6 - INSTRUCTIONS FOR USE

6.1 Safety, cleaning and repair rules

• This appliance is used for the preparation of meals at industri-

al level. Usage and cleaning can be carried only by expert per-

sonnel. Maintenance and repair can be carried out only by

skilled technical personnel.

• These indications must be communicated to all those con-

cerned during internal training.

• Attention! This appliance must be constantly watched over

when being used!

• Grease and overheated oil can catch fire. Use this appliance

only under constant control. Never use water to put out

grease or oil!

• Do not leave the burners running.

• Parts of the appliance and attachments exposed to food

must be cleaned with detergents and rinsed thoroughly with

potable water.

• Do not clean the appliance using water jets or steam,

whether direct or pressurized!

• If the room is being cleaned with water/steam jets or high-pres-

sure equipment, it is necessary to switch off the appliance first!

• Before starting to clean the appliance, disconnect from the

mains.

• Do not use inflammable liquid to clean the appliance.

• Repairs may be carried out only by skilled personnel.

• During repairs, the appliance must undergo voltage

omnipolar insulation (local switch, i.e. safety load cut-off

switch).

• Noise emission values of the appliance in operation are below

70dB (A). This value is compulsory according to certain national

safety standards.

WARNING

Attention!

The manufacturer declines all responsibility concern-

ing mistakes included in these instructions due to translating or

printing errors: the manufacturer also reserves the right to

change the product as he see fits, though without changing its

essential features. The manufacturer declines all responsibility for

any non-compliance with the provisions contained in this manu-

al.

6.2 Start-up

Before using the appliance for the first time, thorou-

ghly clean the tank with lukewarm water and deter-

gent, using a soft cloth to eliminate all trace of the

rust-proofing applied in the workshop. Dry with a clean

cloth.

Check if the water discharge is closed.

Fill the tank with water to the relevant mark.

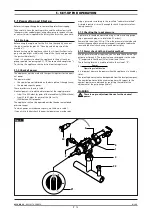

6.2.1 Lighting pilot burner

Press the knob (pos. 21 fig. 1) and turn to the left as far as

.

Keep the knob pressed down while repeatedly pressing the piezo

ignition button (pos. 24 fig. 1) until the pilot flame catches, you can

see through aperture on the combustion chamber. Keep the knob

pressed down for another 15-20 seconds: if the pilot flame goes out

after the knob is released, start again.

6.2.2 Lighting the main burner and temperature adju-

stment

To light the main burner, after light the pilot burner, place the knob

in the maximum or minimum position so that the main burner igni-

tes. Burner power regulation must be done between the max (

)

and min. (

) supply position of easily selectable intermediate

levels.

To shut off the burner, turn the knob to the right to

position,

the main burner will go out.

To shut off the pilot light, place the knob in position “0”.

6.3 Cleaning and taking care of the machine

• Never clean the appliance with jets of water, whether direct or

pressurised!

• Never clean the appliance before it has cooled down.

• Rinse the surface with clean water and a soft cloth to get rid of

all traces of detergent.

• When finished using the appliance, it should be cleaned thorou-

ghly every evening.

• The surfaces and steel parts should be washed in warm water

using a neutral detergent. Avoid using abrasive or corrosive

detergents which could damage the steel.

• Thoroughly dry the appliance.

• Cleaning the appliance daily guarantees perfect long-term ope-

ration.

6.4 Turning the appliance off in case of

breakdown

6.4.1 What to do in case of failure

In case of breakdown or malfunctioning or failure close the gas

cock. Close the connecting cock of the unit. Call the service centre.

6.4.2 What to do in case of prolonged period of disuse

When the appliance is not to be used for a long time, clean thor-

oughly, cas instructed in the chapter 6.5 “Appliance care and fre-

quency of maintenance”, close the connecting cock of the unit.

6.5 Appliance care and frequency of maintenance

Attention! When cleaning, carefully avoid washing the

appliance with direct water jets or high-pressure

water!

Cleaning must be performed when the appliance is cold.

Thorough daily cleaning of the appliance, after disconnecting it, will

keep it in perfect working order and make it last longer. All steel

parts should be cleaned with water and a detergent, using a damp

cloth; do not use abrasive substances or corroding detergents.

Do not use steel wool, which could cause rust to form.

For the same reason, avoid touching the appliance with anything

made of iron. Do not clean with sandpaper and lubricating gel paper.

If absolutely necessary, you may use pumice powder.

If the appliance is extremely dirty, use a synthetic sponge (i.e.

Scotchbrite sponge).

After cleaning the appliance, rinse with clean water and wipe with

a clean cloth.

All maintenance and repair work must be carried out by authorized

technicians only.

The appliance must be checked at least once a year. For this reason,

a service agreement contract is recommended.

6.6 Recommendations for the treatment of

stainless “steel industrial” kitchens

6.6.1 Useful information on “stainless steel”

Industrial kitchens are generally made of “stainless steel” having

the following material codes:

10

· 12

0820_GB_99

- GAS PASTA COOKER

01/2016