TTC Series Torque Tool Tester

Operation Manual

Operators should wear protection such as a mask and gloves in case pieces or

components break away from the unit under test.

Whether the unit is ON or OFF, DO NOT exceed the capacity of the sensor.

NEVER exceed 120% of the rated capacity, or the torque sensor will be

damaged. At 110% of the rated capacity the display will flash a warning.

Measure in line torque only. DO NOT attempt to measure forces at an angle

to the sensor – damage to sensor may result.

Do not attempt to repair or alter this instrument. Warranty will be voided

and damage to the unit may result.

Use and store within the stated temperature and humidity ranges, or

damage and failure may result.

Ensure during testing unit is properly mounted & secured to stable surface.

Mount display with the two integral 8.5 mm mounting holes only. External

sensor models use all four integral mounting holes.

If not using this instrument for extended periods of time, remove the batteries

to prevent potential battery leakage from causing product damage.

The TTC Digital Torque Tool Tester is a simple operation test instrument

for quickly checking torque tool performance up to 590 ft-lb (800 N-m).

The TTC Series provides exceptional accuracy for measuring torque on

various products including torque wrenches, manual screwdrivers,

electric screwdrivers, pneumatic screwdrivers and other torque

controlled power tools.

The TTC’s provide long operation life and power flexibility with the ability

to work from the internal rechargeable battery or included AC adapter.

The TTC’s have six modes of operation: Track for live readings, Peak

which records the highest level over a test, First Peak which records a

reading after a programmed decrease, Auto Peak which resets after a

period of time, Auto First Peak which resets the first peak after a period

of time, Double Peak which provides two separate peak readings from

programmed decreases. Preset operation with programmable tolerance

thresholds for quick pass fail tool test is available in all modes.

The analog bar graph on the backlit, reversible LCD aids users by

providing the resultant torque’s current position compared to the full

scale range along with the direction of the force. Pass/fail icons produce

live test feedback allowing instant determination of the results.

Every tester comes standard with USB and RS-232 outputs. The TTC’s

software enables the uploading of data and the additional statistical

analysis with its auto-calculation of the selected values.

These excellent features make the TTC Torque Tool Testers a valuable

and versatile addition to the production and quality control

departments.

SPECIFICATIONS

Measuring Range:

0.5% - 100% capacity

Accuracy:

± 0.3% of reading

Units of Measure:

N-cm, N-m, in-lb, ft-lb, kg-cm (depending on range)

Measure Modes:

Track, Peak, First Peak, Auto Peak, Auto First

Peak, Double Peak & Preset

Tool Socket Size:

TTC-2/5/10: 1/4” & 1/2” (6.3 & 12.5 mm);

TTC-20/50/100/200: 3/8” & 1/2” (10 & 12.5 mm); TTC-500/800: 3/4”

(19 mm)

Overload Protection:

120% of Full Scale

Sampling Rate:

2000 Hz

Peak Capture Rate:

0.05 s

Display:

160* 128

Dot matrix backlit LCD

Display Update Rate:

10 times/sec

Resolution:

See Chart

Memory:

1000 data

Set Point:

Programmable High and Low Limits

Battery Indication:

Battery icon flashes when low

Charger/Adapter:

Universal USB charger, input 100 - 240 V ac

50/60 Hz

Operating Temperature:

14 to 104ºF (-10 to 40ºC)

Humidity Limit:

20 - 80% RH

Power:

3.6 V dc 1600 mAH Ni-MH

Battery Life:

Approx.

16 Hours continuous on full charge

Output:

USB,

serial port RS-232, High and low limit NPN

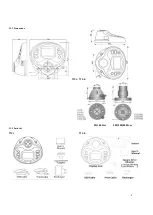

Dimensions:

Display

TTC-I: 7.75 x 7 x 3.3” (197 x 180 x 83 mm);

Display TTC-E: 7.75 x 7 x 3” (197 x 180 x 75 mm);

External Sensor (50, 100 N-m): 4.3 x 3.3”(110 x 83 mm);

External Sensor (200, 500 & 800 N-m): 4 x 3.8” (100 x 98 mm)

Product

Weight:

TTC-I: 3.3 lb (1.5 kg); TTC-E Display: 2.6 lb (1.2 kg); TTC-E-

200/500/800 External Sensor: 4.4 lb (2 kg)

Package Weight:

TTC-I: 6.5

lb (3 kg); TTC-E-200/500/800: 10.2 lb (4.6 kg)

Warranty:

1 year

Certification:

CE