030‐300377 Rev. A

Section LTCMPH-75-802

0316P4

Page 3 of 5

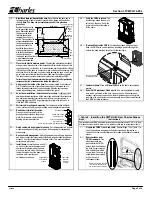

16.

h

Position the base on top

of the gravel and level the

base. Alternately backfill

the base on the inside

first then the outside,

tamping the soil as it is

added. This equalizes the

pressure inside/outside

the base and makes the

base more stable. The

backfill on the outside of

the base should be even

with the Ground Line on

the front of the base.

Inside, add backfill soil to

a point midway between

the first and second ribs.

2 to 3" gravel inside

the base (Step 18)

Base

Top

ÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏ

ÏÏÏÏÏÏÏÏÏ

ÎÎÎÎÎÎ

ÎÎÎÎÎÎ

ËËËËËË

Soil

Pea Gravel

Soil

Backfill and tamp inside/outside the base.

Once the hole has been dug to

the proper depth, a layer of pea rock /gravel must be placed at the bottom of

the hole.

Note: The base can be leveled more easily if it is placed on

gravel first.

8"

7"

Side View

Moisture

Barrier

(see

Step 17)

Base

Bottom

Ground

Line

2"

above

vapor

barrier

1st

Rib

of

Base

ÎÎÎÎÎÎÎÎÎ

ÎÎÎÎÎÎÎÎÎ

Gravel layer

17.

h

Place the red plastic moisture barrier.

The provided moisture barrier sheet

or bag must be placed on top of the tamped backfill soil inside the base. If it is

supplied as a bag, cut the sides so it can be spread over the backfill soil. Bring

it to the edges of the base so it covers as much of the backfill as possible. The

sheet can be cut to fit around any duct or cable entering the base, or an X can

be cut in the center to allow the sheet to be fitted over the cable or conduits.

The sheet serves to prevent excessive moisture from entering the CMPH.

Failure to use the plastic moisture barrier on top of the soil significantly

increases the risk of condensation inside the pedestal.

18.

h

Add gravel to the inside of the base.

Pour approximately 2 to 3 inches of

5/8", or smaller, pea rock or gravel into the base up to the second rib or 2

inches below any innerduct or conduit opening. Keep the duct openings

sealed when adding gravel. Spread out and level the gravel.

19.

h

End of base installation - determine next procedure.

If cable work will

now be performed, continue with the next steps and consult local practices

and equipment manufacturer instructions for the proper procedures. If

further cable work will NOT be performed at this time, skip to Step 24 to

close the CMPH enclosure.

20.

h

Perform cable routing and mounting.

Per company practice and local

codes

,

perform all cable routing, mounting, and management procedures.

21.

h

Bond and strain‐relief the cables.

Ground or bond the cable(s) to the

ground posts provided on the ground

plate. Perform cable strain relief and

bonding per company practice.

Attach earth ground

to ground lug

Attach cable bond

straps to posts

Ground Plate

Posts to attach plate to ground bracket

22.

h

Finish cable work

&

equipment mounting.

Per company practice

,

perform

all cable opening

and splicing procedures

,

and equipment mountings and

connections

.

23.

h

Re‐check cable management.

Verify all equipment and cabling is organized

and will not contact the interior walls of the dome when installed (keep items

at least 1" from the vertical plane of the base collar). This assures safe and

smooth dome placement.

24.

h

Install dome.

Locate the dome and lift it

up and over the interior framework and

equipment. When replacing the dome,

make sure the lock side of the dome is

facing the catch side of the base. Lower

the dome until it overlaps and

self‐latches to the base.

Lower dome

onto base,

latch will

self‐lock

Align bottom of

dome with top

of base

25.

h

Verify the CMPH is locked.

The

dome design allows the dome to

self‐lock on the base. Verify the

dome is locked by attempting to

lift the dome.

26.

h

(Optional) Padlock the CMPH.

For models equipped with an optional

hasp, the CMPH also can be locked by inserting a padlock through the

holes in the hasp provided at the front of the enclosure.

Hasp for padlock

(orderable option)

27.

h

Label outer dome.

Place all ID/warning labels on the dome, per company

practice.

28.

h

End of CMPH placement. Clean up site.

If no more equipment or cable

work will be performed at this time, clean up the site, fill and tamp any

trenches, replace any removed sod, restore the landscape to it's original

condition, pick up all equipment, and optionally leave this document inside

the CMPH for future reference.

