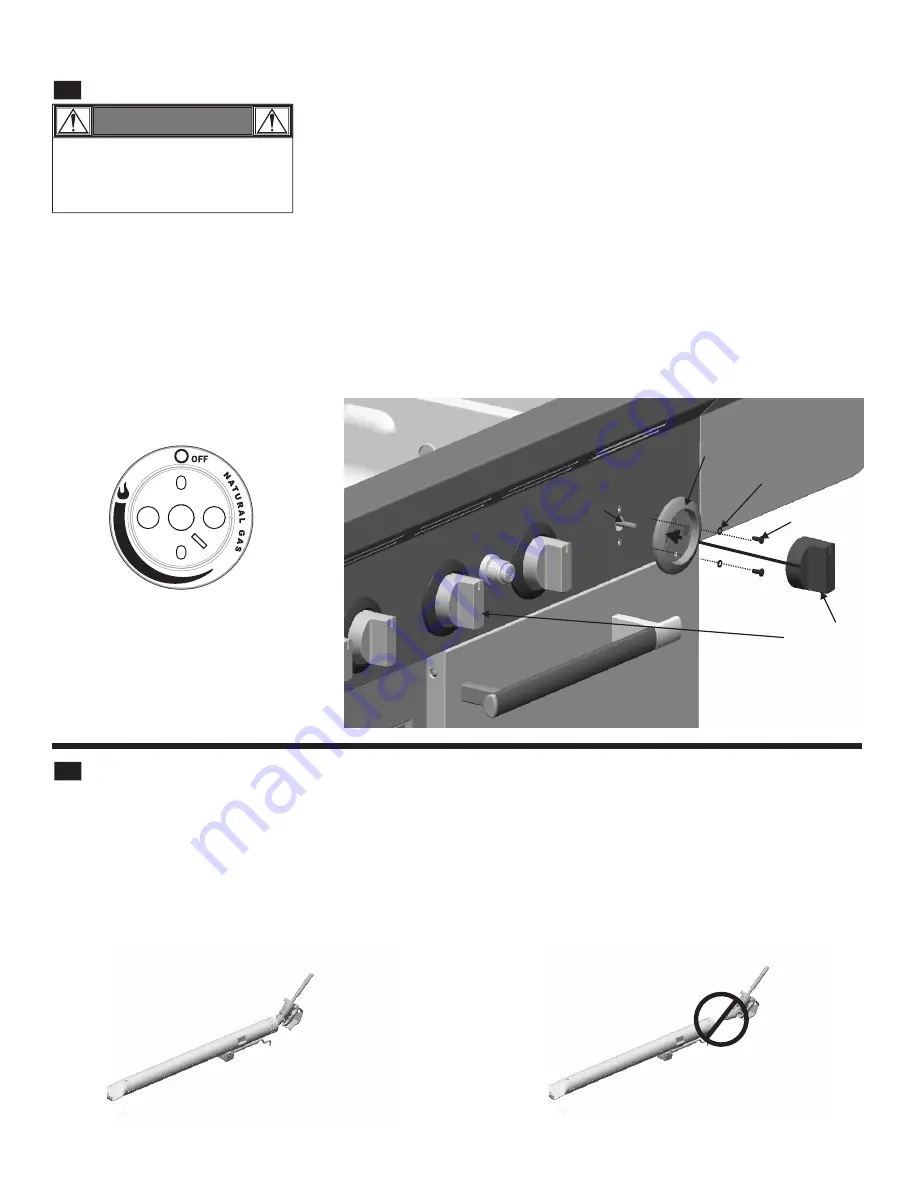

Pull the Tube Burner Control Knob off of Valve Stem.

Remove two Screws and two Washers that secure Bezel to the Control Panel. Save removed Bezel for converting back to LP Tank

Gas.

Install new Natural Gas Bezel provided with Kit (see illustration below) in place of old Bezel onto Control Panel, and secure using

previously removed Screws and Washers. Assure proper alignment with control knob before fully tightening. Note: New bezels will

change the rotation for the control knob to properly control ignition and flames for your grill.

Press Control Knob back onto Valve Stem. Make adjustments needed to Bezel for free movement of Control Knob

Repeat for each Bezel.

B3

Tube Burner

Control Knobs

Bezels

Valve

Stem

Lock Washers

Screws

Contr

ol Panel

B4

Reinstall Tube Burners

Insert Tube Burners into Firebox Burner holes over Valves with Ignitor Assembly downward, making sure Tube Burner engages Valve

properly. See diagram below.

Secure Tube Burners to Burner Brackets with previously removed Hitch Pins. Replace Carryover tubes and secure with Hitch Pins

previously removed. Reference illustration B1.

Incorrect

burner-to-valve

engagement

Correct

burner-to-valve

engagement

Tube Burner

Section B Con’t.

Bezel

WARNING

Bezels must be replaced one at a

time. Removing more than one bezel

at a time may cause misalignment of

manifold.

10

Summary of Contents for 5729581

Page 20: ...NOTES ...