15

14

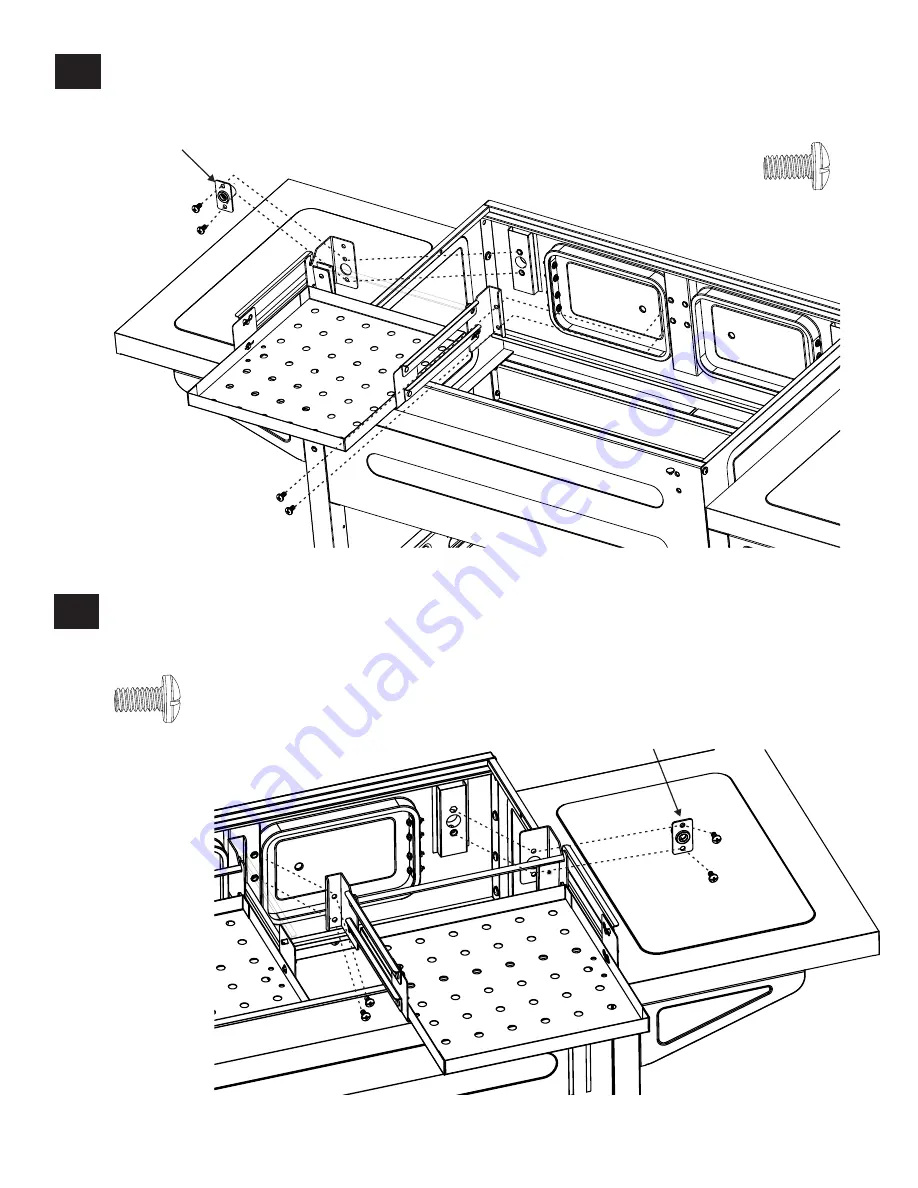

Attach right charcoal pan assy to inside of firebox on left side using (2) 1/4-20x1/2” machine screws. On right side,

also install crankshaft bushing using (2) 1/4-20x1/2” machine screws as shown below. Crankshaft bushing and lifting

paddle must be next to grill end.

1/4-20x1/2’

Machine Screw

QTY 4

Crankshaft

Bushing

Attach left charcoal pan assy to inside of firebox on right side using (2) 1/4-20x1/2” machine screws. On left side, also

install crankshaft bushing using (2) 1/4-20x1/2” screws as shown below. Crankshaft bushing and lifting paddle must be

on next to grill end.

Page 16

15

Right Side (Facing from front)

1/4-20x1/2’

Machine Screw

QTY 4

Crankshaft

Bushing

Left Side (Facing from front)

Summary of Contents for 13301835

Page 22: ...NOTES Page 22 ...