5 - SET-UP FOR OPERATION

0820_GB_99

- GAS PASTA COOKER

5.1.5 Power check for operation with liquid gas

Check if the type of injectors used meet the data of the table 1.

Check that the pressure reducer installed in the system has an outlet

pressure which is compliant with paragraph 5.1.2 "Check of power"

(can be checked on the data plate of the appliance or on the table

1).

5.1.6 Operation control

• Start the appliance in accordance with the instructions.

• Check that the appliance does not have any leaks by using a leak-

detecting spray.

• Check ignition and that flame on the main burner lights properly

and is correctly formed, even on low.

• A servicing and maintenance contract is recommended.

5.1.7 Check of pilot flame

For proper regulation, the pilot flame must surround the thermocou-

ple and it must have a perfect appearance; otherwise, check gas

pressure, make sure the injector is clean and has the right diameter

for the gas, see table 1.

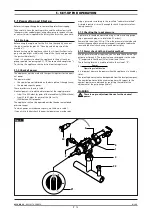

5.1.8 Checking the primary air

The burner is equipped with primary air adjustment. Distance “A”

(fig. 2) see table 1.

Air volume flow is correct when there is sufficient protection again-

st the flame rising when the burner is cold or in case of flashback

when the burner is hot.

5.1.9 Operator training

• Explain and show the user how the machine works according to

the instructions, and hand him this manual.

• Remind the user that any structural alterations or any building

modification or renovation may affect the combustion air supply,

thus requiring a second operation check.

5.1.10 Conversion and adjustment

To change over form one kind of gas to another, for example from

methane to liquid gas, or to another type of gas, the use of suitable

injectors for the main burner is required, in accordance with the

table 1.

The injectors of the main burners and pilot for different types of

gas, marked with the relative diameter in hundredths of mm, are in

an envelope which is provided with the appliance. If injectors are

not available please contact the factory with model and serial num-

ber written on technical data sticker. After transformation or adap-

tation, carry out operating checks as described in paragraph 5.1.6

“Operation control”.

5.1.11 Replacement of burner injector

To replace the injector (pos. 30 fig. 2), open the doors. Unscrew the

injector from the injector-holder using a 12 spanner (pos. 29 fig. 2)

and replace the injectors with one able for the type of gas, see

table 1, install in reverse order. If necessary, disassemble the air

adjustment (pos. 33 fig. 2) by loosening the screws (pos. 39 fig. 2),

this will make replacement easier.

After fitting the new injectors, reset primary air distance “A” (fig. 2)

see table 1, and fasten the bushing with the appropriate screw.

After the replacement check the seal using a leack detector spray.

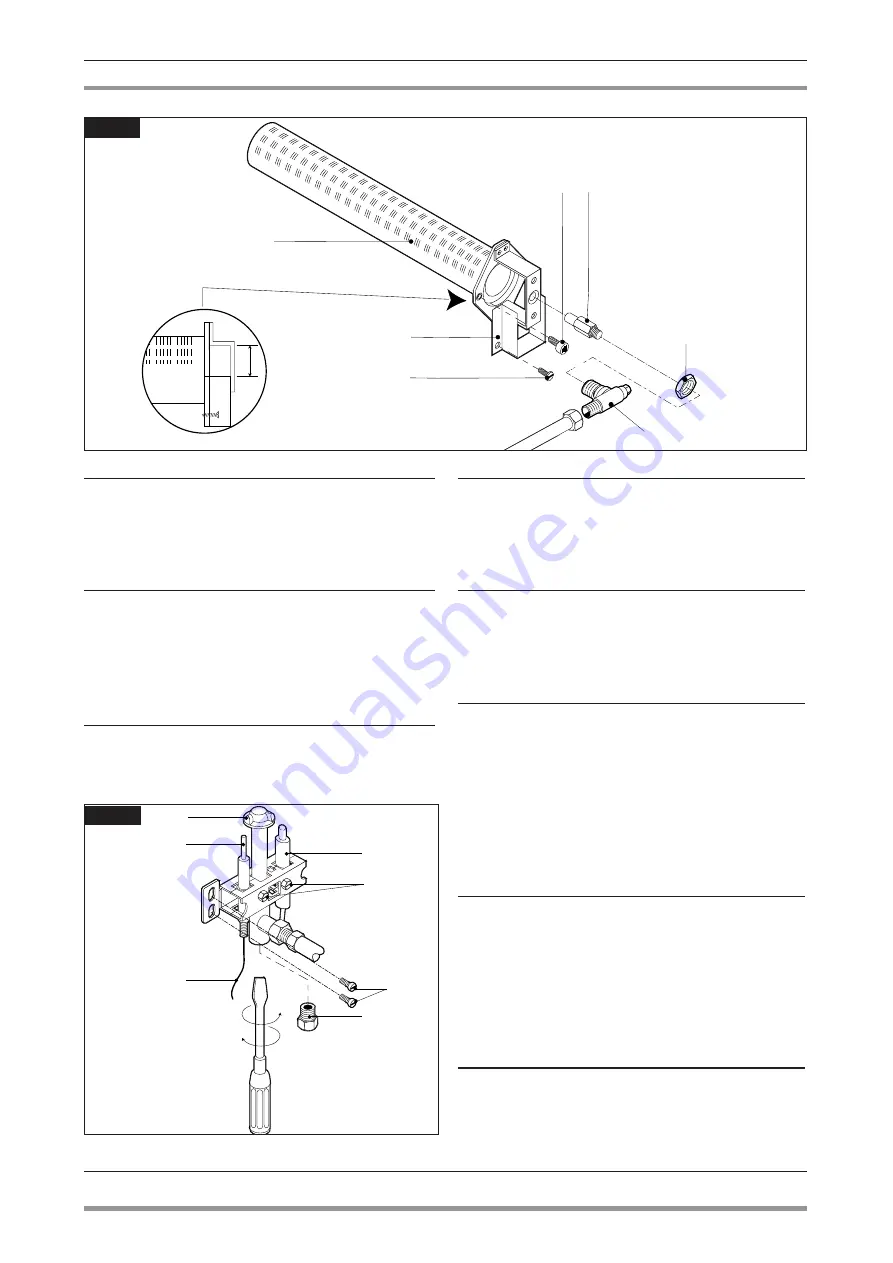

5.1.12 Replacement of burner pilot injector

To replace the pilot injector (pos. 34 fig. 3) open the doors. Unscrew

the nut (pos. 35 fig. 3) and with the help of a screwdriver unscrew

and replace the injectors with one able for the type of gas, see

table 1.

Screw the nut in again ensuring the seal is inserted too.

8

· 12

01/2016

38

37

39

34

36

35

33

Fig. 3

A

32 30

39

33

31

28

29

Fig. 2