that the hearth must extend in front of the stove by at least 300mm

(12 inches) and to the sides of the stove by at least 150mm (6

inches). When the fire door is open, it extends beyond the front of

the stove by:

390mm (15.3in) 414mm (16.3in) 491mm (19.3in)

If in doubt as to the positioning of the stove expert advice should be

sought either from the supplier or the local building inspector.

If the vertical rear flue connector (shown in Fig. 9) is used then the

chimney may be swept through the appliance.

Horizontal lengths of flue must be kept to a minimum and should not

be more than 150mm (6 inches) long. The sealing face of the flue

collar should be coated with fire cement before fixing to the body of

the stove using the two screws provided. The blanking plate must be

removed, sealed with fire cement and refitted, care being taken to

ensure that the fold on the clamping plate is in line with the lugs on

the firebox as shown on the label on the clamping plate. Ensure that

the clamping plate does not prevent the throat plate from seating

correctly. All flue connections must be well sealed.

COVE 1 COVE 2 COVE 3

The fireplace must allow good circulation of air around the appliance

to ensure that maximum heat is transferred to the room and also to

prevent the fireplace from overheating. A gap of 150mm (6 inches)

each side and 300mm (12 inches) above the appliance should give

sufficient air circulation. If a wooden mantelpiece or beam is used in

the fireplace it should be a minimum of 460mm (18 inches), and

preferably 600mm (24 inches) from the appliance. In some situations

it may be necessary to shield the beam or mantelpiece to protect it.

In order for the fire to operate correctly there must be an air gap

behind the appliance of at least 40mm, but be aware that this

distance will need to be greater in some cases to meet Building

Regulation requirements.

There are several ways of connecting the stove to the flue. These are

illustrated in figures 6 to 9.

It is possible to pass a 16 inch diameter sweeps brush through the

appliance but in most back outlet installations it will be necessary to

have a soot door to enable the chimney to be swept. This may either

be in the actual brickwork of the chimney or in the register plate.

Various types and positions of soot doors are shown in figures 6 to 9.

CONNECTIONS TO FLUES

SOOT DOORS

UNPACKING THE STOVE

The stove arrives bolted and shrink-wrapped to its pallet. The

wrapping is first removed, then the stove released from the pallet by

removing the 4 pallet bolts using a 10mm spanner. The pallet brackets

can now be removed from the stove by tilting it and using a 13mm

spanner to remove the bolts. These 4 bolts are required for levelling

on the Low Stand or fixing on the Centre Stand, but are not used on

the Store Stand. The Stove comes with the Low Stand fitted and if

this is to be used, the Stove may now be moved to its final position.

The pallet is intended to be cut up and used for kindling fuel.

FITTING THE STOVE TO ITS STAND

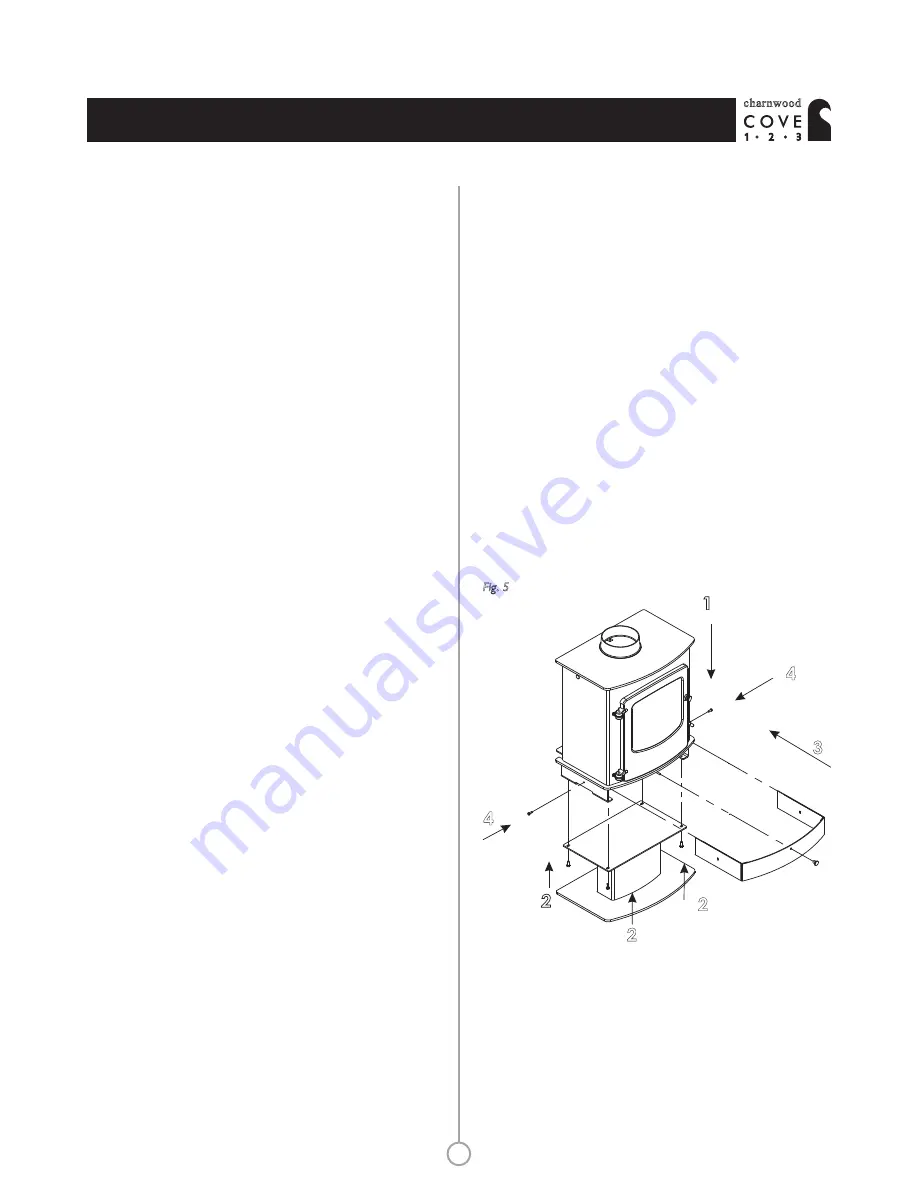

1. Centre stand

The Stand is first positioned on the hearth in the desired position of

the stove. The lower cover must be removed from the stove by first

unscrewing the air control knob, then removing the 6mm bolt on

each side using a 10mm spanner. The Cover may now slide off.

Ensure that the pallet brackets have been removed from the stove,

then lift the stove on to the stand, aligning the 4 tapped holes in the

base brackets with the 4 slots in the top of the stand. NOTE: This

requires at least 2 people. The stove is fixed to its stand using 4 M8 x

20mm bolts and 4 plain washers. A 13mm open ended spanner is

required. Replace the cover, side bolts and Air Control Knob.

1

2

Fig. 5

2

2

3

4

4

®

charnwood

INSTALLATION INSTRUCTIONS

10

Summary of Contents for Cove 1

Page 1: ...Operating Installation Instructions charnwood 1 2 3 ...

Page 2: ......