16

17

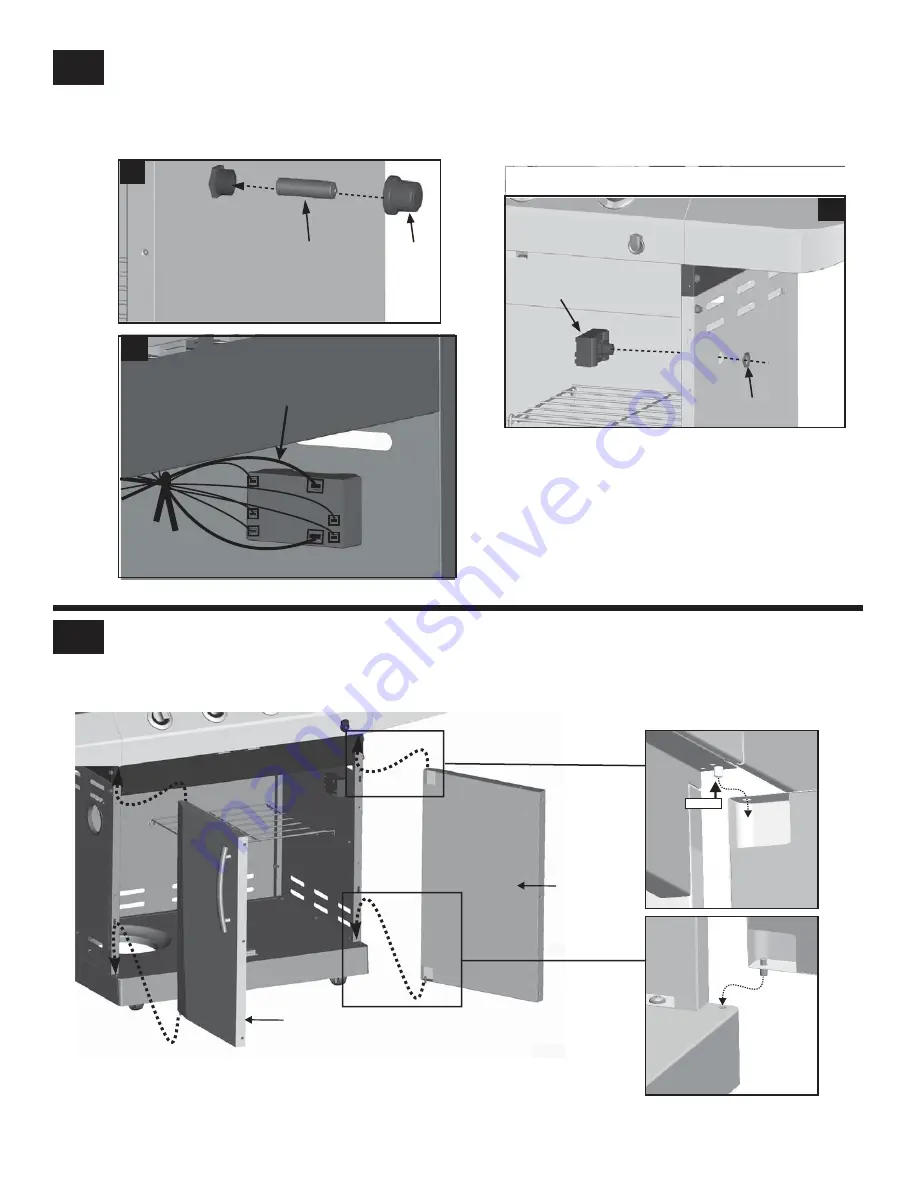

22

Insert hinge pin on bottom of doors into hole in bottom shelf. Press upper hinge pin in front brace, align hinge hole on top of

door, and release hinge pin into door.

1

2

3

4

5

A

B

Release the cap and nut from electronic ignition module. Attach electronic ignition module to the cart right side panel

Insert AA battery into ignition module, negative (

–

) end first. Then put on the cap, shown

B

.

ignition module. Total (2) connections, shown

C

.

module. Total (5) connections. Connect the two wires (A and B) from the switch wiring harness into the back of the electronic

Connect each of the wires from the main burner electrodes, and sideburner electrode into the back of the electronic ignition

with the nut, shown

A

.

+

-

ignition module

Electronic

Nut

Cap

NOTE: Switch terminals are larger than electrode

terminals and should only be installed in

location shown as A, B.

AA battery

Right side panel

A

B

C

Wire

Left door

Hinge pin

on bottom

of door

Top of

door

PRESS

Right door

Summary of Contents for 466231711

Page 29: ...NOTES 29 ...

Page 30: ...NOTES 30 ...

Page 31: ...Warranty Registration Department P O Box 1240 Columbus GA 31902 1240 31 ...

Page 32: ......