030‐300377 Rev. A

Section LTCMPH-75-802

0316P4

Page 2 of 5

mounted inside the CMPH. Stake mounting is obtainable via molded channel

grooves, which are located at the center of each interior side wall of the base.

These grooves accept most new and existing enclosures’ mounting stakes.

1.5

Installation

See Table 1 to perform a new CMPH enclosure installation. Table 2 de-

scribes a new CMPH installation with stakes, and Table 3 describes an

installation to replace an existing enclosure (rehabilitation installation).

- GROUNDING WARNINGS -

Always follow local codes and company practices for performing proper cable

and site bonding and grounding, and perform all bonding and grounding prior

to other electrical, fiber, and communications connections.

- CABLE DAMAGE WARNINGS -

Be careful not to damage any buried cables or service wires while digging either

to expose cables or to prepare a hole or trench, or while driving stakes.

Buffer tubes and fibers are sensitive to excessive bending, pulling, and crushing

forces. To avoid kinking of buffer tubes and fiber damage or breakage, exercise

great care when working with fiber, and do not exceed or violate minimum bend

radius requirements for fibers, buffer tubes, and cables.

- BODILY HARM WARNINGS -

Risk of serious eye damage! Never look into the end of a fiber optic line or circuit

nor use a magnifier in the presence of laser light or radiation. Always exercise

caution when installing, testing, or performing maintenance on live circuits. If eye

exposure to laser light or radiation has occurred or is suspected, immediately seek

medical treatment by a professional eye care physician.

Shards and cleaved glass fibers are very sharp and can easily pierce the skin. Do

not let cut pieces of fiber stick to your clothing or drop in the work area where they

can later cause injury. Use tweezers to pick up cut or broken pieces of glass fibers

and place them in a container specifically meant for this purpose.

The corrugated metal or armor that may be present in the feed cable is very sharp

at the cut or exposed edges. Extreme caution should be taken to prevent personal

injury. Protective work gloves are recommended when handling armored cable.

Cable and fiber cleaning solvents may contain hazardous materials or harmful

ingredients. Always read and follow the manufacturer’s precautions, warnings,

and instructions when working with cleaning solvents or products.

Table 1. Installing a New CMPH Enclosure

Step

#

Instruction

1.

h

Obtain tools, materials and equipment.

Gather the following equipment to

perform the CMPH installation.

h

216 tool or can wrench

h

Trenching and digging equipment and tools

h

Charles CMPH model

h

Cable grounding materials and tools

h

Scissors, knife or snips

h

Cable opening and management equipment

h

Level

h

Clean, dry, pea gravel

(3/8"‐5/8" diameter)

h

Measuring tape

h

Conduit and conduit caps

(optional)

h

Soil tamping tool(s)

h

Wrenches or socket set

h

Soil for backfill

h

Site cleanup tools

2.

h

Prepare trench.

Do not damage any buried cables or wires while

digging.

Dig and prepare the cable trench, per company practice.

3.

h

Place cables (or conduit or innerduct) in trench.

Follow company

practice to lay, place, and cut any cables and innerduct or conduit.

4.

h

Unpack and inspect equipment.

Remove the CMPH from its packaging.

Inspect the unit upon delivery; if damaged in transit, report the damage to the

shipping company.

5.

h

Disengage the CMPH lock.

Unlock the

CMPH using a 216 tool or can wrench

at the front hex nut‐in‐cup washer

screw; turn the cup‐washer screw

counterclockwise approximately 1/8

turn until it stops. Hold in this position,

then lift the dome up approximately 1"

(enough to disengage the self‐locking

latch) by grasping and lifting the

molded side rail.

Cup‐washer screw

inside dome self‐locking latch

216

Tool

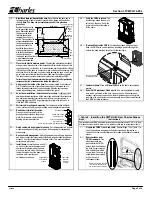

6.

h

Remove the dome.

Set aside the can

wrench after slightly

lifting the dome, then

use both hands to

grasp a side rail (rib)

with each hand and

completely lift off the

dome from the base

.

Set aside the dome for

later use.

Pull up

on ribs

Pull up

on ribs

7.

h

Locate and remove red plastic bag

.

Remove the red bag labeled

“

moisture

barrier

"

included with the CMPH

.

Set it aside for later use.

8.

h

Optional - Replacement or rehabilitation mountings only.

For

applications to replace old enclosures, continue with the steps in Table 3.

9.

h

Determine and mark base installation location.

To determine exactly

where to place the base in the trench, use the base itself as a positioning

template by placing it up over the top of the conduit, innerduct, or cables

(route the cables through the base)

and lowering the base to the ground.

Analyze the site and position the base at its proposed final orientation and

horizontal positioning in the trench or hole and adjust accordingly. Mark this

proposed final spot by removing a shallow layer of top soil from around the

outside perimeter of the base about 2‐4 inches wider than the base. Set the

base aside.

10.

h

Dig a hole for the base.

