system requires all compressors be

in SEQUENCE mode only

piped directly to receiver, such that all transducers sense the same pres-

sure. Check valves or restrictions between compressors and the storage

will cause system instability. Run units in AUTOMATIC mode until the sys-

tem is corrected.

Pressure display error.

Accuracy of the pressure display and controls requires that the controller

and transducers be calibrated together. This MUST be done with no pres-

sure at the transducer, or errors will occur. This is easiest to check with

all pressure removed. All pressure displays should indicate 0 psi (0 bar)

+1 psi. If the display indicates greater pressures, recalibrate the system

as instructed in the configuration adjustments. Note: reservoir pressure

may drop below zero psig when the compressor is stopped, but will return

slowly to zero as the vacuum is relieved.

Summary of Contents for ROTORCHAMP RCOF20

Page 13: ...13 11 605 Page 4 FIGURE 1 6 AIR WATER SCHEMATIC 300EWC797 B Ref Drawing ...

Page 16: ...13 11 605 Page 7 DECALS 206EAQ077 300EWC077 301EWC077 211EAQ077 207EAQ077 ...

Page 17: ...13 11 605 Page 8 DECALS 216EAQ077 206EWD077 222EAQ077 221EAQ077 208EAQ077 ...

Page 31: ...13 11 605 Page 22 FIGURE 4 2 FLOW CHART FOR SET UP PROGRAMMING 300EWC1255 Ref Drawing ...

Page 41: ...13 11 605 Page 32 FIGURE 4 6 CONTROL TUBING SCHEMATIC 300EWC797 B Ref Drawing ...

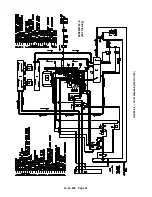

Page 45: ...13 11 605 Page 36 FIGURE 4 10 WIRING DIAGRAM FULL VOLTAGE 301EWC546 A Ref Drawing ...

Page 46: ...13 11 605 Page 37 FIGURE 4 11 WIRING DIAGRAM WYE DELTA 302EWC546 A Ref Drawing ...

Page 47: ...13 11 605 Page 38 FIGURE 4 12 AUTO SENTRY W CONTROLLER DISPLAY ...

Page 49: ...13 11 605 Page 40 FIGURE 5 1 OIL LEVEL SIGHT GLASS 306EWC797 A Ref Drawing ...

Page 50: ...13 11 605 Page 41 FIGURE 5 2 FLOW DIAGRAM AIR COOLED 300EWC797 A Ref Drawing ...