LT-WIC101010

Page 6 of 16

3

rd

Printing

3.

INSTALLATION

3.1.

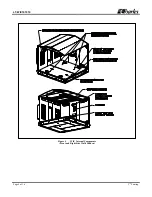

Inspecting the Product

The WIC is shipped as a wide load on a flatbed trailer with shrink wrap.

Unpack the unit, and dispose of the packaging material.

-INSPECTION NOTE-

Visually inspect the unit for damages prior to installation. If the equipment was damaged in transit, immediately report the extent of the

damage to the transportation company.

3.2.

Following and Using Safety Precautions

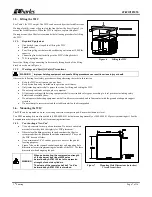

Read the following site and safety tips, cautions, and warnings, then proceed with the paragraphs that follow.

For installation, follow all National Electrical Codes (NEC) ANSI/NFPA 70, local, environmental, workplace, and company

codes, safety procedures, and practices.

Minimum spacing between the accessories and components and the housing for ITE equipment shall be maintained for safe

operation of the equipment when installed in accordance with NEC ANSI/NFPA 70.

Read all instructions, warnings and cautions on the equipment and in the documentation shipped with the product.

Always connect ground connections first.

Do not place this product on weak or unstable surfaces which may allow the product to fall, resulting in potentially serious

damage(s) to persons or product.

Only authorized trained personnel shall install the WIC.

3.3.

Obtaining Tools and Equipment

Obtain the following recommended or needed items for installing the WIC.

Sufficient length and quantities of fiber cable (or pigtails)

Cable scoring, opening, and cutting tools for cable sheathing, shields, wrappings, strength members and buffer tubes

Wire strippers

Crimpers

Cable, tube, wire, and fiber cleaning materials

Protective and/or insulated work gloves

Safety glasses

Tape measure

Marking utensil

#6 ground wire or rod and earth ground materials

Bond strap (optional, from cable bond clamp to bond post)

Any exterior cable strain relief, per company practice

Slotted, hex, and Phillips screwdrivers

Assorted cable ties, clips, or fasteners (optional)

Can wrench (216 type tool)

Forklift or crane for lifting

Level

3.4.

Preparing the Installation Site

Observe the following site preparation recommendations.

Leave adequate horizontal and vertical space between multiple installations to allow for proper cable access, as well as enough

room around the enclosure to open the door(s).

The site must meet minimal personnel and equipment safety requirements.

The distance from the cable entry point should be consistent with local installation practices.

The pad must be able to support the weight of the WIC.

Run all fiber and copper facilities to the site.