www.charltonandjenrick.co.uk

21

LT5878 (ISS 14)

CHECKING GAS SOUNDNESS AND RUNNING PRESSURE.

*power must be connected before proceeding with any soundness testing*

•

Turn on the gas supply to the appliance and check for soundness in accordance with current codes of

practice.

•

Turn off the gas supply at the external Isolation valve.

•

Remove the pressure test point screw from the inlet elbow and connect the pressure gauge.

•

Turn on the gas to the appliance at the Isolation valve.

•

Light the appliance as described in section 2.

•

Check the inlet pressure is 20mbar. +/- 1.0 (Natural Gas) or 37mbar. +/- 1.0 (Propane Gas)

•

Turn off gas supply, at the isolation valve. Disconnect the pressure gauge and replace the pressure test point

screw.

•

Turn on the supply to the appliance and check the pressure test point for soundness with detection fluid.

•

Refit the gas connection cover.

•

Fit the air tray within the location with the burner shelf.

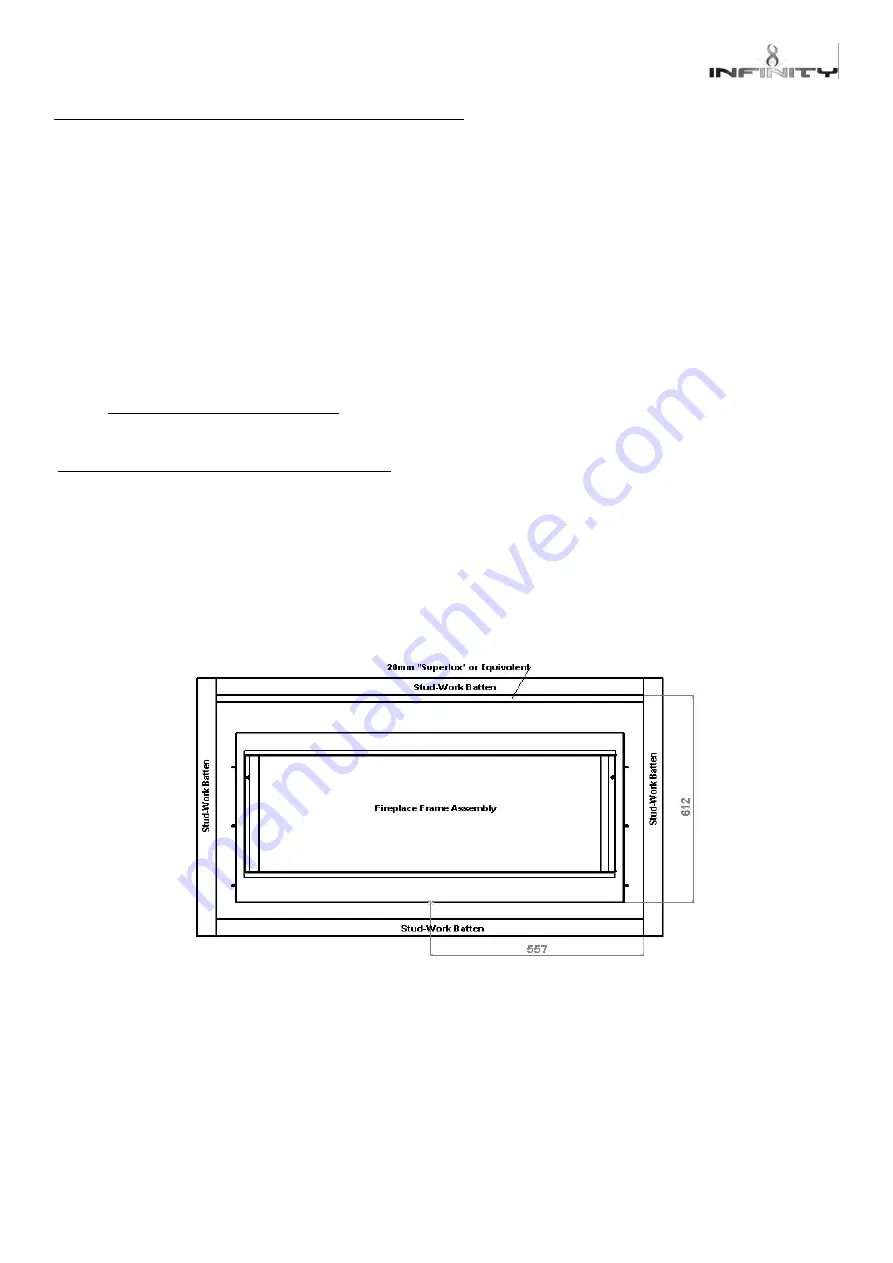

Construction of a false chimney breast front.

•

Using 50mm K.D Sawn stud-work will provide the required rebate.

•

The vertical sides of the stud-work should not be less than 502mm from the centre of the firebox. The

horizontal stud-work should not be less than 764mm from the base of the firebox. This will ensure 50mm

minimum clearance from the sides and 110mm clearance from the top of the firebox is maintained.

•

An insulation material (20mm “Super lux” or equivalent) should be attached to the underside face of the

horizontal stud-work directly above the firebox assembly.

•

Line the opening with 12mm thick non-combustible material.