CQF3535

May ‘19

- 15 -

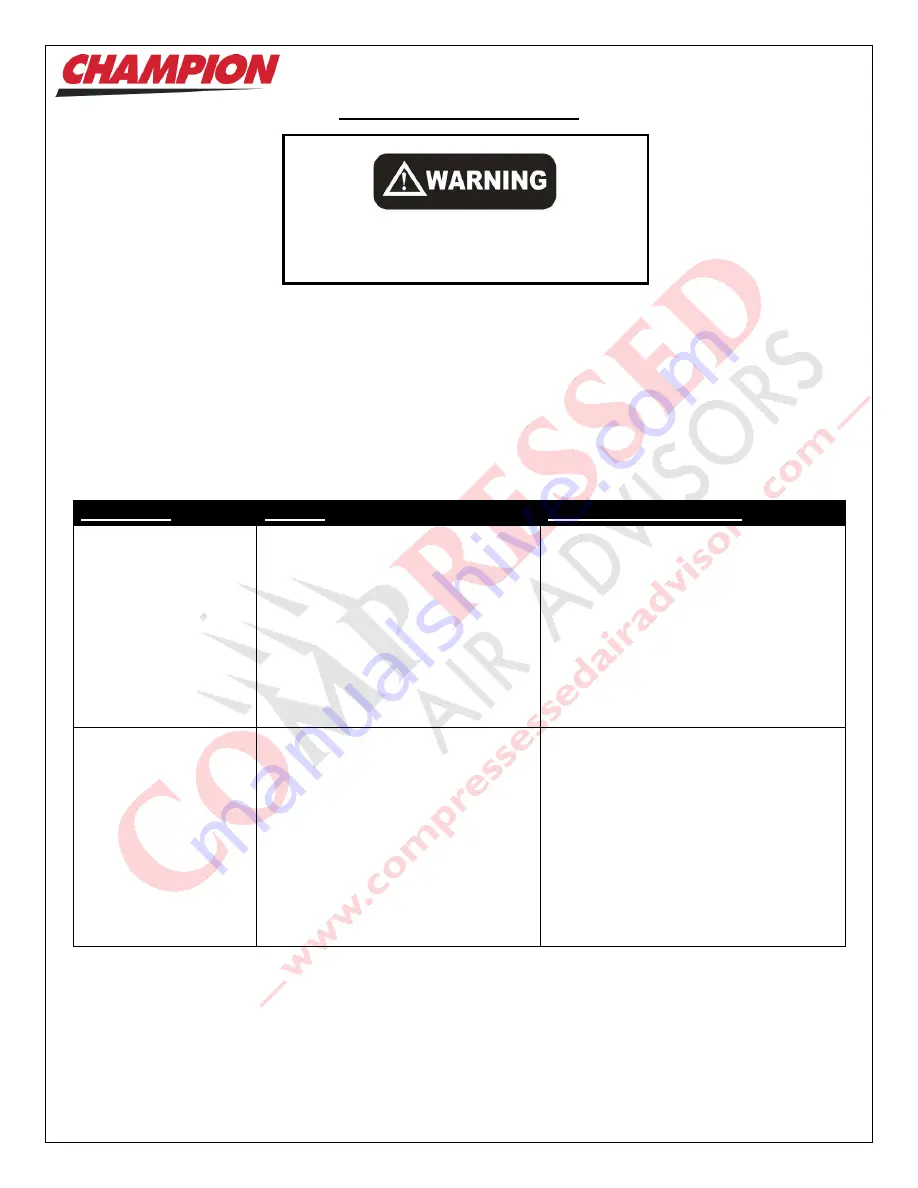

Trouble Shooting Guide

The ‘Conditions’, ‘Causes’, and ‘Suggested Corrections’ as indicated below and on the following page(s) are only

a guideline for failures that we have found to be most common.

Though this information is provided in this booklet, it is assumed and expected that any personnel involved in the

servicing of an Air Compressor Unit is knowledgeable with this type of equipment. Do not attempt to service a

Compressor Unit unless you are familiar with it, as there are many issues that may come into play, the most

important being personal safety and the welfare of the Unit.

Should you have any questions, or require servicing to your Unit, please contact your local Champion Distributor.

Condition:

Cause:

Suggested Correction:

A. Unit won’t start.

No power to the Unit.

Loose and/or missing wires in the electrical

circuit.

Starter Overload is tripped.

Pressure may not be low enough in the

Tank to allow the Unit to start.

Check that power at the disconnect or breaker

is on. Also, check any fuses.

Check that all wiring connections are tight.

With a wiring schematic, check that all wiring is

present and correct.

Reset the overload in the Magnetic Starter.

Drop pressure below the Pressure Switch ‘cut-

in’ pressure.

B. No or Insufficient Air

Flow.

Air Filter is dirty.

Loose Belts.

Pump Valves, Aftercooler, or Tank Check

Valve leaking, sticking, or plugged.

Air leaks at Compressor in in piping system.

Unit is too small for the compressed air

requirements.

Replace the Air Filter.

Tighten as required. Do not over-tighten.

Clean or replace.

Fix leaks. Soap/water mixture will assist in

finding small leaks.

Contact your Champion Distributor for

assistance.

When servicing the Air Compressor, shut off all

power to the Unit, and drain it of air pressure.