Using the Indexing System

The lathe is fitted with an indexing system which allows the spindle to be locked in any of 36 positions (i.e.

at 10 degree intervals). The indexing facility is useful for fluted columns, clock faces and accurate hole

placements.

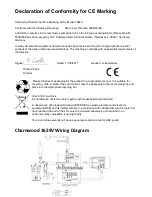

Pin Position A Pin Position B Pin Position C

There are three holes in the headstock casting which will accept the Indexing Pin. These are 20 degrees

apart. The spindle has twelve holes 30 degrees apart and a combination of these will enable you to mark

your workpiece for evenly spaced features.

Pin Position A is unthreaded and will accept the unthreaded end of the Indexing Pin. This position can be

also used to lock the spindle when removing chucks, faceplates etc.

Pin positions B & C are threaded and are used in combination with the threaded end of the Indexing Pin

NUMBER OF

SEGMENTS

ANGULAR

SPACING

DEGREES

PIN PLACING/SPINDLE HOLE COMBINATION

2

180

A1, A7

3

120

A1, A5, A9

4

90

A1, A4, A7, A10

6

60

A1, A3, A5, A7, A9, A11

9

40

A1, A5, A9, B3, B7, B11, C1, C5, C9

12

30

A1, A2, A3, A4, A5, A6, A7, A8, A9, A10, A11, A12

18

20

A1, A3, A5, A7, A9, A11, B1, B3, B5, B7, B9, B11, C1, C3, C5, C7, C9, C11

36

10

A1-12, B1-12, C1-12

Summary of Contents for 1624V

Page 18: ...Charnwood 1624V Parts Drawing ...