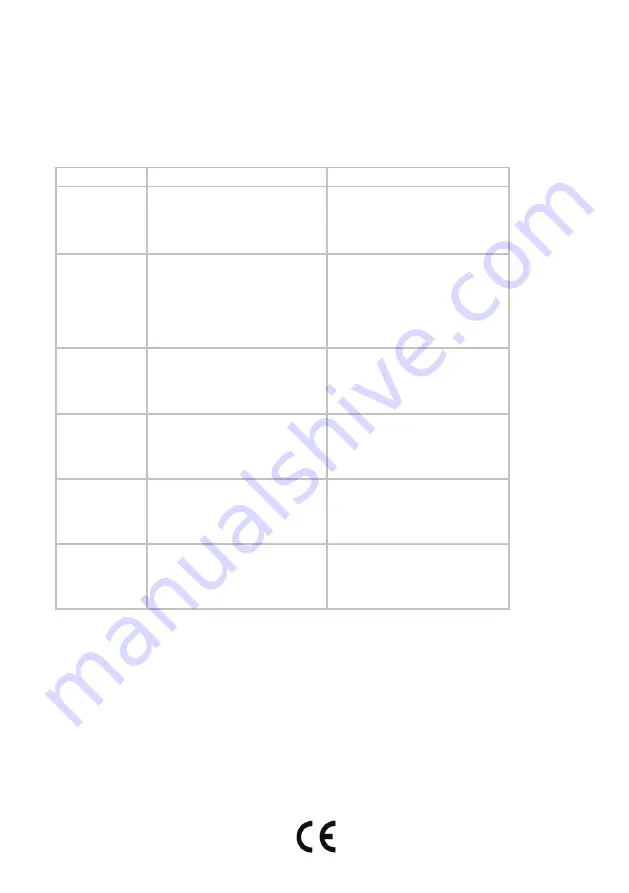

Troubleshooting

The screen of the boiler indicates various errors or problems with the machine. See diag-

nostic table below for futher details.

Error

Description

Action

E-1

High level probe is detected but low level

probe is not detected.

Descale machine & low-level probe.

If it persists, call service agent.

Check low level probe is wired.

Check high & low level are not switched.

E-2

Low level probe not detected.

Wait for machine to fill.

If water can be dispensed then the probe

may be covered in limescale, -descale

machine.

If descaled and error persists then call

service agent.

Check low level probe is wired.

E-3

Temperature sensor (thermistor) is faulty,

missing or not plugged in.

Call service agent.

Thermistor has an open circuit.

E-4

Water is not heating

Element has failed, Call service agent.

Check element for resistance which

should be approx 19 Ohms

E-5

Temperature sensor (thermistor) is faulty

Call service agent.

Thermistor has a short circuit.

E-6

No incoming water

Check water supply is turned on and

mains pressure is above 1bar (14.5psi)

If water supply is OK call service agent as

the inlet valve has likely failed.