- 6 -

6.2

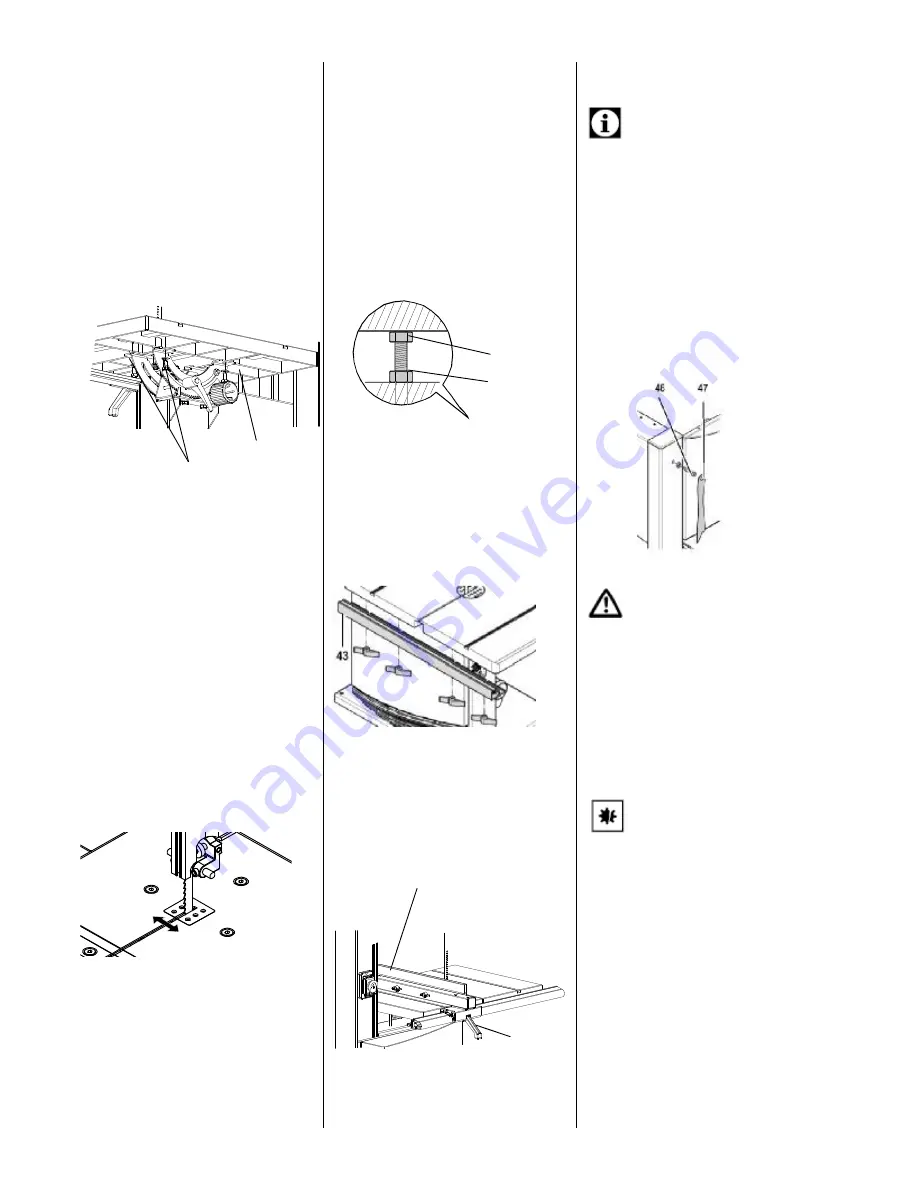

Installing the Saw Table

1. Fit limit stop screw

(40)

to the

underside of the low house .

2. Guide saw table over the band saw

blade and place it on the table

trunnion.

3.

Attach the saw table with four each

screws

(39)

and washers to the table

trunnion.

6.3 Aligning the Saw Table

The saw table needs to be aligned in two

planes

-

laterally, in order for the blade to run

dead centre through the table insert;

-

at right angles to the band saw blade.

Saw table lateral alignment

1. Loosen the four fastening screws

(35)

that hold the lower support of table

trunnion.

2.

Align working table so that the blade

runs through the centre of the table

insert

’

s slot.

3. Tighten the four fastening screws

(35)

again.

Aligning the working table at right

angles to the band saw blade

1. Raise upper blade guide fully (see

"Operation").

Check band saw blade tension (see

"Initial operation").

2. Loosen lock lever

.

3. Using a try square, set the table at

right angles to the blade and tighten

the lock lever

again.

4. Loosen locking nut

(41)

and adjust

limit stop screw

(42)

until it touches

the working table.

5. Tighten locking nut.

6.4

Installing the Fence Guide

Extrusion

Fasten the fence guide extrusion

(58)

with

four each thumb screws and washers to

the saw table.

6.5

Installing the Rip Fence

The rip fence can be used on both sides

of the blade. When the rip fence is moved

from one side of the saw blade to the

other the fence extrusion

(44)

needs to be

reversed.

Place rip fence on the rip fence guide.

Tighten the lock lever

(45)

of the rip

6.6 Installing the Push Stick

Holder

Note:

If the saw is to be mounted on

the stand, the push stick holder can

only be installed afterwards.

1.

Turn a hexagon nut on a cap

screw

(46)

, all the way up to the

unthreaded part of the shank.

2.

Turn cap screw into the hole on the

left side of the band saw.

3.

Tighten hexagon nut hand-tight only.

4.

Hang push stick

(47)

on the cap

screw when not in use.

6.7 Dust collector connection

Danger!

Dust of certain timber species

(e.g. oak, beech, and ash) can cause

cancer when inhaled: always use a

dust

collector

when

working

in

enclosed spaces (air speed at the

saw

’

s dust extraction port

≥

20 m/s).

Caution!

Operation without a dust

collector is only possible:

-

outdoors;

-

for short-term operation (up to

max. 30 minutes);

-

with dust respirator.

-

If no dust collector is used chips

will accumulate, which need to be

removed periodically.

Connect dust collector or industrial

vacuum with a suitable adaptor to the

dust extraction port.

42

41

40

39

44

45