Caution: Avoid damaging buried cables, wires,

innerduct, conduit or ground equipment whenever digging.

At and

within the marked perimeter boundary

,

dig

straight

down to a depth of 9

inches. Do not dig too deep.

11.

h

Stake mountings.

Refer to Table 2 for instructions to install mounting

stakes in Table 2.

12.

h

Put base in hole or trench and route cable(s) through base.

Route the

cables and conduit or innerduct up through the bottom of the base,

then put

the base in the prepared hole or trench.

Note: Ensure the base location allows technician access to the lock and any

equipment installed or to be installed in the CMPH.

13.

h

Verify proper base depth.

Before backfilling, verify the base is at the proper

depth, approximately 9 inches deep. Rest the base on solid or well‐tamped

soil when measuring this distance. Verify the base ground line indicator is at

the same level as the final‐grade ground line. Remove, add, or tamp more

soil as necessary.

14.

h

Level the base.

Verify that the base is level. Check the level in both

dimensions; front to back, and side to side. Make any needed base‐bottom

soil adjustments to bring the base to a level position.

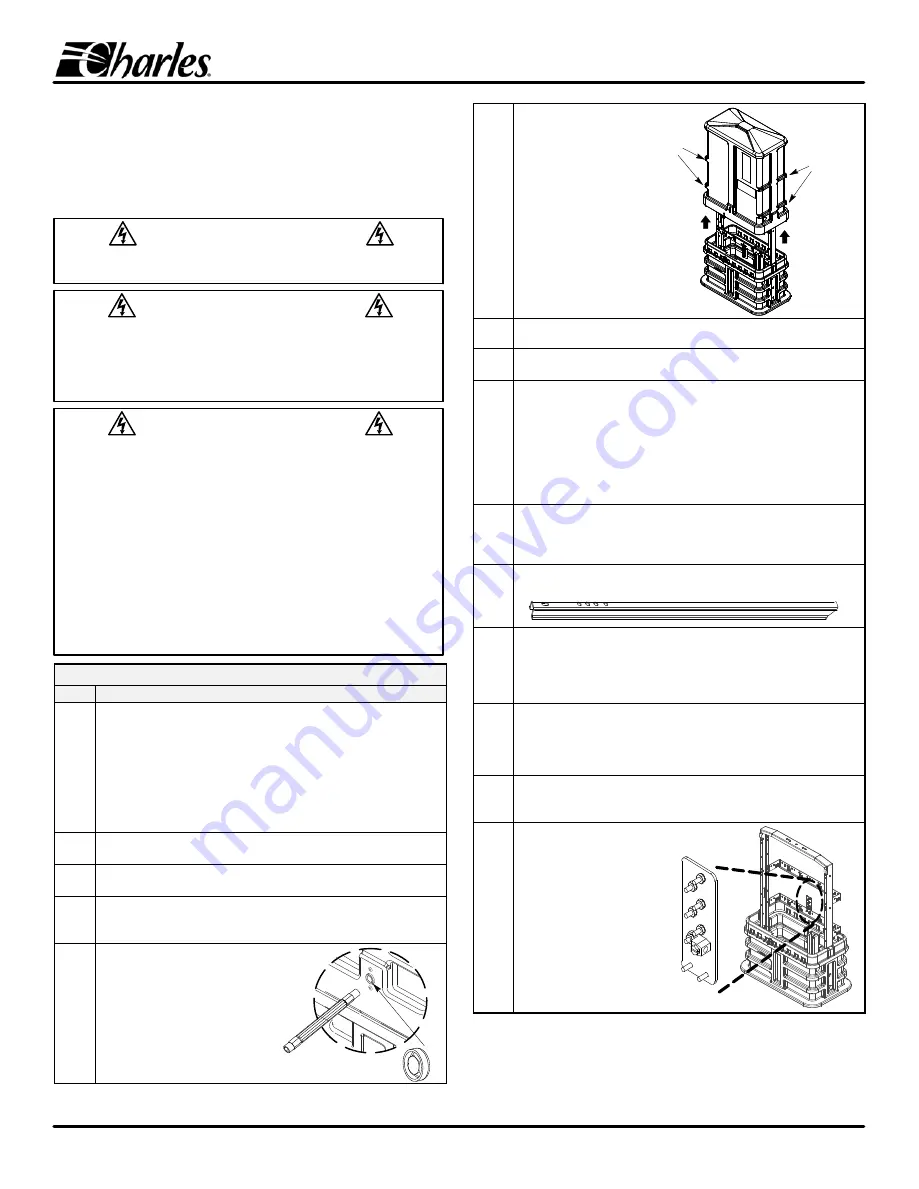

15.

h

Prepare earth ground.

Always

follow local codes and company

practice when preparing earth

ground and when grounding

cables or equipment.

If an earth

ground is not present at the

CMPH site and local code or

practice requires an earth

ground, prepare one now. Attach

the earth ground to the CMPH's

ground lug on the ground plate

(Step 21) using a ground wire of

proper gauge, per company

practice.