Charmhigh-V1.0-2016 |

23

All Rights Reserved

9.1.4.

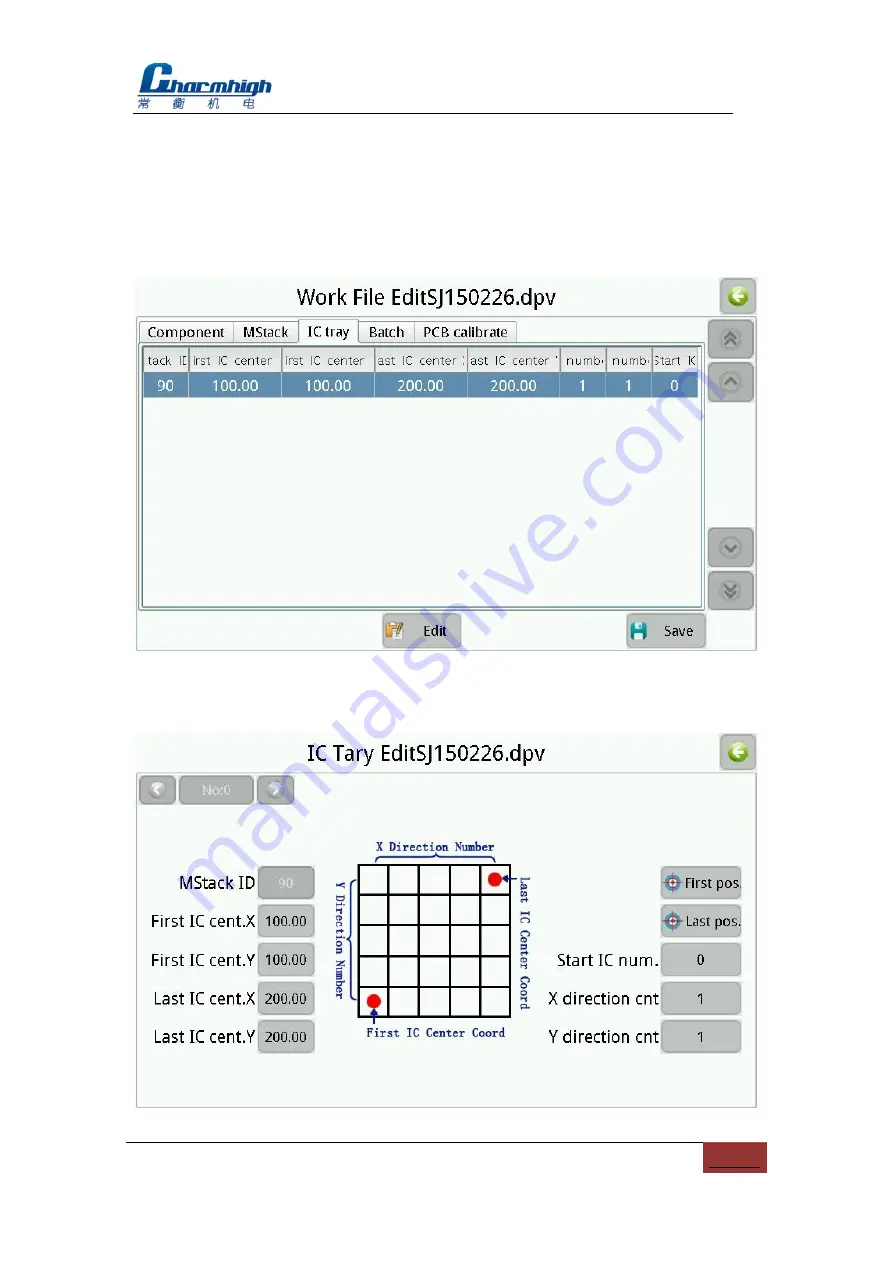

IC Tray

IC tray is particular material stack, i.e. the same kind ICs are hold in IC tray clamp

area as a array, machine pickup material to mount in sequence from left to right and down

to up. Window as show below.

Figure.9-13

Material stack will be added to IC tray list automatically if material stack number is

from 80 to 99 in material stack list, click “Edit” to popup window as show below.

Figure.

9-14