26

LT7272 (ISS 1)

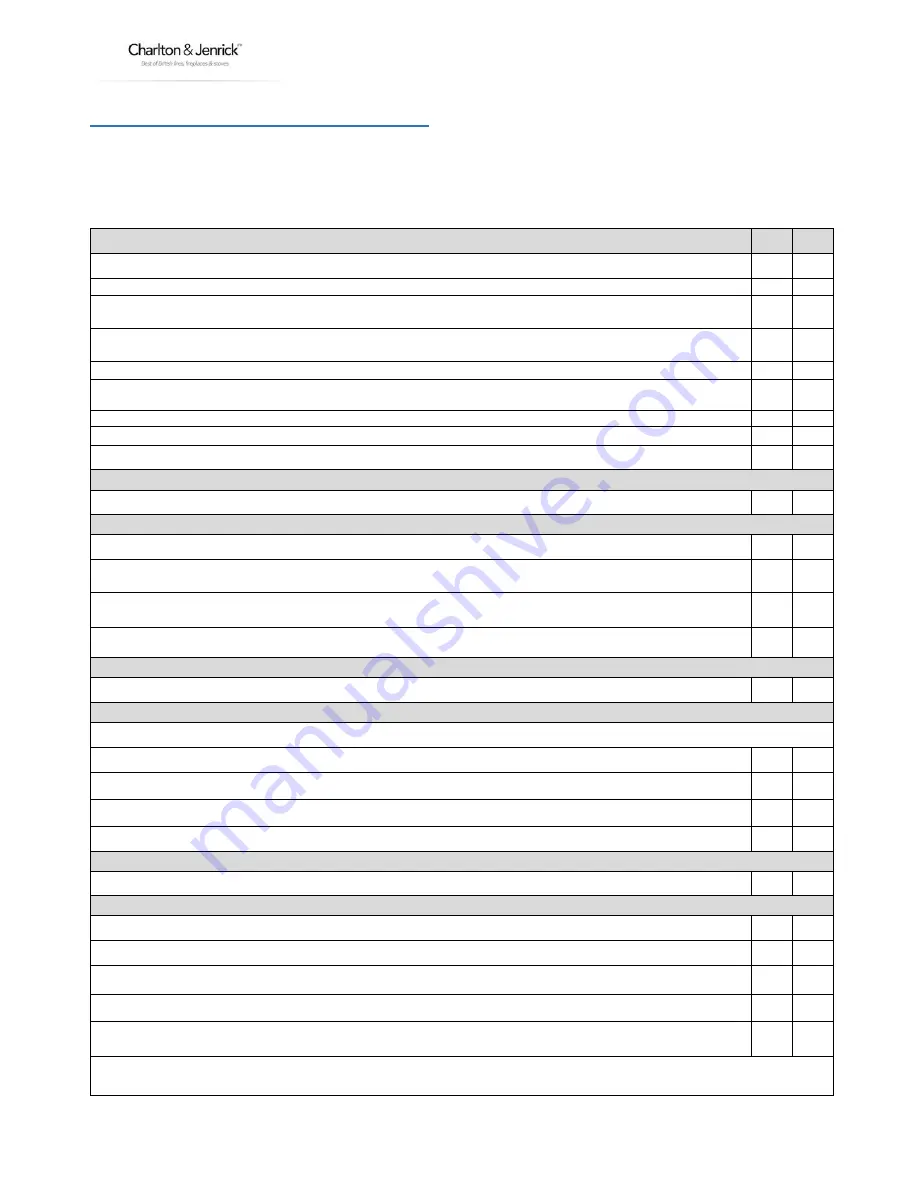

GAS FIRE COMMISSIONING CHECKLIST

This Commissioning Checklist is to be completed in full by the competent person who commissioned the gas fire as a means of

demonstrating compliance with the appropriate Building Regulations and then handed to the customer to keep for future

reference.

Failure to install and commission according to the manufacturer’s instructions and complete this Benchmark Commissioning Checklist will

invalidate the warranty. This does not affect

the customer’s statutory rights.

*All installations in England and Wales must be notified to be Local Authority Building Control (LABC) either directly or through a

Competent Persons Scheme. A Building Regulations Compliance Certificate will then be issued to the customer.

Site Requirements

Yes

N/A

Was the chimney checked to ensure it only serves one flue/fire, has no obstructions and is continuous?

Has any debris at the base of the chimney been removed?

For brick chimney installations is there enough depth for 12 litres of debris, or precast flues 2 litres of debris? (see instructions for

debris gap details)

Have damper and register plates been removed or locked in the fully open position ensuring correct size of flue is maintained?

If previously used for solid fuel has the chimney been thoroughly swept?

If the chimney is pre-cast has the inside of the flue been checked for extruded cement / sealant which must be removed?

Has the fire place been checked for under-floor air supply which must be sealed off?

Has the chimney been inspected prior to fitting the gas fire to ensure that it is in good condition?

Has the structure of the chimney been checked for leakage using a smoke pellet test? (See BS5440-1 for details).

Ventilation

Does the installation

require any additional ventilation requirements as detailed in the manufacturer’s instructions?

Hearth Requirements- where fitted

Is the hearth constructed from non -combustible material?

Is the hearth a minimum of 12mm thick with a minimum floor

to top surface of 50mm?(BS5871) or as per manufacturer’s

instructions?

Is the hearth for open fronted fires a minimum of 760mm wide and has 300mm projecting from the fire opening

(BS6871) or to manufacturer’s instructions?

Mounting height (where applicable) has the fire been installed to the correct mounting height-

as per manufacturer’s instructions?

Firebox and Fuel Bed

Has the fuel bed, coals, pebbles etc. been fitted to manufacturer’s instructions?

Gas Supply

Has an isolation tap/restrictor inlet elbow been fitted for servicing?

Has the gas supply been thoroughly purged prior to connection to remove any debris?

Has a gas tightness test been completed prior to breaking into the gas supply and following completion of

installation?(IGEM/UP/1B)

Record burner gas pressure reading? If only the supply pressure is available a gas rate must be undertaken.(GSIUR REG26/9C)

Record dynamic inlet gas pressure (working pressure) reading (all gas appliances running)

Spillage test

Installation passes smoke match test with any extractor fans turned on (see manufacturer’s instructions)

Installation

Has the gas fire been installed and commissioned in accordance with manufacturer’s instructions?

Has the fire been

installed with the correct clearance to combustible materials, as per manufacturer’s instructions?

The operation of the appliance and controls have been demonstrated to the customer including battery replacement where

applicable?

The manufacturer’s literature, including Benchmark Checklist and Service record has been explained and left with the customer?

Has the appliance been registered with the Local Authority as detailed on the Gas Safe web site and is a legal requirement and

forms part of the warranty?

Customer’s Signature:

Commissioning Engineer’s Signature:

(To

confirm satisfactory demonstration and receipt of manufacturer’s literature)

Summary of Contents for Paragon P3

Page 8: ...8 LT7272 ISS 1 ...

Page 9: ...www charltonandjenrick co uk 9 LT7272 ISS 1 ...

Page 10: ...10 LT7272 ISS 1 ...

Page 24: ...24 LT7272 ISS 1 ...