030‐300377 Rev. A

Section LTCMPH-75-802

0316P4

Page 4 of 5

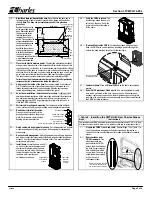

3.

h

Determine which

grooves to use for

stakes.

The base

contains a molded‐in

dual‐purpose groove

at the center of each

wall to accept the

U‐shaped mounting

stakes (as well as the

U‐shaped vertical

channels of the

frame). Per local

company practice

and site conditions,

select two wall

grooves that are

appropriate for stake

attachment purposes

(the grooves on the

shorter side walls are

typically used).

Base

Bottom

View

Open

Inside

Area

Alternate Mounting

Grooves

(generally used

in vault applications)

25.5"

29.5"

2"

1.5"

2"

17"

Base

Top

View

Preferred U-shaped channel

grooves for mounting stakes

4.

h

1.6”

1.1”

Top View

of Stake

Set stake

into groove

Attach stakes to grooves in base.

Set the base on the

ground or a raised surface to access the grooves through

the base bottom. On the inside of the base, remove the

nuts and washers from the bolts (which are 4" apart) that

secure the frame channels in place. On the mounting

stake, the distance between the first and third hole down

from the top of the stake is 4". Insert the top of the stake

into the base, rotate the stake so it will fit properly into the

base groove (so the perimeters match), align the stake

holes with the bolts in the base, and set the stake in place

in the groove. Re‐install the lock washers and nuts that

were removed to secure both the mounting stake and

frame channel in place. Repeat for the other stake.

Base Side View

4

"

1

"

1.3

"

B

olt for frame channel and stakes

4

"

Charles

Stake

Top View of Base

Wall at Groove

1.125”

3”

1”

1”

1.2”

Carriage

Bolt

3

"

5.

h

Verify hole or trench accommodates stake length.

Lift the base and

attempt to place it back in place in the trench or hole. If the trench is deep

enough to accommodate the length of stake protruding from the bottom of

the base, skip the rest of this step. If the hole or trench is not deep enough

to accept the stakes, and the weight of the base is not enough to drive the

stakes the length needed to allow the base to rest at its proper depth, then

once again use the base as a template to mark the exact stake locations in

the ground where more soil must be removed. Remove the base from the

hole, and at the stake‐hole indentations, dig down just enough to

accommodate the length of the stake.

6.

h

Set base in place, bring cables into base.

When the hole is deep enough

for the stakes, again lift the base by its walls or ribs and set it back into the

hole, being sure to enclose or encompass within the base all cables,

innerduct, conduit or equipment present at the site and intended for storage

inside the enclosure.

7.

h

Finish the installation.

Perform Steps 13 through 28 in Table 1 to finish

the installation. Be sure to backfill and firmly tamp soil

into the stake holes

when backfilling.

Table 3. Installing Replacement or Rehabilitation Enclosures

Step #

Instructions

The Charles CMPH has the same footprint as the UPC 1200 series. These instructions

describe how to replace a UPC 1200 with a Charles CMPH. To replace enclosures with

smaller footprints, remove the smaller enclosure and dig a wider hole, as described in

Step 9 of Table 1.

1.

h

Prepare the base, trench, and cables.

Locate the old or existing

enclosure (such as the UPC 1200 series) to be replaced. Perform Steps 1‐7

of Table 1 to prepare the new Charles CMPH enclosure, the hole or trench,

and the cables or conduit (skip Steps 2‐3 if trenching and new cable

placement is not required).

2.

h

Dig around existing enclosure.

Remove the dirt from around the existing

enclosure. Dig deep enough to allow the enclosure to be lifted and

removed.

3.

h

Prepare existing enclosure for removal.

Remove the bottom panels of

the UPC 1200. Locate the mounting stakes and remove the nuts and bolts

from them. Remove all attachments to the enclosure, including cable

supports and tie wraps, bonding connections, and grounding connections.

4.

h

Remove the old enclosure.

Completely remove the existing enclosure.

5.

h

Protect cables and connections.

Per company practice, wrap the existing

splice as tightly as possible without damaging the wire (or fiber)

connections.

6.

h

Analyze condition of existing mounting stakes.

Inspect the existing

mounting stakes for possible re‐use.

If

they are deteriorated, bent, out of

alignment, or have a hole pattern that will not work with the Charles CMPH

base, carefully remove the stakes and install new ones per company

practice (consult Table 2 if desired).

7.

h

Optional - remove the CMPH's horizontal splice bars and/or ground

bracket.

Analyze whether or not it will be necessary to temporarily remove

any of the CMPH's internal, horizontal, supportive splice bars or brackets in

order to fit the existing cabling, connections, splices, and equipment into

the CMPH during the base installation. After base installation, re‐attach the

bars and brackets (Step 10).

8.

h

Set base in place.

Lift the base over the existing cabling and equipment,

and route the wrapped splice and all equipment up through the base bottom

while lowering the base to the bottom of the hole. If the existing stakes were

used, verify they are

inside

the base. If new stakes were attached to the

base, insure the hole accommodates them

.

Perform Steps 13‐14 of Table 1

for the proper base depth and level

.

9.

h

Attach base to re‐used stakes.

Remove the nuts and washers from the 4

bolts located inside the CMPH base that secure the frame channels in

place (2 bolts on each side, 4" apart). Manipulate the base and/or stake

tops so the re‐used stakes fit into the preformed stake grooves in the base

walls. Align the base bolts with the stake holes, and re‐attach the washers

and nuts onto the bolts. Firmly tighten nuts.

10.

h

Attach cables to bars and brackets.

If the splice bars or brackets were

removed, re‐install them now in the best positions to support (and ground)

the equipment. Per company practice, attach or mount all cables and

equipment to the internal framework (bars, brackets) of the CMPH.

Re‐attach any grounding, bonding, and cable connections previously

unattached to remove the old enclosure.

11.

h

Close the CMPH and clean the site.

Perform Steps 23 to 28 of Table 1 to

close the CMPH and restore the site to its previous condition.

2.

CUSTOMER TECHNICAL SERVICE

If technical assistance or customer service is required, contact Charles Indus-

tries by calling or using one of the following options:

847-806-8500 (Tech. Service local)

847-806-6300 (Customer Service)

800-607-8500 (Tech. Service toll-free) 847-806-6653 (Customer Service FAX)

847-806-8556 (Tech. Service FAX)

mktserv@charlesindustries.com (email)

techserv@charlesindustries.com (email) www.charlesindustries.com

(website)