5

4.

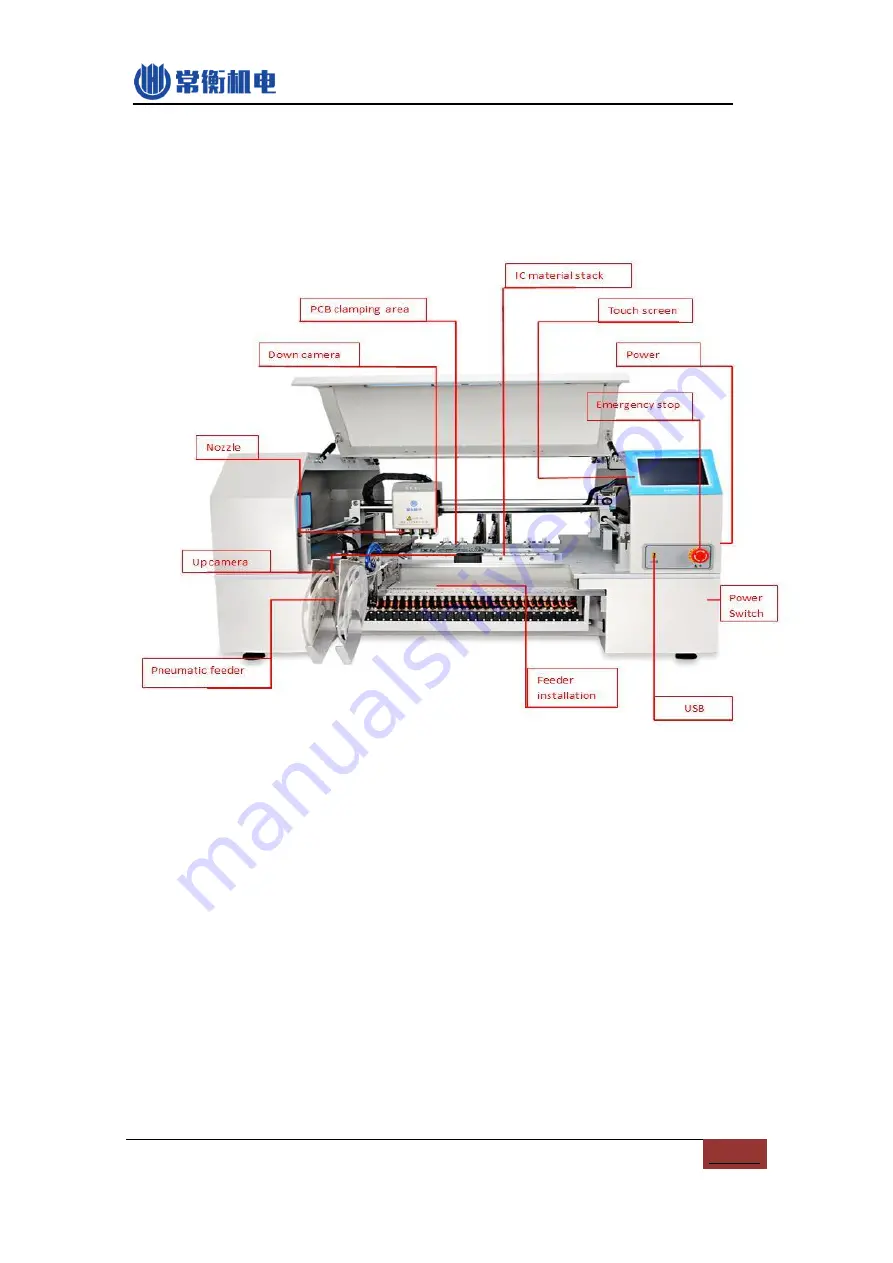

Machine intro

CHMT560P4 machine structure as below:

PIC4-1

(1)

Nozzles

: 4 heads with Juki nozzle

(2)

Down-looking camera

: help positioning and for mark point calibration.

(3)

PCB clamping area:

push the PCB on the end of left corner

(4)

Bulk IC material stack:

put some loose-packed ICs

(5)

Full Touch screen:

Touch pen or external USB mouse supported

(6)

Power:

220v or 110v, fuse inside it

(7)

Emergency button:

press it will emergency stop, rotate to right it will pop out and

back to normal working

(8)

Power switch:

turn ON/OFF machine

(9)

USB:

connect external USB flash

(10)

Up-looking camera:

use for component positioning and angle calibration

(11)

Feeder installation area