–14 –

5.0 MAKING MEASUREMENTS

The steps involved in making measurements are detailed in this section. The following

sections outline how to setup and prepare your TI-25MX for field use.

An automatic or manual zero must always be performed. The auto zero is an ‘off block’

electronic zero that does not require a zero reference standard. This will most always be

the zero option of choice, as it makes the zeroing process very easy and convenient to

perform. However, the manual zero option offers better accuracy in terms of a reference

point. If the manual zero option is enabled, the probe zero must be measured on the

reference disk (battery disk) attached to the top of the instrument. The zero compensates

for variations in the transducer. In either mode the sound velocity must be determined,

and is used to convert the transit time to a physical length. The sound velocity can be

selected from a material chart in the manual, selected from a short list of common

materials in the TI-25MX, or for greater precision determined from a sample of the test

material that has been mechanically measured. To enter the velocity from a table, look

up the material on the chart in the appendix of this manual and refer to the section below

on Calibration to a Known Velocity. To determine the velocity of a single sample, refer

to the Material Calibration section in section 5.2.

When measuring curved materials, it’s more accurate to calibrate from two test points,

one at the minimum limit of the target thickness and one at the maximum limit. In this

case the reference disk mounted to the TI-25MX is not used. This is called two-point

calibration and is described section 5.2

5.1 Probe zero

Setting the zero point of the TI-25MX is important for the same reason that setting the

zero on a mechanical micrometer is important. It must be done prior to calibration, and

should be done throughout the day to account for any temperature changes in the probe.

If the TI-25MX is not zeroed correctly, all the measurements taken may be in error by

some fixed value. The zero can only be performed with the measurement mode set to

pulse-echo (P-E). Therefore, if the TI-25MX is to use the echo-echo (E-E) measurement

mode and a manual zero is being performed, the TI-25MX will argue by briefly

displaying the message “NO PRB0”.

IMPORTANT NOTE:

The internal zero setting of the TI-25MX, used for the auto

zero mode, can be reset at anytime by performing a “manual zero”, and immediately

followed by performing an “auto zero”.

The TI-25MX is equipped with two zero options:

1. Off Block Zero (Automatic Probe Zero) – When this feature is enabled the

TI-25MX will do an electronic zero automatically, eliminating the need for a zero

disk or reference standard.

Summary of Contents for TI-25MX

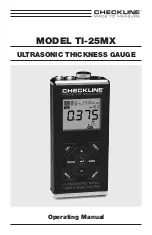

Page 1: ...MODEL TI 25MX ULTRASONIC THICKNESS GAUGE Operating Manual ...

Page 30: ......