Table 2. Installing the CMPH with New Charles Stakes

Step #

Instructions

Charles offers some CMPH models that include 2 mounting stakes (either 30", 36", or 42" long).

All stakes have identical hole patterns. This table describes how to install these models.

1.

h

Prepare the CMPH, trench, and cable.

Perform Steps 1‐10 of Table 1 to

open the enclosure and prepare the hole or trench and the cables or

conduit. Verify the base installation site is ready and suitable for metallic

stakes.

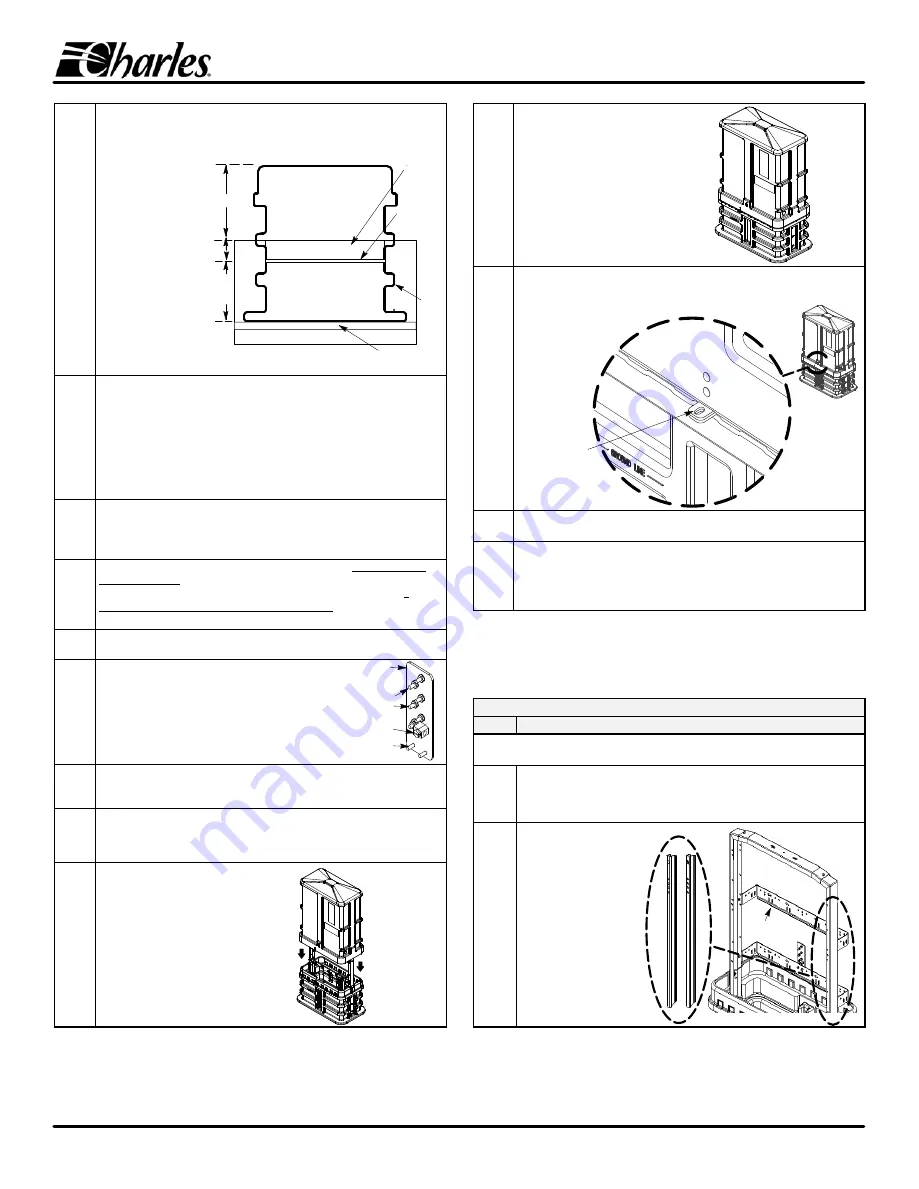

2.

h

Remove stakes from

CMPH framework.

Two

mounting stakes are

packed with the CMPH;

detach them from the base

lag bolts by removing the

nuts and washers which

secure them. Take care to

retain the hardware which

will be re‐used in

subsequent steps.

Remove but retain the nuts

that secure the stakes to

the inside of the enclosure

Fiber‐type bracket

(note offset depth)