CQF3535

May ‘19

- 6 -

Never clamp or bolt Air Receiver Feet to the

floor or support structure. Doing so can

greatly increase stress on the Tank, causing

it to weaken and/or fracture.

To reduce the risk of electric shock or injury,

use indoors only.

The Compressor must not be operated in a

confined area where the heat from the Unit

cannot readily escape.

Installation – Mechanical

Location of the Unit.

Champion

Installation Kit

‘VP’ Compressor

Horsepower

IK515

5 to 15 HP

Items to consider when installing the Unit are as

follows:

The Unit should be located in a dry, clean, cool,

dust free, and well ventilated area. If possible, the

Compressor should be located in a separate

room or area, away from the general operations

of the shop.

Allow a minimum of 18” around and 24” above

the Unit, this being for both the proper ventilation

of the Unit and ease of servicing.

If installing the Unit on a mezzanine, ensure

that the structure can safely support the weight

of the Unit. The Vibration Pads will help to

lessen the sound level of the Unit caused by

harmonics created by the structure.

All Compressor Units must be anchored and

installed as shown below. Failure to do this will

affect the Tank Warranty.

Ensure that the floor under the Unit is smooth,

level and capable of bearing the weight of the

Compressor. The Compressor must sit squarely

on the floor.

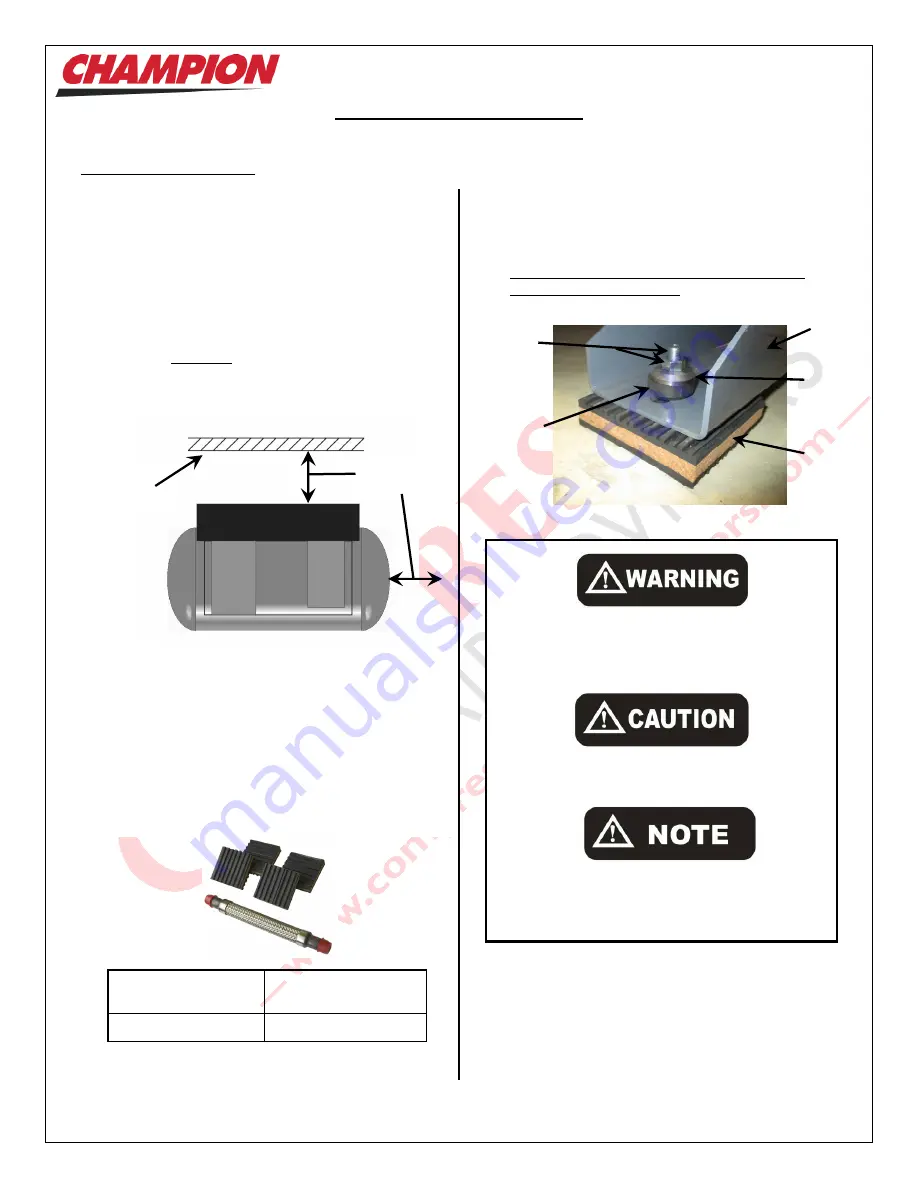

This unit must be anchored to the floor as

indicated at above-right. Champion has available

Installation Kits which include (4) Vibration

Isolator Pads, (1) Stainless Steel Flex Hose, and

Steel and Rubber Washers.

Building

Wall, etc

18” (0.5 m)

minimum

Beltguard

Compressor

(& Opposite)

Anchor c/w

Hex Nut

(By

Installer)

½” Rubber

Washer

(SS-1536)

Compressor

Foot

½” Steel

Washer

(SS-1535)

Isolator

Pad

(UDH-9700)

Floor

If installed in a compressor room, ensure that the

room is adequately ventilated. (One Horsepower

produces approximately 2500 BTU/HR.)

Eg: 15 HP Unit x 2500 BTU/HP = 37,500 BTU/hour

The ambient temperature should be between

50°F and 104°F (10°C to 40°C).