Chassis Plans CPX1-241 Technical Reference

Chapter 1 - Introduction

Page 11

LCD Enhancements

In the CPX family of rugged military grade LCD displays, Chassis Plans starts with Grade A Industrial Quality

LCD panels selected for optical performance, high reliability and long product life cycle. Standard, in order to not

only ruggedize the LCD, but to also enhance the mechanical, optical and EMI properties of the finished unit

Chassis Plans optically bonds a layer of glass to the front of the LCD panel which is coated with an oleophobic

Anti-Reflective (AR) coating. The adhesive is optically clear and refractive index matched to eliminate interface

reflections.

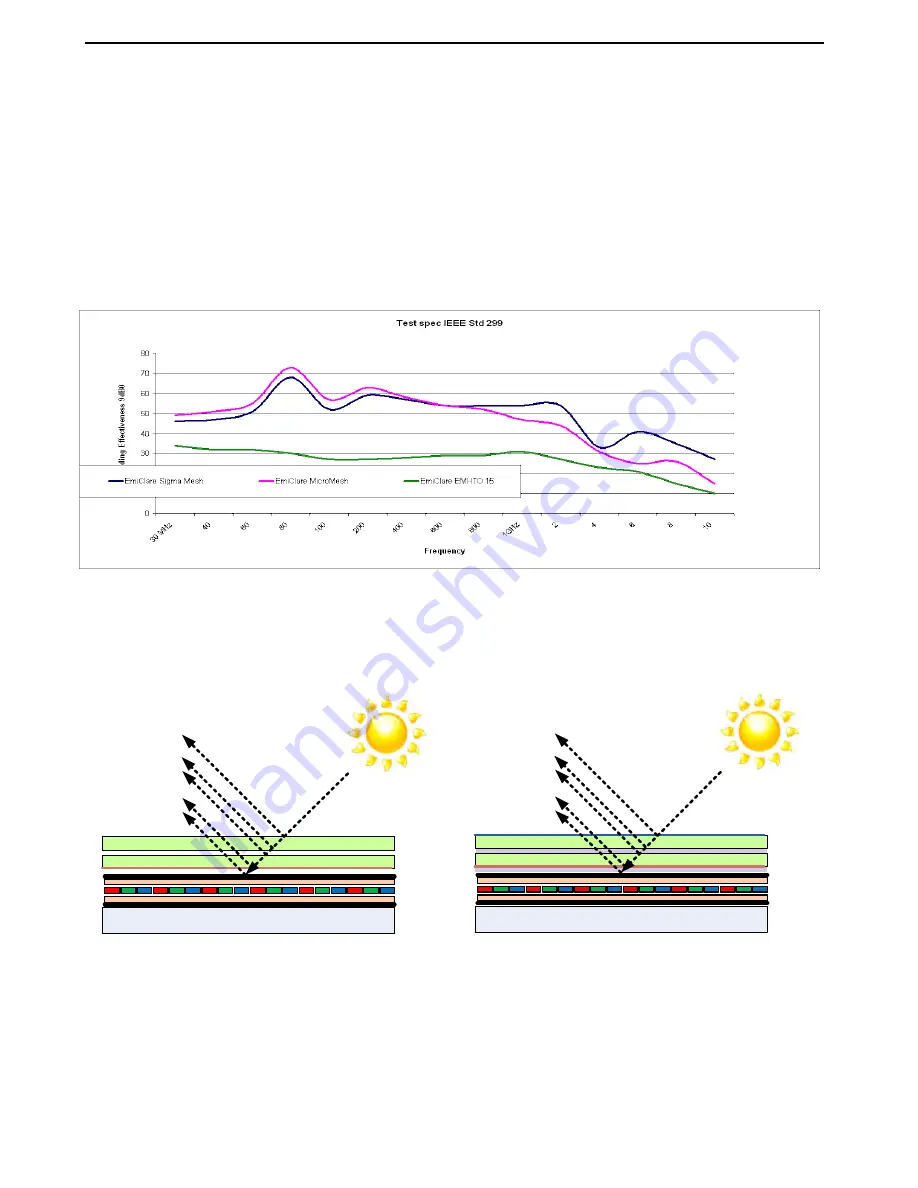

An additional option provides for a fine stainless steel mesh to be embedded in the adhesive for the AR glass to

provide superior EMI shielding. See Figure 2 for attenuation values. The Micro Mesh provides >50dB of

shielding (30 MHz – 1 GHz) with 90% visible light transmission and zero Moiré fringing.

Figure 3 – EMI Shielding Effectiveness of MicroMesh EMI Filter

Figure 4 – Comparison of Reflections with and without Optical Bonding

The resulting structure has greatly enhanced optical characteristics in high ambient light conditions. The optical

adhesive used is a silicone RTV and offers other benefits mechanically to the LCD as well. The adhesive

remains pliable and therefore acts as a shock absorbing medium for the front of the LCD. Together with the

additional layer of glass provides a very rugged composite structure. Another benefit is that should breakage

actually occur the shards of glass will be retained together to prevent injury to personnel. The adhesive also

prevents any condensation from building up in the air gap between the layers of glass which would cause

Reflected

Light

Total

22.5%

4.5%

4.5%

4.5%

4.5%

4.5%

Without Optical Bonding

Or AR Coating

Reflected

Light

Total

0.7%

0.3%

With Optical Bonding

And AR Coating

0.1%

0.1%

0.1%

0.1%