- 5 -

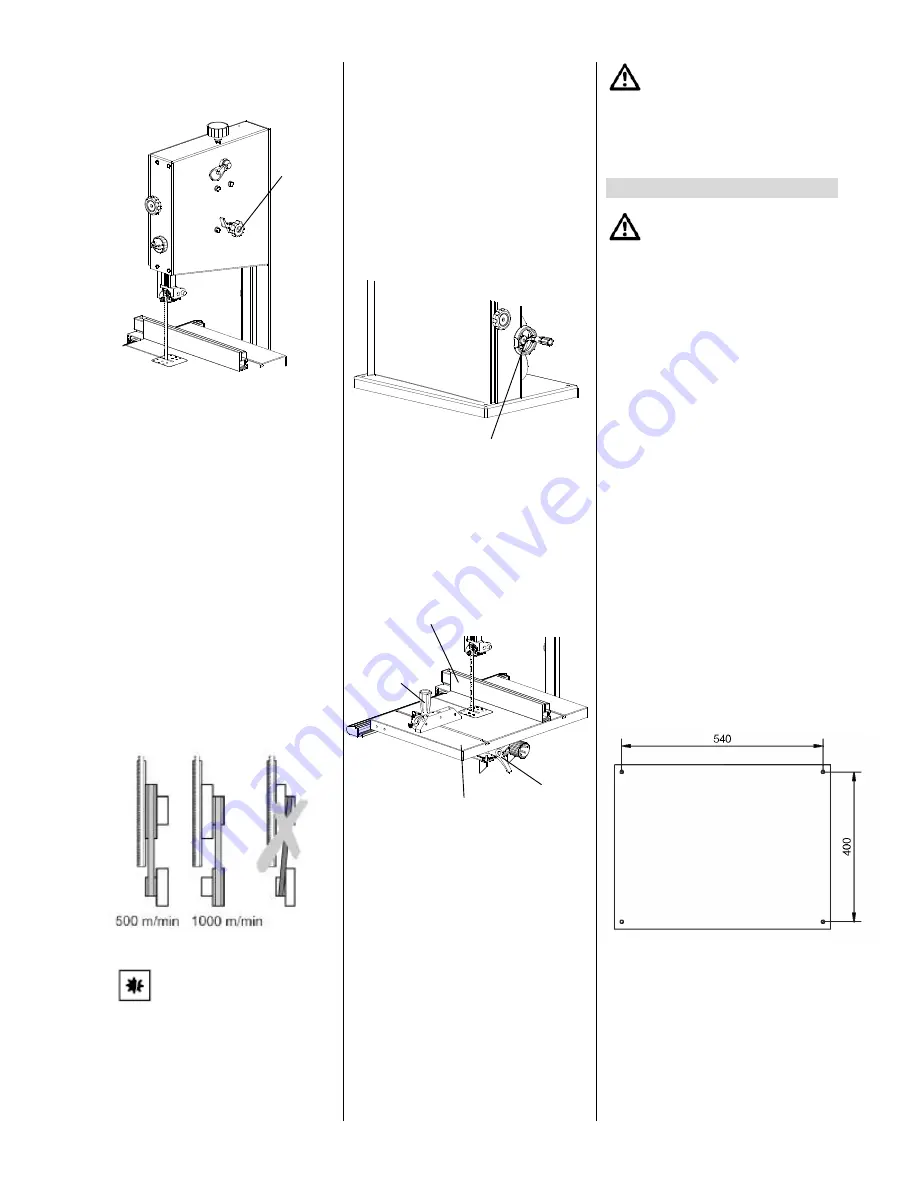

With the setting knob

(33)

the tilt of the

upper band saw wheel can be adjusted, if

necessary. This tracking adjustment is

required to have the blade run dead

center on the rubber tyres of the band

saw wheels:

-

Turning clockwise = blade moves to

the rear.

-

Turning counter-clockwise = blade

moves to the front.

Speed adjustment

By shifting the drive belt the band saw

can be operated at two speeds (see

"Technical Specifications"):

.

500 m/min for hard wood, plastics

.

1000 m/min for all kinds of wood.

Caution!

The drive belt must not run

in a diagonal position; this will damage

the belt

Setting knob for drive belt tension

With the setting knob

(34)

the drive belt

tension is corrected, if necessary

l

turning

the

setting

knob

clockwise reduces the blade

tension

l

turning

the

setting

knob

counterclockwise increases the

blade tension.

Saw table tilt

After loosening the lock screw

(35)

the

saw table

(36)

tilts steplessly through 45

°

against the blade

Rip fence

The rip fence

(37)

clamps to the front of

the bandsaw table; The rip fence can be

used on both sides of the blade.

Mitre fence

The mitre fence

is inserted into the table

slot from the table

’

s front edge. For mitre

cuts the mitre fence turns to60

°

in both

directions For 45

°

and 90

°

miters positive

stops are provided. To set a mitre angle:

loosen lock handle

(38)

by turning it

counter-clockwise.

Risk of injury!

When cutting with the mitre

fence the lock handle must be firmly

tightened.

6. Initial Operation

Danger!

Start the saw only after the

following

preparations

are

completed:

-

the saw is securely mounted ;

-

the saw table is installed and

aligned;

-

the V-belt tension checked;

-

safety devices have been checked.

Connect the saw to the mains supply

only after all of the above preparations

are completed! Otherwise there is a

risk of an unintentional starting of the

saw, which can cause severe personal

injury.

6.1 Mounting

For a firm stand the saw must be

mounted on a stable supporting surface:

1. Drill 4 holes in the supporting

surface.

2. Put fixing bolts through the base

plate and secure with nuts.

Optimal working height and stability is

provided by the steel stand, which is

already prepared for mounting the saw.

Information regarding the assembly of the

stand is given in the addendum to these

operating instructions.

33

34

35

36

37

38